It is possible to read the surface pattern of a fence or wall with a 3D scanner and reproduce the same pattern in various locations. This

can also be used for preservation and repair of important cultural properties, as well as for preservation and utilization planning. ( Click here for an example of a fence reproduction.)

It is also possible to reproduce objects without a mold. (Examples: building walls, roofs, cylindrical surfaces, gates, panels, window frames, gateposts, piping panels, etc.)

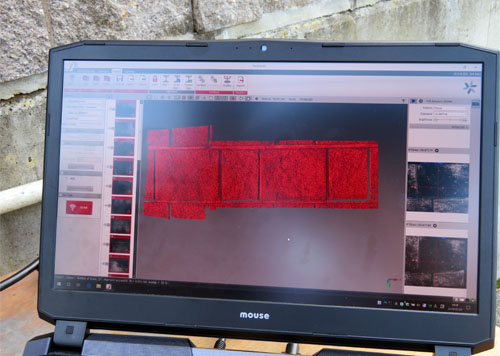

3D scanner captures the surface pattern of the fence

A 3D scanner is used to read the surface pattern of the fence.

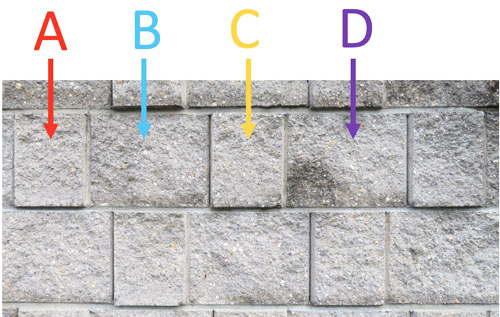

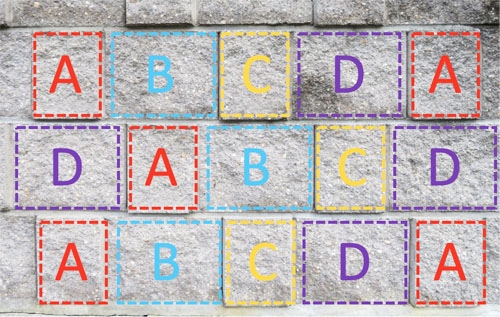

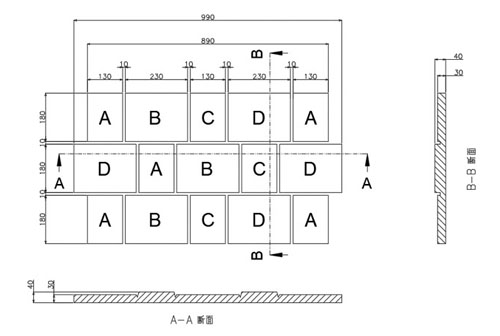

Pattern analysis

Analyze the pattern built into the fence.

You can see that the fence is assembled from four design parts.

The fence is made up of the arrangement of the patterns on the right.

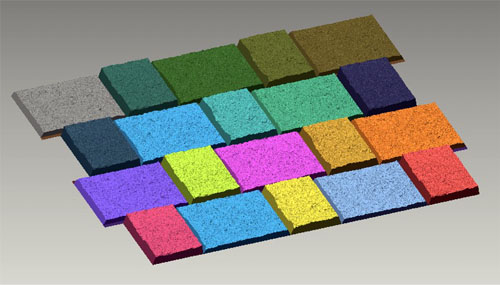

Editing scan data

The scanned data is then edited using software, including

correcting missing parts, determining the layout pattern, correcting distortions, and adding designs.

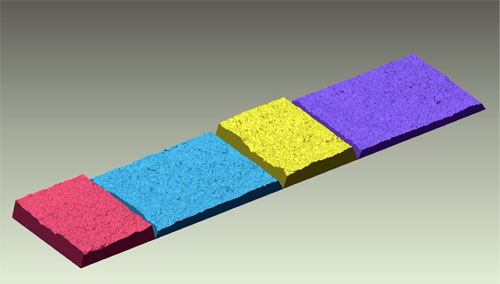

Reverse Engineering

We create 3D models without producing 3D CAD files.

This significantly reduces the design process time, costs, and time to market.

With low tolerances (within 0.1 mm) from the original data, we can achieve a 99% reproduction rate.

Ribs and R can also be added, and we can create 3D drawings upon request, in addition to 2D drawings.

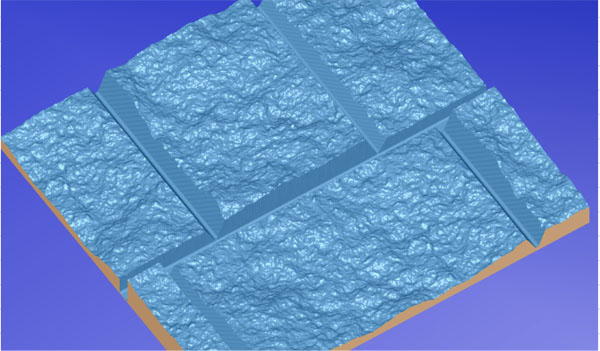

Resin mold processing program creation

Create a resin mold processing program.

Processing was performed with a 0.2 pitch R.

The transferred pattern can be reproduced almost identically to the actual pattern.

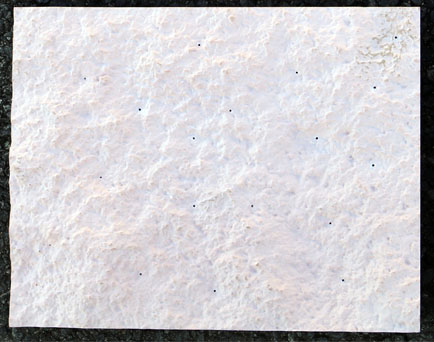

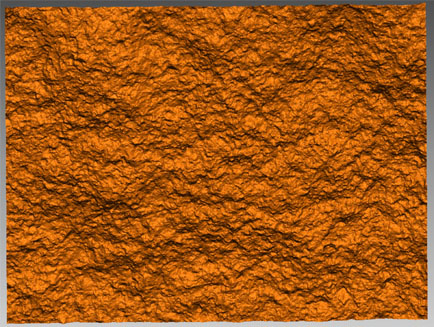

Resin-based processing

Using an NC processing machine, we process the resin mold based on the data.

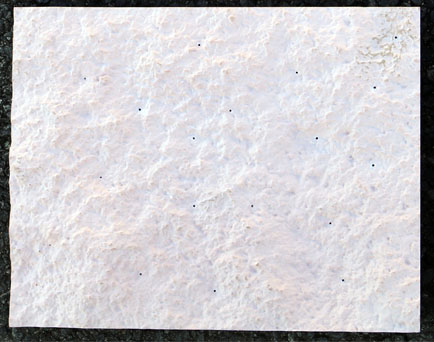

Resin type finished

When you compare the finished resin mold (left) with the actual wall (right), you can see that even the fine bumps and grooves are faithfully reproduced.

casting

This is what was cast using a resin mold.

Painting is also available upon request.

Comparison from data to casting

The actual fence (top left), 3D scan data (top right), resin mold (bottom left), and casting mold (bottom right).

It is possible to read any pattern with high precision and realize the design.

We can also manufacture and reproduce items without molds, so please feel free to contact us.