Aluminum castings can be subjected to stress due to their own weight, wind strength, or human contact. This simulation allows you to calculate the stress and deflection (deformation) of the product based on these conditions.

Strength can be confirmed during the design phase, allowing you to tailor the shape to meet your desired strength.

Graphical displays clearly show the movement of the product under pressure and the distribution of stressed areas, making it easier to identify areas that need reinforcement.

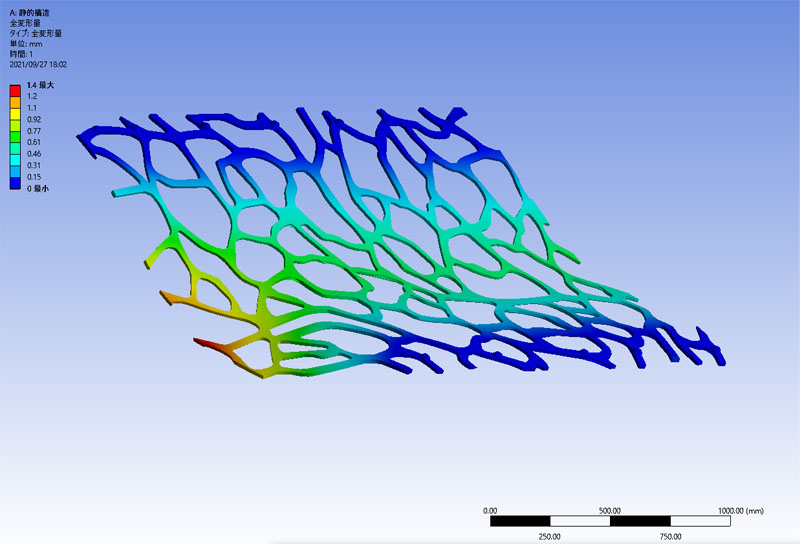

The image below shows the product deforming under its own weight.

(The magnification has been increased to better visualize the shape’s movement. In reality, the product will not bend to this extent.)

The blue areas are where the product is fixed, so the deformation is close to zero, and the redder the color, the greater the deformation.

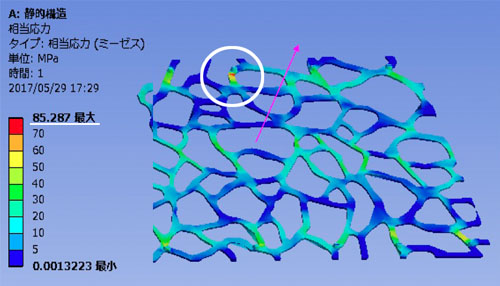

Stress is applied during bending and distortion. For aluminum castings (AC3A), the strength standard is a stress of 70 MPa or less.

This is stress analysis data before the design change.

The red white circle indicates the maximum stress, exceeding 85 MPa.

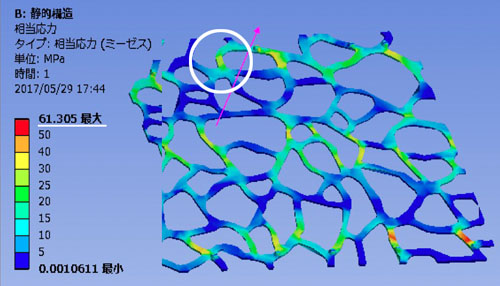

After changing the design and changing the fixing position, we performed another stress analysis.

The maximum value was 61 MPa, resulting in a product design that is more resistant to bending and distortion.

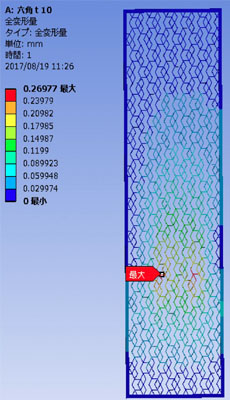

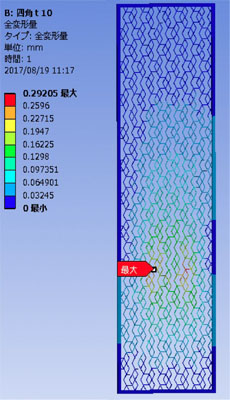

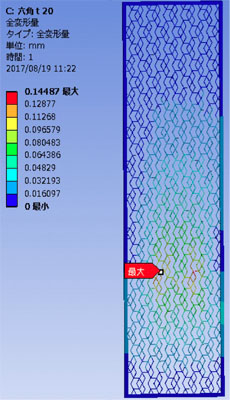

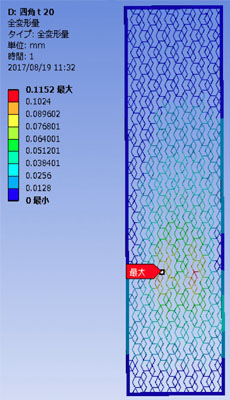

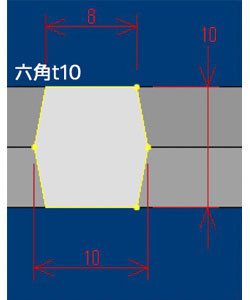

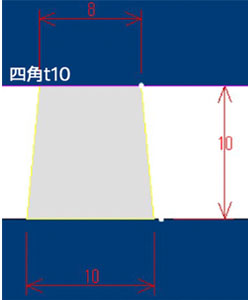

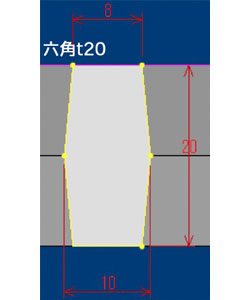

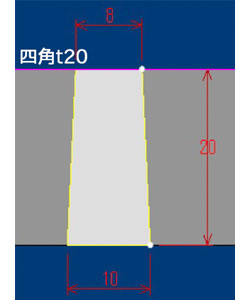

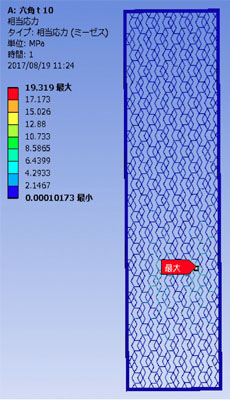

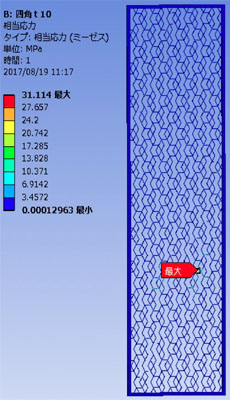

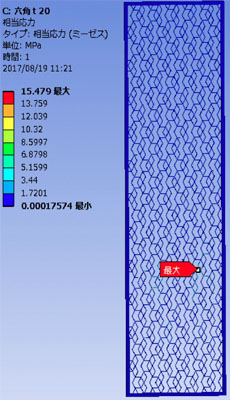

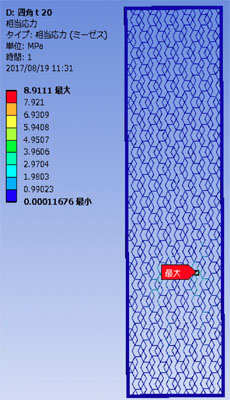

This is a strength comparison of various mesh shapes, such as panels, to determine the maximum force required to achieve the 70 MPa standard.

For each shape, the results were: hexagonal t10: 270 kg (2648 N), square t10: 300 kg (2942 N), hexagonal t20: 1100 kg (10787 N), and square t20: 1100 kg (10787 N).

By changing the product cross-section, it is possible to simulate which shape is stronger.

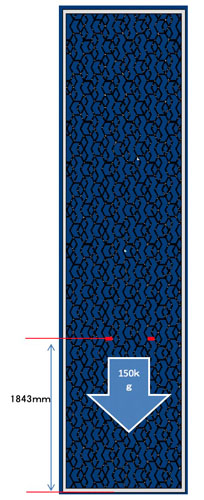

This is the result of a simulation of the stress and deflection of the mesh panel described above, assuming a 150 kg person hangs with both hands approximately 1800 mm from the bottom of the frame. The maximum stress was approximately 19 MPa for hexagonal t10, approximately 31 MPa for square t10, approximately 15 MPa for hexagonal t20, and approximately 9 MPa for square t20.

The maximum deflection was hexagonal t10: approx. 0.26 mm, square t10: approx. 0.29 mm, hexagonal t20: approx. 0.14 mm, square t20: approx. 0.11 mm. As you can see, we can also simulate and analyze deflection and stress depending on the shape at the design stage, so please feel free to contact us for more information.