Reverse engineering is the process of analyzing a product’s structure, creating specifications such as manufacturing methods and blueprints, and then manufacturing the product.

At Asuzac, we use a 3D scanner to create a 3D model and then complete the product.

Reverse engineering creates a 3D model without creating a 3D CAD file, which significantly shortens the design process, reduces costs, and shortens the time to market.

Advantages of reverse engineering

Creating products from 3D models shortens manufacturing time and processes, helping to speed up the development and commercialization of new products. Reverse engineering can also be used to

redesign existing designs and create better products.

Statistics show that reverse engineering can shorten product development cycles by more than 40%.

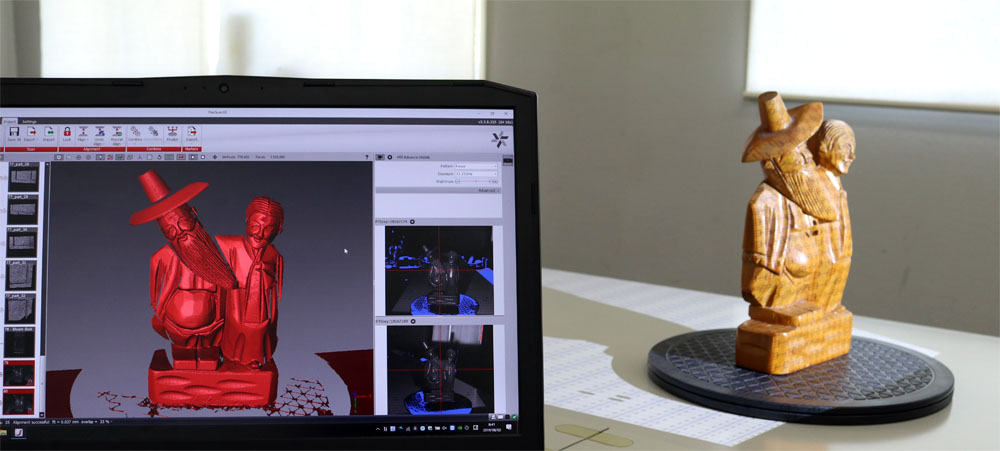

scanning

Scan for what you want to recover.

Scan data

This is mesh data that has been read from an object.

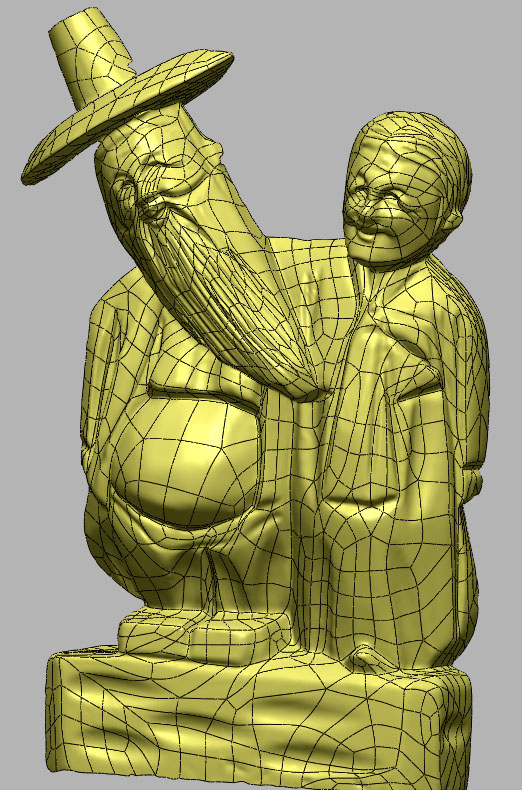

3D CAD data

Mesh data is processed and edited into 3D scan data.

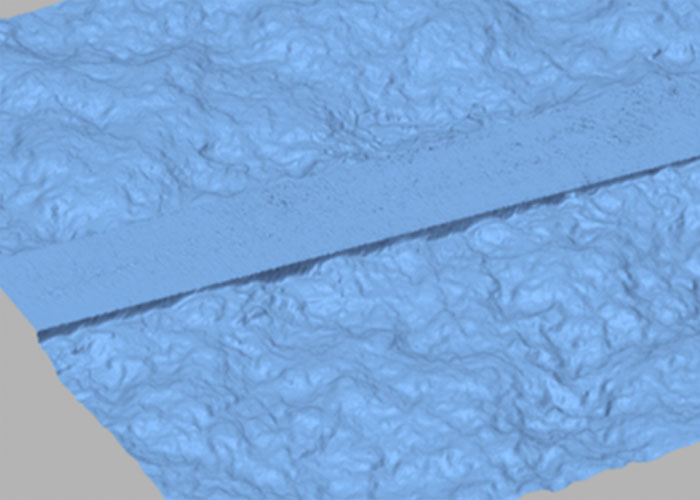

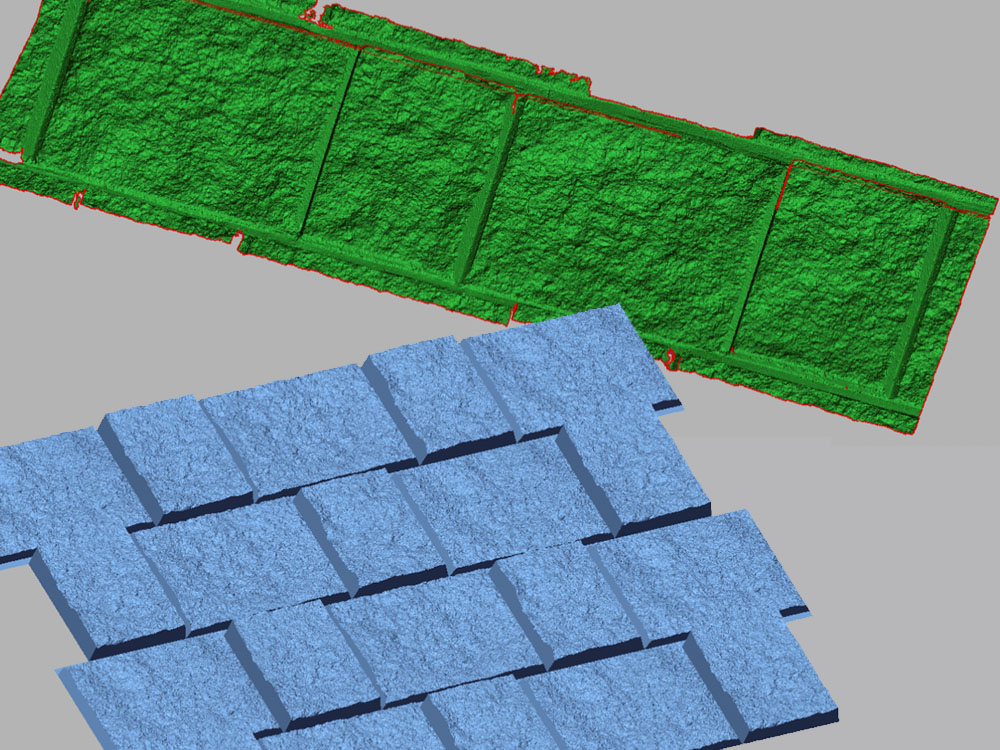

Reproduction of surface patterns

Concrete Casting Mold

This is a concrete casting mold.

Scan data

This is 3D scan data that captures the surface pattern of a mold.

Even complex patterns can be accurately captured.

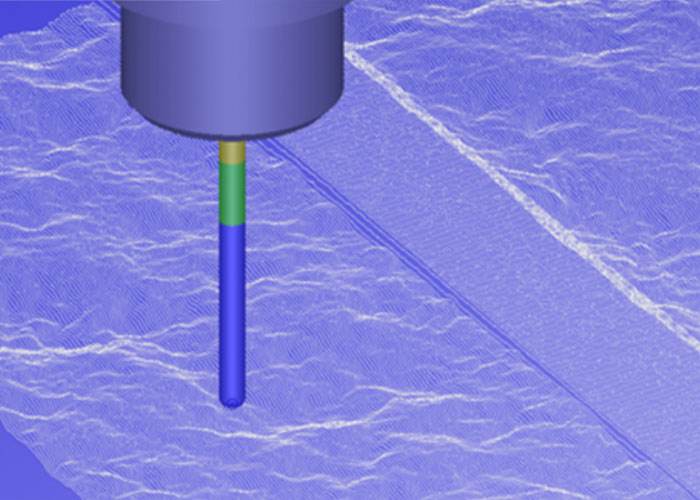

simulation

It simulates how the machine cuts out the material.

Resin mold production

Based on the data, a resin mold was created. This resin mold will be used for casting.

Embedding a pattern

It is also possible to transfer patterns onto product surfaces.

Separately loaded pattern textures can be processed onto the surfaces of gates, fences, panels, etc.

Pattern texture to be transferred

Load the pattern texture you want to transfer.

Texture Data

The scanned texture data can be processed into the surface pattern of the product.