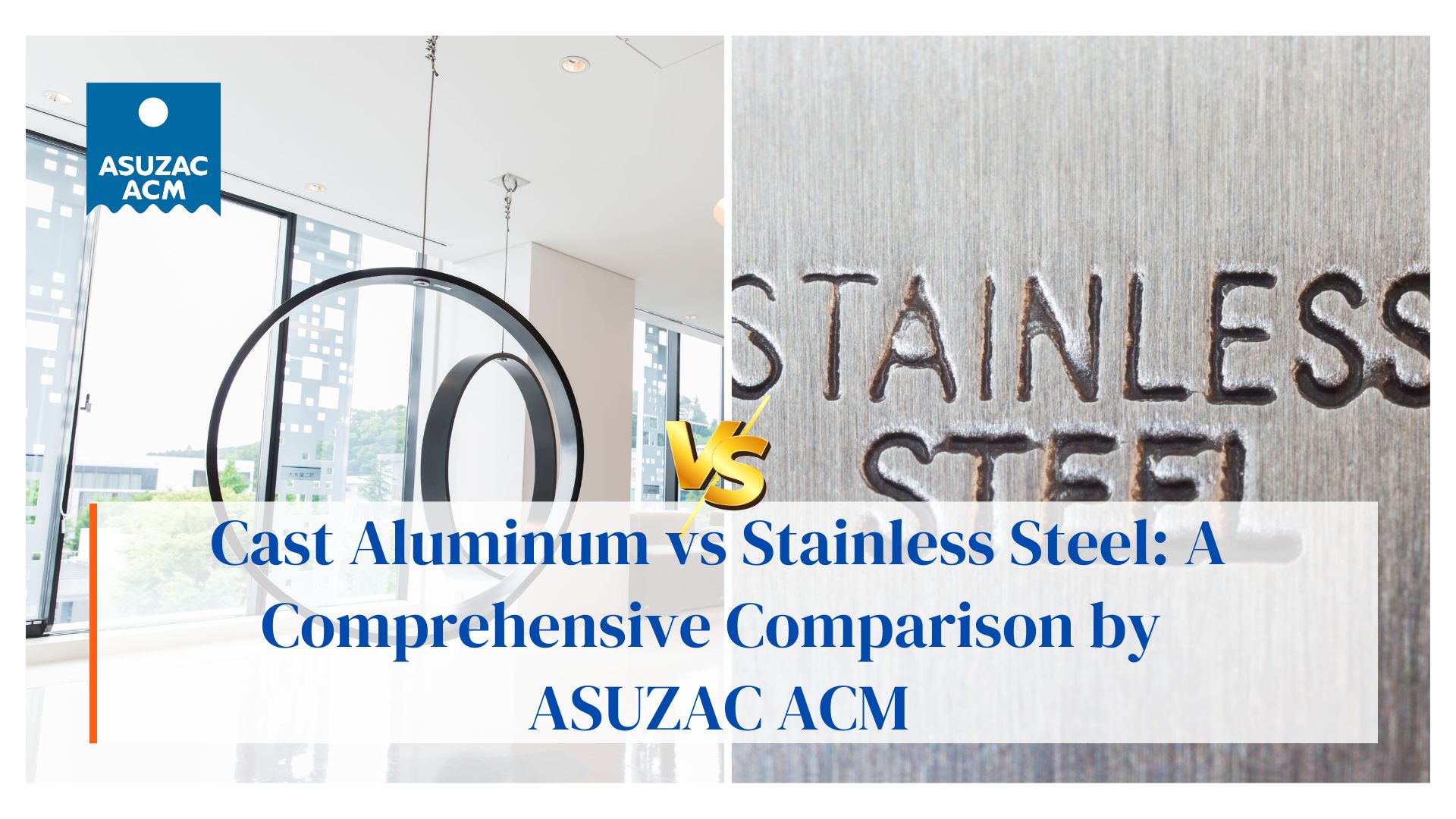

Cast Aluminum vs Stainless Steel: A Comprehensive Comparison by ASUZAC ACM

In the world of industrial manufacturing and design, material selection is critical. Two popular choices for high-performance components are cast aluminum and stainless steel. Each material offers unique benefits and is suited for specific applications. Cast aluminum is celebrated for its lightweight properties, corrosion resistance, and cost-effectiveness, while stainless steel is renowned for its exceptional strength, durability, and sleek appearance.

At ASUZAC ACM, we specialize in high-quality aluminum casting using our revolutionary V-Process technology, which enhances the performance and aesthetics of our cast aluminum parts. In this article, we will explore what cast aluminum and stainless steel are, examine their benefits, compare their properties, and explain why ASUZAC ACM stands out as a leader in aluminum casting. We’ll also provide practical insights, answer frequently asked questions, and share our contact details for more information.

Table of Contents

What is Cast Aluminum?

Cast aluminum refers to components created by melting aluminum and pouring it into a precision-engineered mold. Once the metal cools and solidifies, it takes on the exact shape of the mold, allowing for the production of complex geometries and intricate details. This process is widely used in industries such as automotive, aerospace, construction, and furniture due to the unique benefits of aluminum.

Benefits of Cast Aluminum:

- Lightweight: Aluminum is about one-third the weight of steel, making cast aluminum parts easier to handle and transport.

- High Strength-to-Weight Ratio: Despite its low density, cast aluminum exhibits remarkable strength, making it ideal for structural and high-performance applications.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents rust and corrosion, extending the lifespan of the components.

- Design Flexibility: The casting process allows for complex shapes and precise details, catering to both functional and aesthetic requirements.

- Cost-Effective: Efficient production methods and minimal waste make aluminum casting an economical choice for mass production.

- Eco-Friendly: Aluminum is fully recyclable, reducing environmental impact and supporting sustainable manufacturing practices.

What is Stainless Steel?

Stainless steel is an alloy of iron, carbon, and a minimum of 10.5% chromium, which gives it its corrosion-resistant properties. It is widely used for its strength, durability, and polished finish, making it a preferred material for applications that require both functionality and visual appeal.

Benefits of Stainless Steel:

- Exceptional Strength and Durability: Stainless steel is known for its high tensile strength, making it ideal for load-bearing applications.

- Excellent Corrosion Resistance: With the addition of chromium, stainless steel resists rust and corrosion, even in harsh environments.

- Aesthetic Appeal: Its sleek, modern look makes stainless steel popular for architectural and decorative applications.

- Low Maintenance: Stainless steel surfaces require minimal cleaning and upkeep to maintain their appearance.

- Versatility: It can be fabricated into a variety of shapes and forms, accommodating both functional and decorative uses.

- Hygienic: Stainless steel is non-porous and easy to sanitize, making it a popular choice in food processing, healthcare, and other industries requiring strict hygiene standards.

Comparing Cast Aluminum and Stainless Steel

Choosing between cast aluminum and stainless steel depends on a variety of factors, including weight, strength, cost, aesthetics, and maintenance. Below is a comparative analysis of the two materials:

Weight

- Cast Aluminum:

Lightweight and easier to handle, cast aluminum is ideal for applications where reducing overall weight is crucial, such as in automotive and aerospace industries. - Stainless Steel:

Heavier than aluminum, stainless steel offers substantial strength but can add extra weight, which may be a concern in applications where weight savings are critical.

Strength and Durability

- Cast Aluminum:

Offers an excellent strength-to-weight ratio, making it robust yet manageable. It is well-suited for applications that require a balance of strength and lightness. - Stainless Steel:

Generally stronger and more durable than aluminum, stainless steel is used in applications that demand high structural integrity and resistance to wear and tear.

Corrosion Resistance

- Cast Aluminum:

Naturally resistant to corrosion due to its oxide layer, aluminum performs exceptionally well in outdoor and humid environments. - Stainless Steel:

Highly resistant to corrosion thanks to the chromium content, stainless steel remains effective in harsh environments, including coastal areas and chemical processing plants.

Aesthetics and Design Flexibility

- Cast Aluminum:

Offers versatility in design through casting, allowing for intricate, customized shapes. Its modern appearance is ideal for contemporary design. - Stainless Steel:

Known for its polished, sleek finish, stainless steel provides a high-end, sophisticated look, which is often used in premium architectural and decorative applications.

Cost and Maintenance

- Cast Aluminum:

Generally more cost-effective due to lower material costs and easier processing. Requires minimal maintenance, making it an economical choice for many applications. - Stainless Steel:

Typically more expensive both in material and processing costs. Although durable, it may require more maintenance to preserve its polished appearance.

Why Choose ASUZAC ACM?

ASUZAC ACM is a global leader in aluminum casting, renowned for our innovative approach and commitment to quality. Our expertise is built on decades of experience and a deep-rooted commitment to precision engineering. Here’s what makes ASUZAC ACM stand out in the world of aluminum casting:

Revolutionary V-Process Technology

At the core of our manufacturing excellence is our patented V-Process casting technology. This advanced vacuum-assisted casting method ensures that our cast aluminum parts achieve:

- High Precision: Tight tolerances and intricate details that meet the most demanding specifications.

- Smooth Surface Finishes: The V-Process minimizes defects like porosity and shrinkage, resulting in a refined finish that often requires little post-casting treatment.

- Enhanced Strength: Produces components that are lightweight yet robust, perfectly suited for high-stress applications.

- Eco-Friendly Production: Reduces waste and energy consumption, aligning with our commitment to sustainable manufacturing practices.

Integrated In-House Production

Our comprehensive in-house production process—from design and mold fabrication to casting and finishing—allows us to maintain strict quality control over every component. This integrated approach ensures that our products are consistent, reliable, and tailored to meet the unique needs of our clients.

Global Expertise with a Local Presence

Headquartered in Japan and supported by a state-of-the-art manufacturing facility in Vietnam, ASUZAC ACM combines the meticulous craftsmanship of Japanese engineering with the efficiency and cost-effectiveness of modern production techniques. This global presence enables us to serve international markets effectively, offering competitive pricing and prompt, responsive support.

Commitment to Sustainability

Sustainability is a cornerstone of our operations. We utilize eco-friendly production processes, prioritize the use of recyclable materials, and continuously work to minimize waste. Our commitment to sustainability not only benefits the environment but also resonates with clients who prioritize green, responsible manufacturing practices.

Exceptional Customer Service

Our customer-centric approach ensures that we provide personalized support throughout every stage of your project—from initial consultation to final delivery. Our team of experts is dedicated to understanding your specific requirements and delivering tailored solutions that exceed expectations.

Applications of Cast Aluminum and Stainless Steel

Understanding where each material excels helps in making informed decisions:

Applications for Cast Aluminum:

- Automotive and Aerospace: Components such as engine blocks and transmission housings where weight savings are critical.

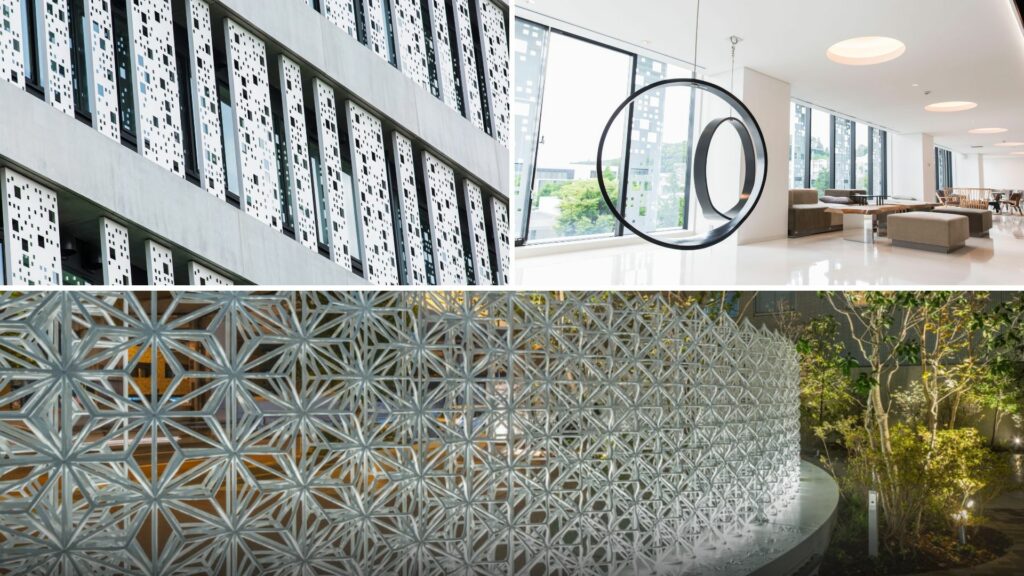

- Construction: Structural panels, decorative facades, and custom architectural elements that require a combination of strength and aesthetic appeal.

- Furniture: Outdoor and indoor aluminum furniture that benefits from a lightweight yet durable material.

- Industrial Components: Custom-designed parts for machinery and equipment that demand precision and reliability.

Applications for Stainless Steel:

- Architectural and Structural Elements: Railings, facades, and support structures where durability and a high-end appearance are essential.

- Food and Healthcare: Equipment and surfaces where hygiene and ease of cleaning are paramount.

- Marine and Chemical Industries: Applications where corrosion resistance is critical due to exposure to harsh chemicals and saltwater.

- Decorative and Artistic Installations: Elements that require a polished, modern finish and intricate detailing.

Notable Projects Showcasing Our Expertise

ASUZAC ACM’s expertise in aluminum casting is demonstrated through our involvement in several landmark projects in Japan. These projects highlight our ability to deliver high-quality components that combine strength, precision, and aesthetic appeal:

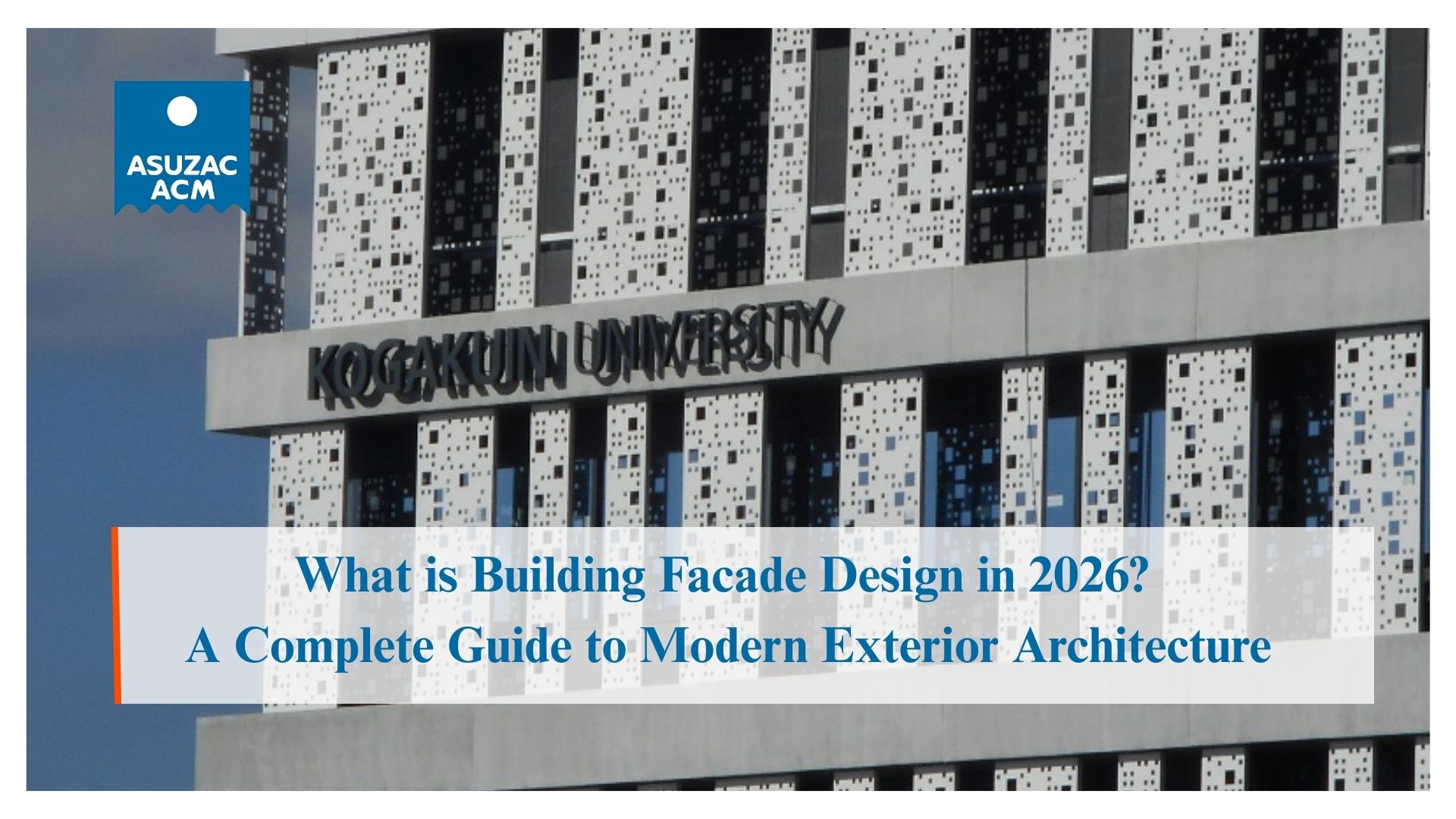

- Showa Women University, Japan:

Our cast aluminum components have been used to create architectural elements that enhance the functionality and visual appeal of the campus. - Ryukoku University Omiya Campus, Japan:

Precision-cast aluminum parts from ASUZAC ACM have contributed to the modern design and durability of this prestigious institution. - Takada Train Station, Japan:

Our products have been employed in high-traffic public infrastructure, showcasing the strength and reliability of our cast aluminum components. - Kogakuin University, Japan:

Custom-designed cast aluminum parts have been integrated into various structural and decorative elements, demonstrating our ability to meet complex design requirements.

Frequently Asked Questions (FAQs)

Q: Is cast aluminum strong?

A: Yes, cast aluminum is known for its excellent strength-to-weight ratio. Advanced casting techniques, particularly ASUZAC ACM’s V-Process, ensure that cast aluminum parts are robust and durable even in demanding applications.

Q: How does cast aluminum compare to stainless steel?

A: Cast aluminum is significantly lighter and more cost-effective than stainless steel, while still offering excellent strength and corrosion resistance. Stainless steel, however, is generally stronger and offers a more polished aesthetic but comes with higher material and processing costs.

Q: What are the benefits of aluminum casting?

A: Aluminum casting provides benefits such as durability, corrosion resistance, lightweight construction, design flexibility, cost-effectiveness, and sustainability. These advantages make it suitable for a wide range of applications, from automotive to construction and furniture.

Q: How does ASUZAC ACM ensure the quality of its cast aluminum parts?

A: We control every aspect of the production process in-house and employ our innovative V-Process technology, which minimizes defects and delivers components with exceptional precision, smooth finishes, and enhanced mechanical properties.

Q: What types of products does ASUZAC ACM offer?

A: Our product range includes structural panels, architectural elements, automotive and aerospace components, outdoor and indoor furniture, and custom-designed parts for various industrial applications. Our cast aluminum parts have been successfully used in projects such as Showa Women University, Ryukoku University Omiya Campus, Takada Train Station, and Kogakuin University.

Q: How can I contact ASUZAC ACM?

A: You can reach us at:

- Phone: +84 274 376 7136 | +84 093 707 6608

- Email: [email protected]

The debate of “cast aluminum vs stainless steel” ultimately depends on the specific requirements of your application. Cast aluminum offers an exceptional strength-to-weight ratio, cost-effectiveness, and ease of customization—qualities that are further enhanced by ASUZAC ACM’s advanced V-Process technology. While stainless steel provides superior strength and a high-end finish, its heavier weight and higher costs can be limiting factors in many applications.

At ASUZAC ACM, we specialize in delivering premium cast aluminum parts that combine the best of both worlds: lightweight durability, intricate design capabilities, and sustainable production practices. Our integrated in-house production and innovative V-Process ensure that every component we produce meets the highest quality standards. With a proven track record on landmark projects in Japan, including Showa Women University, Ryukoku University Omiya Campus, Takada Train Station, and Kogakuin University, we are proud to serve a diverse range of industries—from automotive and aerospace to construction and furniture manufacturing.

If you’re looking for high-quality aluminum casting solutions that offer unparalleled strength, performance, and design flexibility, ASUZAC ACM is your trusted partner. Contact ASUZAC ACM today to learn more about our advanced aluminum casting technologies and discover how we can help you achieve outstanding results in your next project.