PPG Liquid vs Powder Coatings: Why ASUZAC ACM Chooses DURANAR® (Liquid) and Coraflon® Platinum (Powder) for Lifetime Architectural Finishes

At ASUZAC ACM, architectural aluminum must endure decades of tropical UV, salt spray, acid rain, and urban pollution while maintaining flawless aesthetics. That’s why we partner exclusively with PPG for two complementary AAMA 2605-certified coating technologies:

- DURANAR® Liquid Coatings – The original 70% PVDF benchmark (two-coat system)

- Coraflon® Platinum Powder Coatings – The next-generation single-coat FEVE innovation

Both deliver ≤5 ΔE color change and ≤8 chalk after 10 years South Florida exposure, but each excels in different scenarios. This comparison explains how ASUZAC ACM leverages liquid PVDF for ultimate color accuracy and FEVE powder for efficiency and matte/anodized effects.

Table of Contents

DURANAR® Liquid PVDF: The 50-Year Gold Standard

System Composition

- Patented inhibitive primer: 0.25 ± 0.05 mil

- 70% PVDF color coat (Kynar 500®/Hylar 5000®): ≥1.0 mil

- Total DFT: ≥1.25 mil (wet-on-wet application)

Proven Performance (AAMA 2605)

Test | Method | Result |

Salt Spray Resistance | ASTM B117, 4,000 hrs | Max 1/16″ creep from scribe |

Humidity Resistance | ASTM D2247, 4,000 hrs | Few #8 blisters maximum |

Acid Resistance | 10% HCl spot, 24 hrs | No attack |

Alkali Resistance | Mortar pat, 24 hrs | No attack |

Detergent Resistance | 3% @ 100°F, 72 hrs | No attack |

South Florida Exposure 10 yrs | 45° facing south | ≤5 ΔE Hunter units, ≤8 chalk, ≤5% film loss |

Pencil Hardness | ASTM D3363 | Minimum F |

Cross-Hatch Adhesion (wet/dry) | ASTM D3359 | 5B – no removal |

Ideal ASUZAC ACM Applications

- Exact color matching to existing buildings

- Deep-tone and high-chroma colors requiring maximum pigment stability

- Projects with complex surface geometries where liquid flow ensures full coverage

- Restoration of historic architecture needing flawless, repairable finishes

Real ASUZAC ACM Installations

- Showa Women’s University 100th Anniversary Gate (Tokyo) – DURANAR liquid in custom bronze for perfect color uniformity on intricate castings

DURANAR SUNSTORM® & DURANAR XL® Liquid Variants

- SUNSTORM®: Two-coat pearlescent/metalescent without clear topcoat

- XL®: Three/four-coat with clear topcoat for coastal/industrial zones (0.6–0.8 mil additional PVDF)

Coraflon® Platinum Powder: The Single-Coat FEVE Revolution

System Composition

- Single-coat FEVE fluoropolymer: 2.0–3.0 mils DFT

- No primer or topcoat required – full AAMA 2605 performance in one layer

Proven Performance (AAMA 2605)

Test | Method | Result |

Dry Adhesion | ASTM D3359 | 5B – no removal |

Wet & Boiling Water Adhesion | ASTM D3359 | 5B – no removal |

Pencil Hardness | ASTM D3363 | F minimum |

Direct Impact Resistance | ASTM D2794 | 3 mm deformation, no removal |

Cyclic Corrosion (4,000 hrs) | ASTM G85 Annex A5 | Pass – Blister ≥8, Scribe ≥7 |

Humidity Resistance (4,000 hrs) | ASTM D2247 | Pass – Blister ≥8 |

South Florida Exposure 10 yrs | ASTM D2244 / D4214 | ≤5 ΔE fade, ≤8 chalk |

Ideal ASUZAC ACM Applications

- Maximum sustainability and efficiency (zero VOCs, 100% reclaimable)

- True matte (5 gloss) or ultra-high gloss (85+) finishes

- Authentic anodized-look effects (silver, bronze, black)

- Complex castings with deep recesses (superior single-coat coverage)

- LEED v4.1 projects avoiding restricted substances

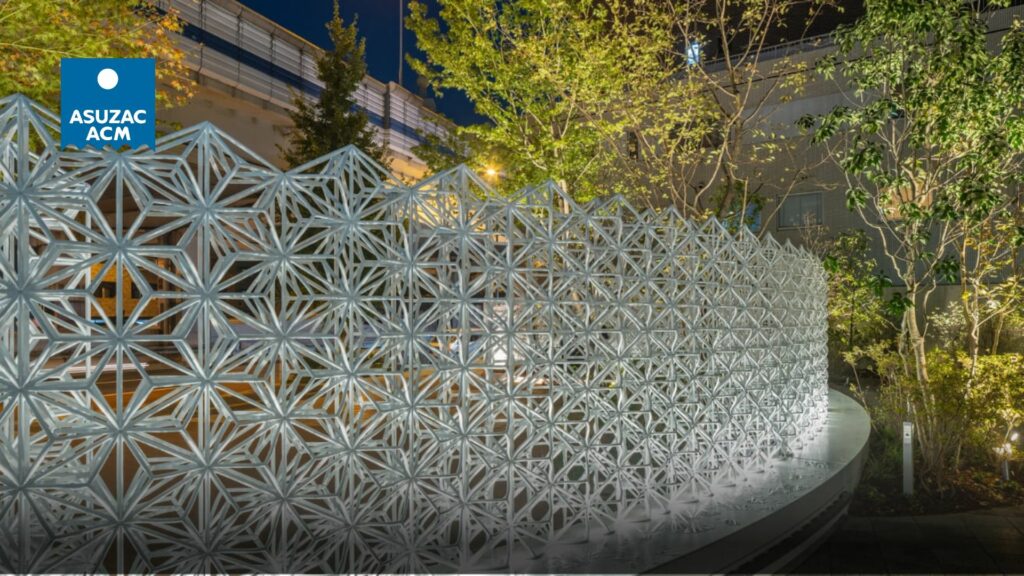

Real ASUZAC ACM Installations

- Kogakuin University Hachioji Campus Facade Panels (Tokyo) – Matte anodized-look in single coat, covering 15,000 m² with zero waste

Liquid PVDF (DURANAR®) vs FEVE Powder (Coraflon® Platinum): ASUZAC ACM’s Selection Criteria

Factor | DURANAR® Liquid PVDF | Coraflon® Platinum FEVE Powder |

Environmental Impact | Low VOCs | Zero VOCs, fully reclaimable |

Application Efficiency | Wet-on-wet, excellent flow | Single-coat, 20% higher transfer |

Gloss & Finish Range | 20–70, limited matte/high gloss | 5–85, true anodized effects |

Color Matching to Existing Buildings | Perfect (original liquid chemistry) | Excellent, but slight powder variation |

Recess & Edge Coverage on Complex Castings | Good | Superior single-coat penetration |

Preferred for | Color-critical restorations, deep tones | Sustainable projects, matte/anodized |

Weather resistance | 20–30 years | 20 years |

The ASUZAC ACM Coating Philosophy: System Selection by Project Type

Project Environment | Recommended System | Rationale |

Urban / General Exterior | DURANAR® Liquid PVDF | Proven color consistency, repairability |

Coastal / Salt Spray Zones | DURANAR XL® Liquid (3/4-coat) | Maximum barrier protection |

Sustainable / LEED Projects | Coraflon® Platinum Powder | Zero VOCs, 100% reclaimable |

Matte/Anodized Aesthetic | Coraflon® Platinum Powder | Widest gloss range, authentic effects |

Metallic/Pearlescent Effects | DURANAR SUNSTORM® Liquid or Coraflon Platinum | Both excel, choose based on efficiency needs |

Historic Restoration | DURANAR® Liquid PVDF | Exact match to legacy finishes |

Real-World Performance: 40+ Years of Proven Excellence

PPG maintains global exposure racks in Singapore (tropical humidity), Dubai (desert UV), Miami (salt spray), and Pittsburgh (industrial pollution). ASUZAC ACM specifies these systems because they deliver:

- DURANAR Liquid: Panels exposed since 1985 show <3 ΔE fade after 40 years

- Coraflon Platinum Powder: Accelerated testing predicts identical 40-year performance in single-coat application

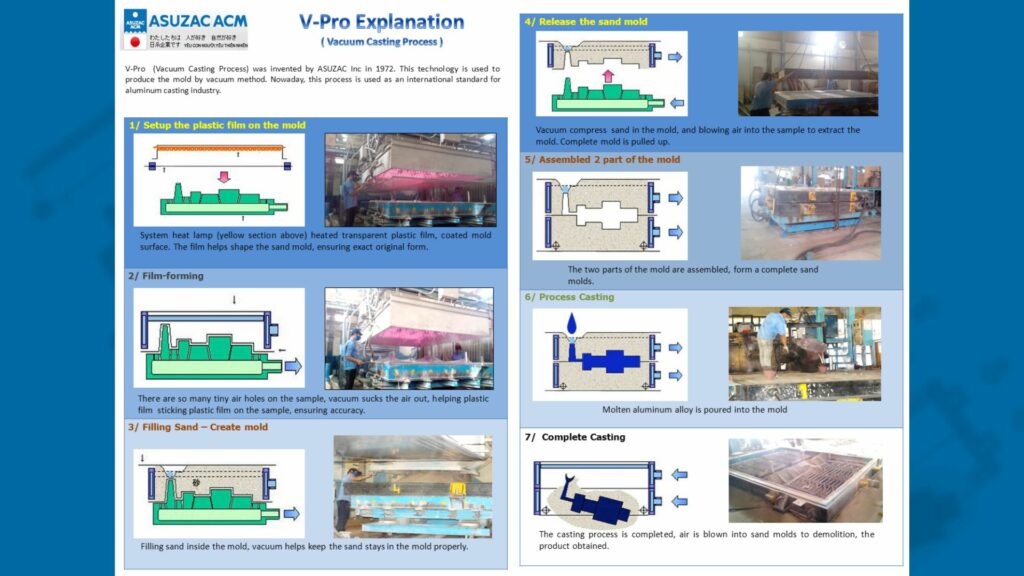

ASUZAC ACM’s Integrated Coating Process

- V-Process Casting: Produces porosity-free, mirror-smooth substrates

- Non-Chrome Pretreatment: E-CLPS 2101 system for adhesion without hexavalent chromium

- PPG-Certified Application: Automated liquid or powder lines with precise DFT control

- Quality Assurance: 100% film thickness verification + batch traceability

- Warranty Registration: Full PPG 20-year AAMA 2605 coverage

Ready to Specify the Optimal Coating System?

Contact ASUZAC ACM’s architectural coatings specialists for:

- DURANAR® vs Coraflon® Platinum side-by-side samples

- AAMA 2605 test data and exposure reports

- Custom color matching and finish recommendations

- Full project cost modeling (liquid vs powder)

Phone: +84-937-076-608

Email: [email protected]

Request samples / quotation: Contact Us

Learn about our casting technology: V-Process Technology

Because the right coating isn’t just protection – it’s permanence.