Aluminum Casting Market: Key Trends, Opportunities, and Challenges in 2025

The global aluminum casting market has been growing steadily, with projections pointing toward a significant expansion in the coming years. As industries such as automotive, aerospace, and construction continue to demand lightweight, durable materials, the aluminum casting sector is poised to witness remarkable growth. In this article, we will discuss the key opportunities and challenges in the aluminum casting market in 2025, and introduce ASUZAC-ACM, a leader in the casting aluminum industry.

Table of Contents

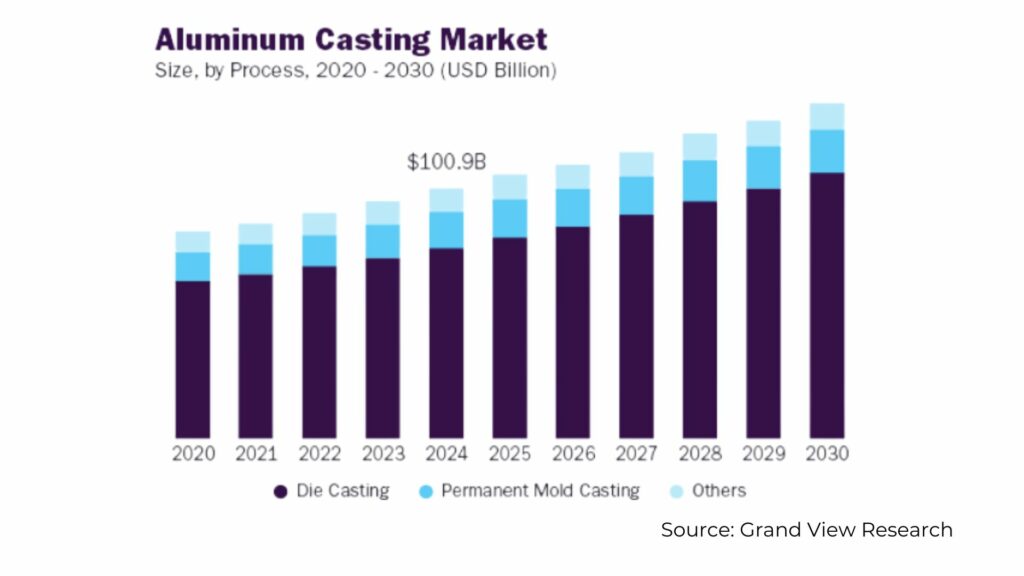

Aluminum Casting Market Size & Growth

The aluminum casting market is estimated to reach a market size of USD 100.94 billion in 2024, with a projected compound annual growth rate (CAGR) of 4.9% from 2025 to 2030, according to recent market analysis. The automotive sector, in particular, is expected to drive demand for aluminum casting due to the increased use of aluminum in lightweight vehicles. As regulatory pressures to reduce fuel emissions intensify globally, the aluminum content in lightweight vehicles is expected to rise, potentially reaching 70% in the coming years. In 2023, global sales of lightweight vehicles were approximately 15.5 million units, with this trend set to continue driving market growth (Source: Federal Reserve Bank of St. Louis).

Key Drivers of Market Growth

The demand for aluminum casting is being propelled by several key factors:

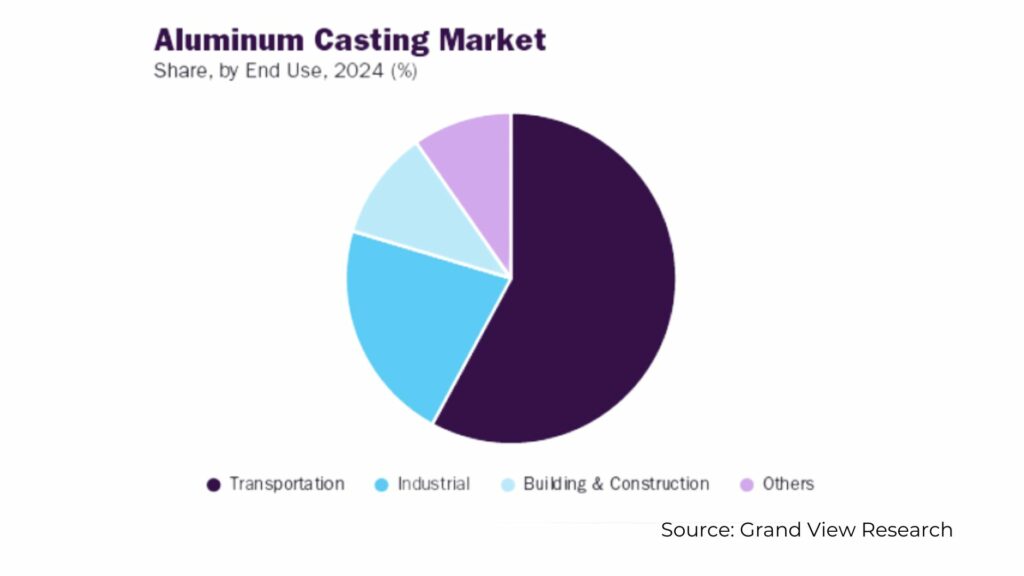

- Automotive Industry: Aluminum’s lightweight properties are increasingly sought after by the automotive sector. It helps reduce vehicle weight, leading to improved fuel efficiency and reduced emissions. As a result, aluminum castings are becoming integral in vehicle manufacturing, particularly for engine blocks, wheels, and structural components.

- Construction Sector: Aluminum casting products are gaining popularity in the construction industry, used for everything from structural components to aesthetic finishes. In particular, aluminum’s lightweight nature and resistance to corrosion make it an ideal choice for modern building materials. Aluminum casting for facades in construction involves shaping molten aluminum into various architectural forms, offering lightweight, durable, and corrosion-resistant solutions. This process allows for intricate designs and precise components, such as panels and brackets. With its aesthetic versatility and recyclability, aluminum casting not only enhances the visual appeal of buildings but also supports sustainable construction practices. The efficiency of mass production further contributes to its popularity in modern architecture.

- Defense Industry: The defense sector is expected to be another major driver for aluminum casting. The need for lightweight yet durable materials in military applications—such as aircraft, armored vehicles, and naval vessels—presents significant opportunities for aluminum casting manufacturers.

Challenges Facing the Aluminum Casting Market

Despite the promising growth, the aluminum casting market faces several challenges:

- High Equipment Costs: The initial capital required for aluminum casting equipment and technological innovations can be substantial, making it a significant barrier for small to mid-sized manufacturers looking to enter the market.

- Environmental Regulations: Stringent environmental regulations, particularly those set by the U.S. Environmental Protection Agency (EPA) and the European Environment Agency (EEA), are imposing pressure on aluminum casting processes. Manufacturers must adopt cleaner and more energy-efficient methods to meet these regulations, which can result in increased operational costs.

- Price Fluctuations: The price of aluminum has experienced volatility in recent years due to global demand, supply chain disruptions, and energy costs. These fluctuations pose a challenge for aluminum casting manufacturers, as it directly impacts production costs and profitability.

The Rise of ASUZAC-ACM: A Top Aluminum Casting Manufacturer

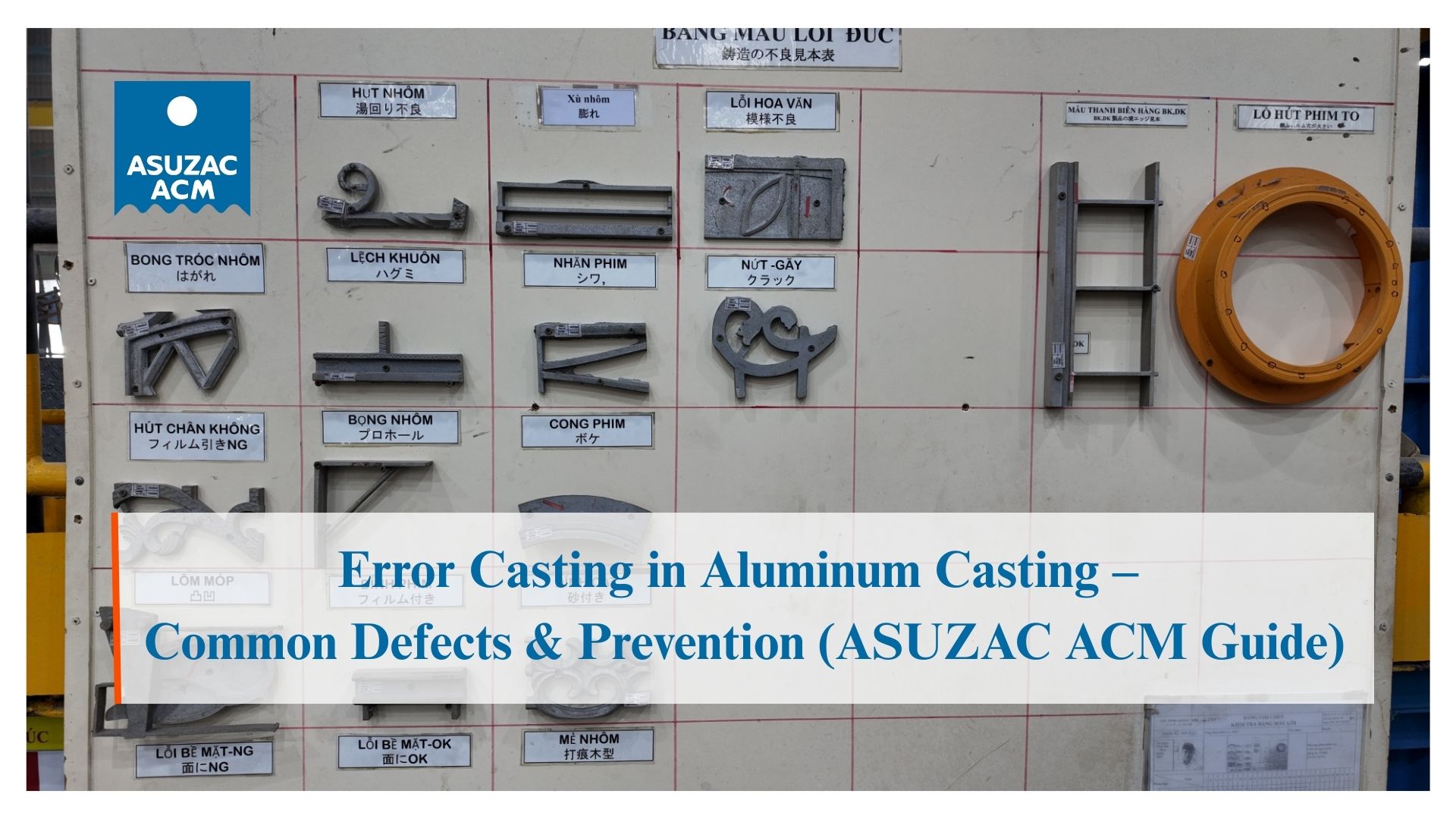

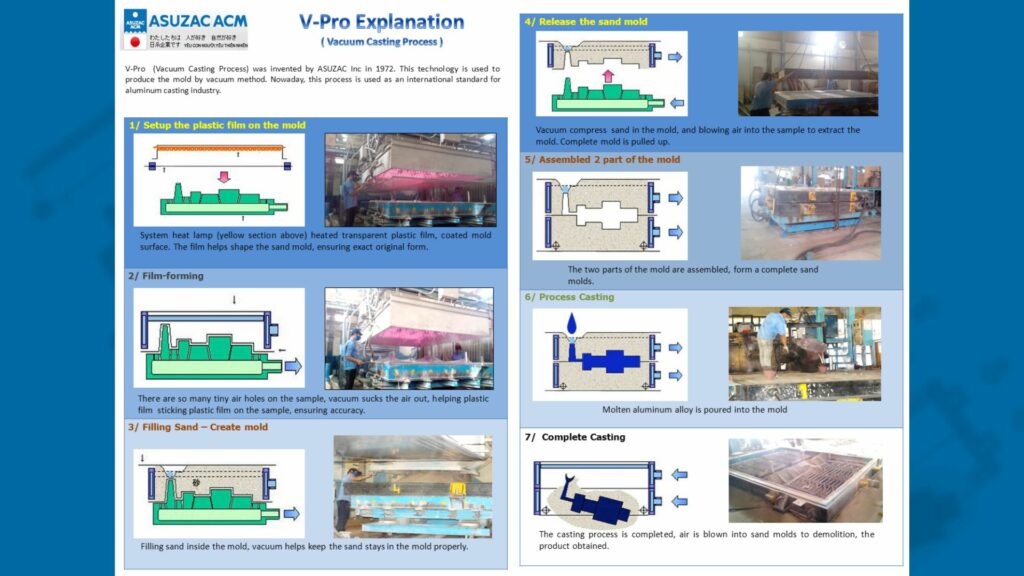

As the aluminum casting market grows, companies like ASUZAC-ACM are setting new industry standards. Founded in 1972, ASUZAC-ACM has revolutionized the industry with its patented V-Process (Vacuum Molding Process), which ensures higher-quality aluminum castings with reduced defects. This innovative process allows for smoother surfaces, precise dimensions, and enhanced mold quality, making it a preferred choice for manufacturers across multiple sectors.

ASUZAC-ACM specializes in aluminum casting for construction materials, as well as interior and exterior components, providing custom solutions that meet the unique needs of clients. Our aluminum castings are used in residential and commercial buildings, as well as infrastructure projects globally. Through our in-house teams, ASUZAC-ACM maintains control over quality, consistency, and timelines, ensuring that each product meets the highest standards.

Opportunities for ASUZAC-ACM in the Aluminum Casting Market

- Automotive Growth: As the automotive sector continues to shift toward electric and lightweight vehicles, ASUZAC-ACM’s advanced casting solutions can meet the increasing demand for durable, lightweight components.

- Global Expansion: With a solid foundation in Japan, ASUZAC-ACM has the opportunity to expand further into emerging markets in Asia Pacific, particularly in China and India, where the demand for aluminum casting is surging due to booming automotive and construction industries.

- Technological Innovation: The continued development of advanced casting techniques, such as ASUZAC-ACM’s V-Process, positions the company as a leader in high-quality aluminum casting solutions. This positions them well for future growth in sectors that require precision and high-performance materials, such as aerospace and defense.

In 2025, the aluminum casting market is expected to continue its upward trajectory, driven by the growing demand for lightweight materials in industries such as automotive, defense, and construction. However, challenges such as high equipment costs and stringent environmental regulations may impact the pace of growth. For companies like ASUZAC-ACM, which leverages innovative technologies like the V-Process, there are ample opportunities to lead the way in providing high-quality aluminum castings that meet the needs of the modern marketplace.

ASUZAC-ACM remains a top choice for aluminum casting solutions, providing customers with exceptional quality, precision, and innovation that sets them apart in the global market.