Benefits of Composite Mold vs. Iron/Steel Mold in Vacuum Casting: Why Composite Excels in Aluminum Casting Molds

The choice of aluminum casting molds significantly impacts the quality, cost, and design potential of vacuum casting outcomes. The benefits of composite mold vs. iron/steel mold in vacuum casting are substantial, with composite molds offering clear advantages in flexibility, surface quality, and production efficiency. ASUZAC ACM, Japan’s leading aluminum casting manufacturer, relies on composite molds within its V-Process to achieve these superior results. This article examines the technical and practical reasons composite molds outperform iron and steel molds, supported by real-world project examples.

Table of Contents

ASUZAC ACM: Japan’s Leading Aluminum Casting Manufacturer

ASUZAC ACM, a 100% Japanese-invested subsidiary of the ASUZAC Group (established in 1946), is Japan’s foremost aluminum casting manufacturer. Since establishing its Vietnam facility in 2005, the company has utilized composite molds in V-Process Technology to produce high-precision, smooth-surfaced aluminum castings. Certified under ISO 9001, ISO 14001, and ISO 45001, ASUZAC ACM maintains rigorous standards in quality and sustainability.

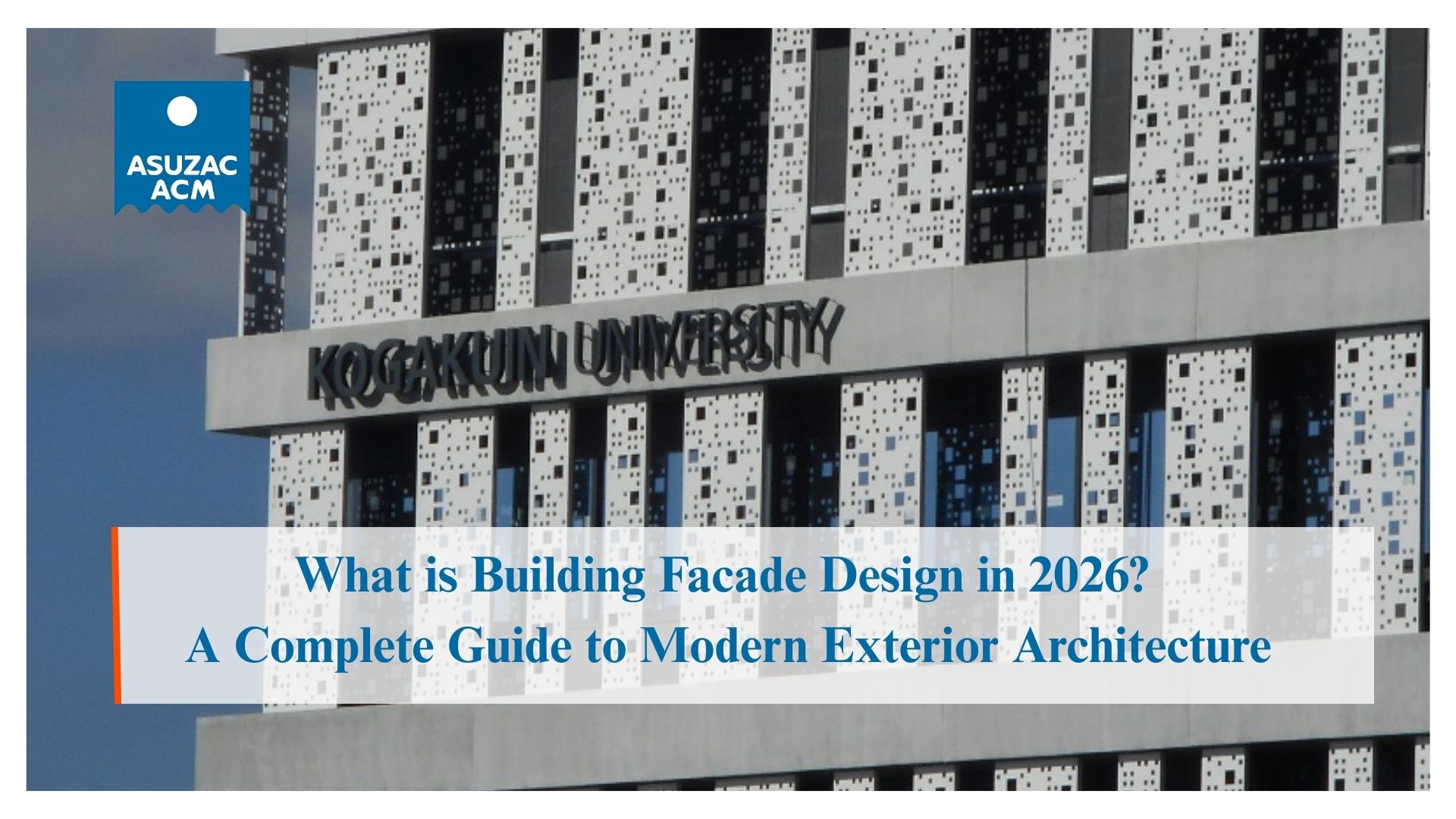

Composite-based aluminum casting molds enable the creation of complex architectural and structural components. Notable projects include the Showa Women’s University main gate, Kogakuin University Hachioji Campus exterior panels, Takada Train Station structural elements, Ryukoku University Omiya Campus fittings, and Shirahama Town’s Chouo Garan annex gates. These demonstrate the practical superiority of composite molds. For technical consultations, visit the contact page.

Technical Advantages of Composite Molds Over Iron/Steel

1. Enhanced Design Flexibility

Composite molds permit zero draft angles and intricate geometries without requiring multi-part construction. Iron and steel molds necessitate draft angles (typically 1-3°) and often complex splitting, limiting design options.

- Why Composite is Better: Supports thin-walled structures and detailed patterns that would be impractical or cost-prohibitive with metal molds.

2. Reduced Weight

Composite molds are 70-80% lighter than equivalent iron or steel molds, simplifying mold preparation and handling. Steel molds frequently exceed 500kg, requiring specialized lifting equipment.

- Why Composite is Better: Decreases physical strain, setup time, and transportation logistics.

3. Superior Surface Finish

Composite molds produce mirror-smooth surfaces with minimal porosity due to uniform vacuum distribution. Iron and steel molds are prone to gas entrapment, resulting in surface imperfections.

- Why Composite is Better: Reduces post-casting finishing by up to 50%, minimizing labor and material waste.

4. Improved Thermal Performance

Composite molds exhibit lower thermal conductivity, allowing controlled cooling that prevents cracking. Steel molds conduct heat rapidly, leading to thermal stress and uneven solidification.

- Why Composite is Better: Shortens cycle times by 20-30% and lowers defect rates to under 1%.

5. Lower Tooling Costs

Composite molds cost 40-60% less to fabricate than precision-machined steel molds and remain viable for 100+ casting cycles.

- Why Composite is Better: Enables economical prototyping and medium-volume production without excessive capital investment.

6. Greater Sustainability

Composite molds incorporate recyclable sand and resin, generating significantly less scrap than steel mold machining.

- Why Composite is Better: Reduces environmental impact and aligns with sustainable manufacturing practices.

Composite vs. Iron/Steel Mold Comparison

Parameter | Composite Mold | Iron/Steel Mold |

Draft Requirement | None | 1-3° minimum |

Weight | 70-80% lighter | High mass, crane-dependent |

Surface Quality | Mirror finish, low porosity | Rough, requires extensive finishing |

Cycle Time | 20-30% faster | Longer due to thermal gradients |

Tooling Cost | 40-60% lower | High precision machining |

Environmental Impact | Low waste, recyclable | High machining scrap |

Real Projects: Composite Mold Excellence in ASUZAC ACM’s Aluminum Casting Solutions

ASUZAC ACM’s aluminum casting molds—powered by composite molds in V-Process vacuum casting—deliver unmatched precision and surface finish in real-world architectural and infrastructure projects. Unlike traditional iron or steel molds, composite molds enable intricate, thin-walled designs with zero draft angles and flawless aesthetics, as proven in these landmark installations:

- Showa Women’s University Main Gate (Tokyo, Japan): For the university’s 100th anniversary, complex aluminum gates and fences were produced using composite molds. Architect Yuko Nagayama oversaw production at the Vietnam facility. The intricate shapes—unfeasible with steel molds due to draft and assembly constraints—were achieved seamlessly. Powder coating provides durable, weather-resistant protection.

- Kogakuin University Hachioji Campus (Tokyo, Japan): Large-scale painted aluminum exterior wall panels were cast with composite molds, ensuring uniform thickness and zero porosity. Rigid steel molds would have restricted panel size and increased weight, complicating installation.

- Takada Train Station (Japan): Structural and decorative aluminum elements were manufactured using composite molds, yielding lightweight, corrosion-resistant components with fine surface detail. Iron mold alternatives would have added significant mass and finishing requirements.

- Ryukoku University Omiya Campus (Japan): Custom aluminum fittings and facade accents were cast with composite mold precision, accurately reproducing cultural motifs while maintaining structural integrity under environmental stress.

- Shirahama Town – Chouo Garan Annex (Chiba, Japan): Aluminum gates and fences for the historic guest house were produced with composite molds, achieving elegant, slender profiles that harmonize with the 19th-century aesthetic.

These projects illustrate how composite molds in V-Process Technology consistently outperform iron and steel in complexity, efficiency, and finish quality.

Why Composite Molds Represent the Future of Vacuum Casting

Composite molds excel in aluminum casting molds because they eliminate the inherent limitations of iron and steel:

- No draft angles or complex splitting.

- Reduced weight and handling complexity.

- Superior surface quality with minimal rework.

- Faster, more reliable production cycles.

- Cost-effective and environmentally responsible.

FAQ: Benefits of Composite Mold vs. Iron/Steel Mold

Q: What are the primary benefits of composite mold vs. iron/steel mold in vacuum casting?

A: Greater flexibility, lighter weight, smoother finishes, faster cycles, lower costs, and reduced environmental impact.

Q: Why are composite molds preferred for complex aluminum casting molds?

A: They support zero-draft, intricate designs without the constraints of metal molds.

Q: How reusable are composite molds?

A: Typically viable for 100+ cycles with consistent performance.

Q: Interested in composite mold casting?

A: Reach out via the contact page for aluminum casting molds.

Q: Are composite molds suitable for large-scale components?

A: Yes—widely used for architectural panels, gates, and structural elements.

Contact ASUZAC ACM for Composite Mold Solutions

Explore the benefits of composite mold vs. iron/steel mold in vacuum casting with ASUZAC ACM:

- Phone: +84-937-076-608

- Email: [email protected]

- Website: Contact Us

- Address: No 1A, St No.8, Vietnam-Singapore Industrial Park, Binh Hoa Ward, Ho Chi Minh City, Vietnam

Conclusion: Composite Molds Lead in Aluminum Casting Excellence

The benefits of composite mold vs. iron/steel mold in vacuum casting—from design freedom to sustainability—establish composite as the superior choice for aluminum casting molds. ASUZAC ACM demonstrates this through V-Process Technology in projects like Showa Women’s University and Kogakuin Campus. Learn more at top casting aluminum manufacturer or contact us via the contact page to advance your casting requirements.