Aluminum Fins Facade: ASUZAC ACM’s Elegant & High-Performance Cast Aluminum Fins Facade Systems

An aluminum fins facade has become the defining feature of contemporary architecture, offering architects unparalleled freedom to control light, ventilation, privacy, and thermal performance while creating striking visual rhythm.

As Japan’s leading precision aluminum casting manufacturer, ASUZAC ACM crafts bespoke aluminum facade systems with intricately detailed fins that combine artistic expression with structural integrity. Using our proprietary V-Process Technology, we produce fins with flawless surfaces, complex geometries, and zero porosity—perfect for high-end commercial towers, universities, and cultural landmarks.

This comprehensive guide explores the advantages of cast aluminum fins facade, ASUZAC ACM’s design capabilities, and real-world projects that showcase our mastery.

Table of Contents

ASUZAC ACM: Japan’s Premier Aluminum Fins Facade Manufacturer

Established as a 100% Japanese-invested company under the ASUZAC Group (founded 1946), ASUZAC ACM has been recognized as Japan’s top aluminum casting specialist since beginning operations in Vietnam in 2005.

Our patented V-Process Technology—developed in 1972 with the Industrial Research Institute of Nagano Prefecture—enables us to cast large, thin-walled aluminum fins with mirror-smooth finishes and tolerances as tight as ±0.2 mm. Certified with ISO 9001, ISO 14001, and ISO 45001, we deliver sustainable, high-precision solutions worldwide.

Notable projects featuring our aluminum fins facade and related systems include:

- Kogakuin University Hachioji Campus (Tokyo) – 15,000 m² of cast aluminum facade panels and decorative fins

- Showa Women’s University 100th Anniversary Gate – Intricate cast aluminum entrance with fin-like elements

- Rihga Royal Hotel Kyoto – Custom garden bollards and architectural accents

- Takada Train Station – Structural cast aluminum elements

- Tam Chuc Pagoda – Lotus-motif cast aluminum balconies (largest pagoda complex in Southeast Asia)

For custom aluminum fins facade inquiries, visit our contact page.

Why Choose Aluminum Fins Facade from ASUZAC ACM?

Benefit | Cast Aluminum Fins (ASUZAC ACM) | Extruded Aluminum Fins (Standard) |

Design Freedom | Unlimited patterns, curves, 3D textures | Limited to linear profiles |

Surface Finish | Mirror-smooth, zero porosity | Visible die lines |

Structural Integrity | Monolithic one-piece casting | Multi-part assemblies |

Weight-to-Strength Ratio | Superior | Good |

Thermal & Acoustic Performance | Excellent (closed-cell structure) | Standard |

Corrosion Resistance | Lifetime (with PPG DURANAR®/Coraflon®) | Good |

Sustainability | 100% recyclable | 100% recyclable |

ASUZAC ACM’s Aluminum Fins Facade Collections

1. Decorative Sun-Shading Fins

Elegant horizontal or vertical fins that reduce solar heat gain while creating dynamic shadow play. Used extensively in tropical climates.

2. Parametric & 3D Fins Facade

Complex, algorithm-driven patterns impossible with extrusion. Each fin can be uniquely shaped for artistic expression.

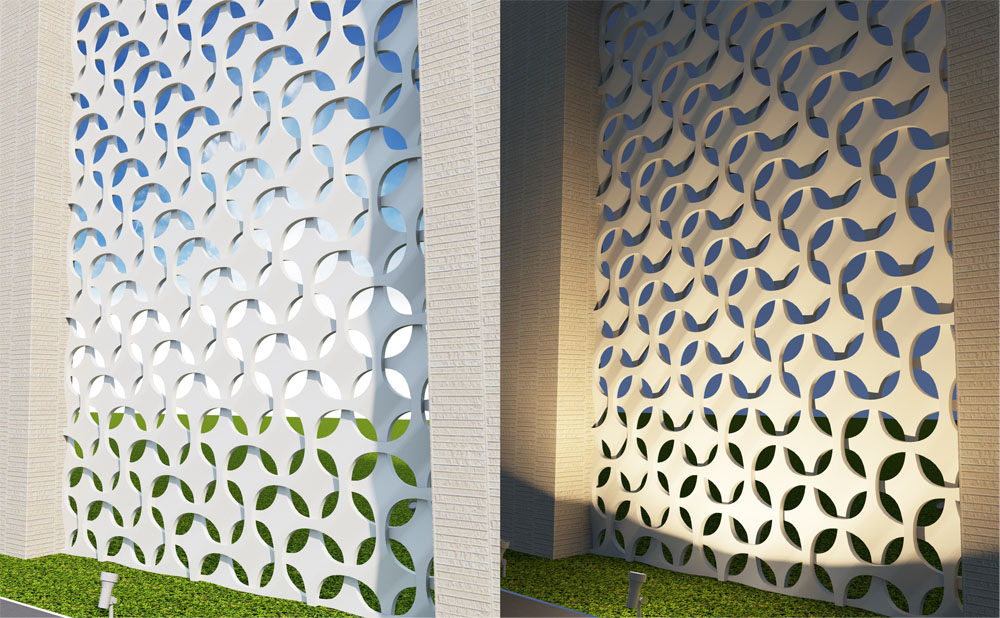

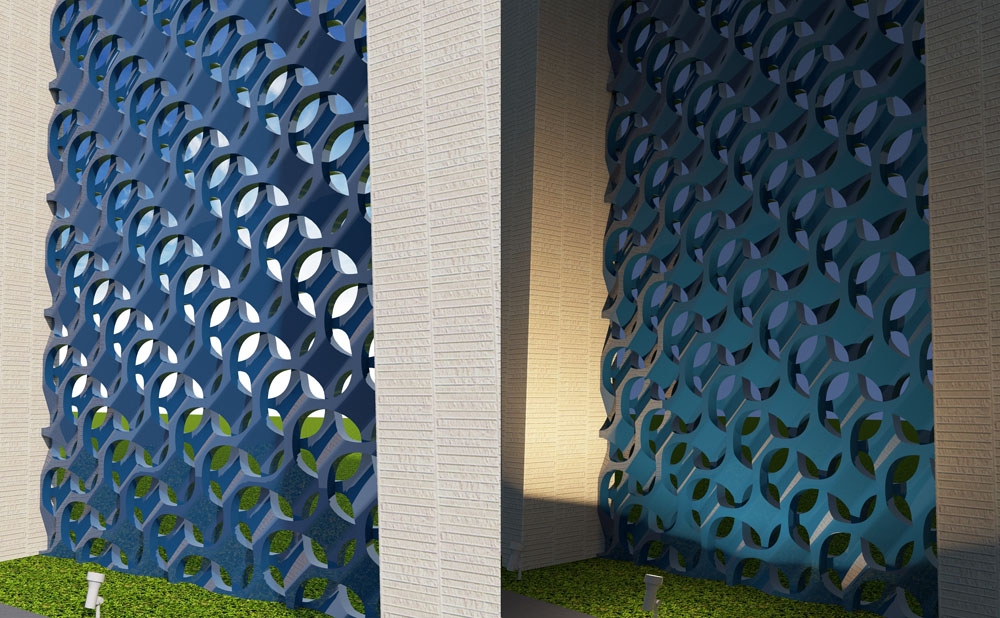

3. Perforated & Lattice Fins

Intricate cut-out designs for natural ventilation and privacy screening.

4. Integrated Lighting Fins

Fins designed with internal channels for LED integration, transforming buildings into nighttime landmarks.

5. Custom Signature Fins

Fully bespoke systems developed with architects—branding, cultural motifs, or pure artistic vision.

Technical Advantages of ASUZAC ACM’s Cast Aluminum Fins

- Thickness Flexibility: From 3 mm ultra-thin decorative fins to 50 mm+ structural elements

- Span Capability: Up to 6 meters in single-piece casting

- Coating Excellence: PPG DURANAR® liquid or Coraflon® Platinum powder (AAMA 2605 certified)

- Assembly Options: Hidden mechanical fixing, welded brackets, or fully concealed systems

- Fire Rating: Class A non-combustible (ASTM E84)

Applications of Aluminum Fins Facade

Building Type | Primary Function of Fins |

Office & Commercial Towers | Solar shading + aesthetic rhythm |

Universities & Libraries | Natural ventilation + privacy |

Hotels & Resorts | Tropical sun control + luxury appearance |

Cultural & Religious Buildings | Symbolic motifs + acoustic control |

Transportation Hubs | Wayfinding + wind deflection |

ASUZAC ACM Aluminum Fins Facade Capabilities

Feature | Specification |

Max Single Fin Length | 6,000 mm |

Min Thickness | 3 mm |

Surface Finish | Mirror smooth (V-Process) |

Coating | PPG DURANAR® / Coraflon® Platinum (AAMA 2605) |

Weight | ~2.7 kg/dm³ |

Wind Load Resistance | Up to 5.0 kPa (project-specific engineering) |

Lead Time | 8–12 weeks (design dependent) |

FAQ: Aluminum Fins Facade by ASUZAC ACM

Q: Can you replicate any extruded fin design in cast aluminum?

A: Yes—and improve it with smoother surfaces and integrated details.

Q: What is the difference in cost vs extruded fins?

A: Higher initial tooling, but lower total installed cost for complex, high-value projects.

Q: Are cast fins heavier than extruded?

A: No—optimized wall thickness achieves equal or lower weight.

Q: Can fins be curved or twisted?

A: Absolutely. V-Process enables complex 3D geometry in single pieces.

Q: What coatings do you use?

A: Only PPG DURANAR® liquid or Coraflon® Platinum powder—AAMA 2605 certified.

Contact ASUZAC ACM for Your Aluminum Fins Facade Project

Transform your vision into reality with Japan’s most advanced cast aluminum fins facade system:

- Phone: +84-937-076-608

- Email: [email protected]

- Website: Contact Us

- Address: No 1A, St No.8, Vietnam-Singapore Industrial Park, Thuận An, Bình Dương, Vietnam

Conclusion: Elevate Your Building with ASUZAC ACM’s Aluminum Fins Facade

An aluminum fins facade from ASUZAC ACM is more than sun shading—it’s a statement of precision, permanence, and beauty. Powered by V-Process Technology and protected by PPG’s finest coatings, our systems grace Japan’s most prestigious buildings and Southeast Asia’s iconic landmarks.

From the flowing waves of Kogakuin University to the sacred lotus fins of Tam Chuc Pagoda, ASUZAC ACM turns aluminum into architecture.

Visit Japan’s top casting aluminum manufacturer or contact us today to begin designing your signature aluminum fins facade.