Aluminum Composite Panel Facade: ASUZAC ACM’s Precision-Cast Aluminum Casting Facade Solutions

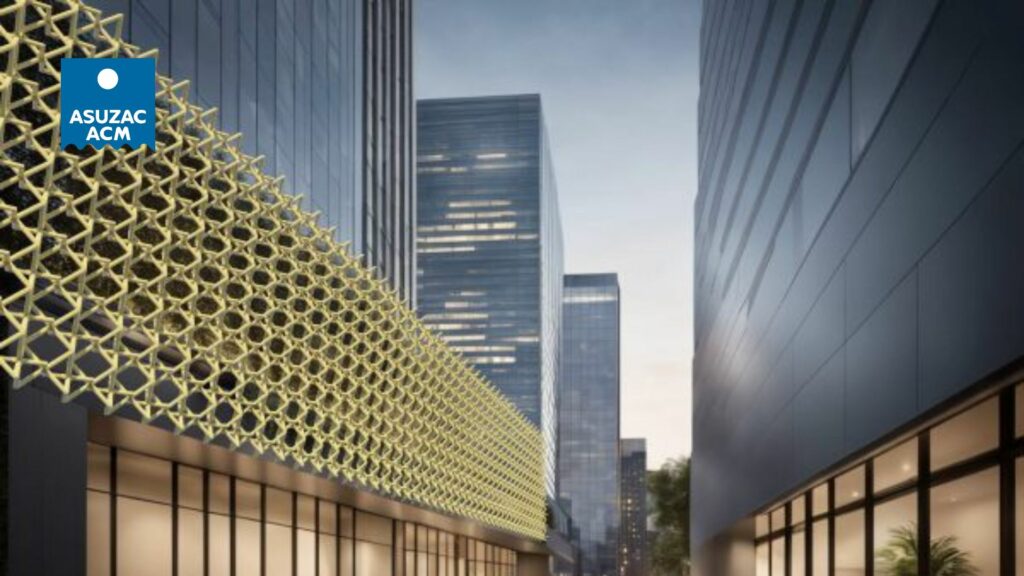

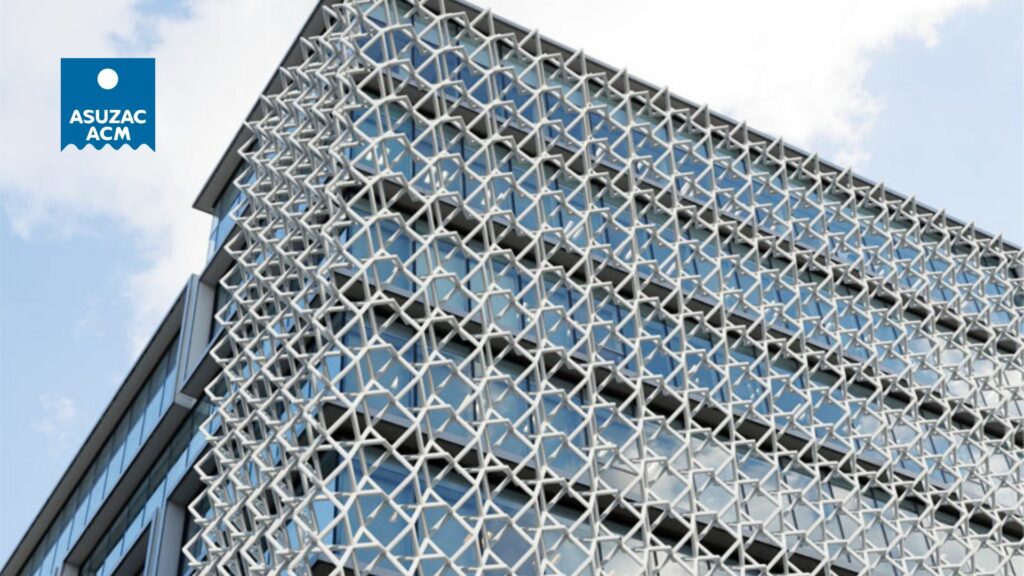

While aluminum composite panel facades are widely used, aluminum casting facades offer superior durability, design freedom, and structural integrity for premium architectural applications. As Japan’s leading aluminum casting manufacturer, ASUZAC ACM delivers high-performance aluminum casting facades that surpass traditional composite panels in longevity, customization, and aesthetic depth. Using our proprietary V-Process Technology, we produce cast aluminum panels with intricate textures, seamless finishes, and zero porosity—ideal for iconic buildings. This article compares aluminum composite panel facades with ASUZAC ACM’s cast solutions and showcases real-world projects.

Table of Contents

ASUZAC ACM: Japan’s Premier Aluminum Casting Facade Manufacturer

ASUZAC ACM, a 100% Japanese-invested subsidiary of the ASUZAC Group (established in 1946), is recognized as Japan’s foremost aluminum casting manufacturer. Since launching Vietnam operations in 2005, we’ve pioneered V-Process Technology—developed in 1972 with the Industrial Research Institute of Nagano Prefecture—to create defect-free, high-precision aluminum castings with mirror-smooth surfaces. Certified with ISO 9001, ISO 14001, and ISO 45001, we uphold excellence in quality, sustainability, and safety.

Unlike aluminum composite panel facades, our aluminum casting facades are solid cast aluminum, offering unmatched strength and design versatility. Key projects include large-scale exterior wall panels for Kogakuin University Hachioji Campus in Tokyo, Japan; custom cast facades for Thien Tue Pagoda in Vietnam; corrosion-resistant bollards and mailboxes for Bai Dinh Pagoda in Vietnam; decorative fittings for Rex Hotel in Vietnam; and intricate architectural castings for Showa Women’s University in Tokyo. These demonstrate our ability to deliver bespoke, long-lasting solutions. For inquiries, visit our contact page.

Aluminum Composite Panel Facade vs. ASUZAC ACM’s Aluminum Casting Facade

Feature | Aluminum Composite Panel Facade | ASUZAC ACM Aluminum Casting Facade |

Material Structure | Thin aluminum skins + plastic/polymer core | Solid cast aluminum (no core, no delamination risk) |

Durability | Prone to delamination, denting, fading | Monolithic strength, dent-resistant, 50+ year lifespan |

Design Flexibility | Flat or simple bends only | Intricate 3D textures, zero-draft, custom patterns via V-Process |

Weight | Lightweight (~5–8 kg/m²) | Slightly heavier but load-bearing capable |

Fire Safety | Core may be flammable (non-FR versions) | Inherently non-combustible |

Sustainability | Core not recyclable | 100% recyclable aluminum, no waste |

Maintenance | Surface scratches, edge sealing required | Powder-coated, self-cleaning, minimal upkeep |

ASUZAC ACM’s aluminum casting facade outperforms aluminum composite panel facades in premium, high-traffic, or culturally significant projects.

Benefits of Choosing ASUZAC ACM’s Aluminum Casting Facade

Our aluminum casting facades offer distinct advantages:

- Monolithic Strength: No risk of delamination—perfect for seismic zones or high-impact areas.

- Intricate 3D Detailing: V-Process Technology enables embossed logos, cultural motifs, or geometric patterns impossible with composite panels.

- Superior Weather Resistance: Solid aluminum resists UV, salt, and pollution better than coated composites.

- Eco-Friendly & Recyclable: Fully recyclable with no plastic core, supporting LEED and green building certifications.

- Thermal & Acoustic Performance: Natural mass provides better insulation than thin composite sheets.

ASUZAC ACM’s Aluminum Casting Facade Solutions

We offer tailored aluminum casting facade systems:

Institutional Building Facades

Large, seamless panels for universities and public buildings. The Kogakuin University Hachioji Campus features uniform, lightweight cast panels enhancing energy efficiency.

Cultural & Heritage Facades

Custom castings with traditional or symbolic designs. Thien Tue Pagoda integrates ornate aluminum panels that endure tropical climates.

Commercial Exterior Cladding

Durable, stylish facades for hotels and offices. Rex Hotel uses decorative cast fittings for heritage restoration.

Custom Architectural Castings

Bespoke panels with client-specific textures or branding. Contact us via our contact page for unique aluminum casting facade projects.

Real Projects: ASUZAC ACM’s Aluminum Casting Facade Excellence

ASUZAC ACM’s aluminum casting facades shine in these landmark installations:

- Kogakuin University Hachioji Campus (Tokyo, Japan): Painted cast aluminum exterior wall panels cover the campus. V-Process ensured zero porosity, consistent thickness, and lightweight installation—ideal for modern educational architecture.

- Thien Tue Pagoda (Vietnam): Custom cast aluminum facades and structural fittings blend traditional Vietnamese motifs with contemporary durability, resisting humidity and heat.

- Bai Dinh Pagoda (Vietnam): Corrosion-resistant aluminum bollards and mailboxes, cast with V-Process, maintain elegance in high-moisture temple grounds.

- Rex Hotel (Vietnam): Decorative cast aluminum facade accents revitalized the historic building, preserving heritage with modern weatherproofing.

- Showa Women’s University (Tokyo, Japan): Intricate cast aluminum architectural elements, supervised by architect Yuko Nagayama, feature complex geometries only possible through V-Process casting.

These projects prove aluminum casting facades outperform aluminum composite panel facades in longevity and design.

Why ASUZAC ACM Leads in Aluminum Casting Facade

ASUZAC ACM excels due to:

- V-Process Technology: Eliminates defects, enables complex designs.

- Solid Cast Construction: No delamination, superior strength.

- Proven Global Projects: From Kogakuin University to pagodas.

- Full Recyclability: Sustainable alternative to composite panels.

- ISO-Certified Quality: Guaranteed performance and safety.

Applications of ASUZAC ACM’s Aluminum Casting Facade

Our aluminum casting facades enhance:

- Educational Campuses: Durable, low-maintenance exteriors.

- Cultural & Religious Sites: Ornate, weatherproof designs.

- Hospitality & Heritage Buildings: Elegant, long-lasting cladding.

- Commercial Towers: Modern, high-performance envelopes.

FAQ: Aluminum Composite Panel Facade vs. Aluminum Casting Facade

Q: Why choose ASUZAC ACM over aluminum composite panel facade suppliers?

A: Our aluminum casting facades are solid, recyclable, and design-flexible using V-Process Technology.

Q: Are cast aluminum facades heavier than composite panels?

A: Slightly, but they offer structural strength and eliminate delamination risks.

Q: Is aluminum casting facade sustainable?

A: Yes—100% recyclable, no plastic core.

Q: Can I get custom designs?

A: Yes, contact us via contact page.

Q: Notable projects?

A: Kogakuin University, Thien Tue Pagoda, Rex Hotel.

Contact ASUZAC ACM for Aluminum Casting Facade

Upgrade from aluminum composite panel facade to ASUZAC ACM’s superior aluminum casting facade:

- Phone: +84-937-076-608

- Email: [email protected]

- Website: Contact Us

- Address: No 1A, St No.8, Vietnam-Singapore Industrial Park, Binh Hoa Ward, Ho Chi Minh City, Vietnam

Conclusion: Elevate with ASUZAC ACM’s Aluminum Casting Facade

While aluminum composite panel facades serve basic needs, ASUZAC ACM’s aluminum casting facades deliver unmatched durability, design freedom, and sustainability. Powered by V-Process Technology, our solutions shine in projects like Kogakuin University and Thien Tue Pagoda. Visit top casting aluminum manufacturer or contact page to transform your building envelope.