Need Assistance?

Contact our team today for prompt support or inquiries about our products and services!

No 1A. Street No.8, Vietnam-Singapore Industrial Park, Thuan An City, Binh Duong Province, Vietnam.

Monday-Friday: 9am to 5pm; Satuday: 10ap to 2pm

Table of Contents

Aluminum casting is the process of shaping aluminum into solid parts by pouring molten aluminum into a mold. Once cooled and solidified, the aluminum takes the form of the mold, making it a crucial technique for producing durable and precise components. This method is widely used across industries such as automotive, aerospace, and construction due to aluminum’s lightweight properties, strength, and resistance to corrosion.

There are several aluminum casting techniques, each designed for specific applications:

1. Sand Casting

This traditional method uses sand molds to create intricate and large components. It is cost-effective for low-volume production and allows for flexible design modifications.

2. Die Casting

A high-precision process where molten aluminum is injected into steel molds under pressure. This method is ideal for mass production, offering excellent accuracy and surface finish.

3. Investment Casting

Also known as lost-wax casting, this process involves coating a wax model with ceramic to create a mold, which is then filled with molten aluminum. It is ideal for producing highly detailed and complex parts.

4. Permanent Mold Casting

This technique employs reusable metal molds, offering stronger and more uniform components compared to sand casting. It is used for medium to high-volume production runs.

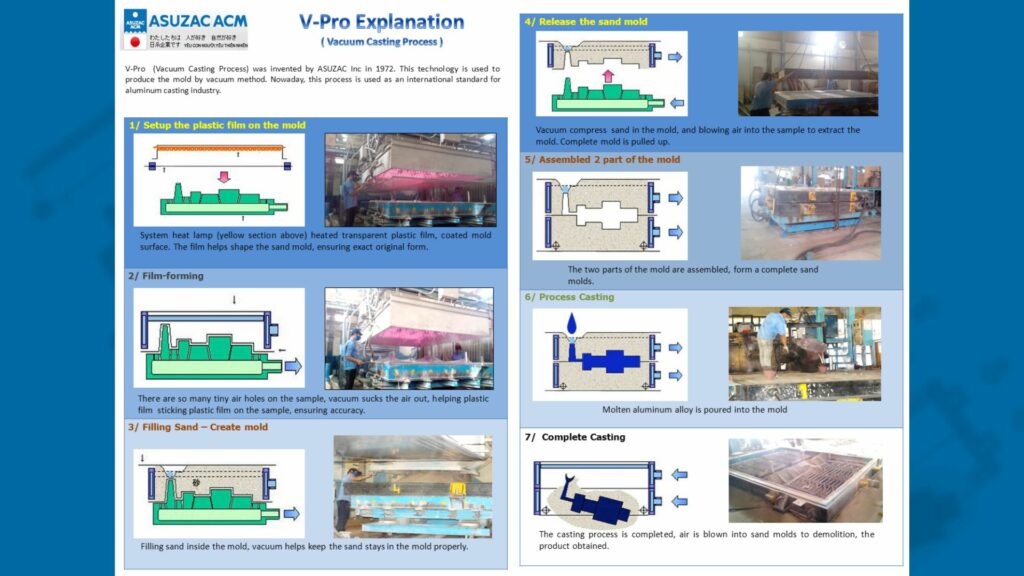

5. V-Process Casting

V-process casting is an innovative method that utilizes vacuum pressure to shape aluminum components without the need for binders in the sand mold. This process results in high-precision castings with minimal defects and superior surface finishes.

ASUZAC-ACM is a leader in aluminum casting, specializing in the V-process casting method. This eco-friendly and energy-efficient approach reduces industrial waste and enhances casting precision. ASUZAC-ACM’s V-process technology is widely used for industrial machinery, automotive parts, and custom aluminum components, ensuring high quality and sustainability in every product.

Aluminum casting is a fundamental process in modern manufacturing, enabling the production of high-quality and complex components. By understanding the various casting techniques and their applications, industries can leverage aluminum casting to enhance performance and efficiency.

Looking for reliable aluminum casting solutions? ASUZAC-ACM offers expert V-process casting services to meet your manufacturing needs.