A Comprehensive Guide to Aluminum Casting

Aluminum casting plays a pivotal role in modern manufacturing, offering precision, efficiency, and versatility. Whether you’re an engineer, manufacturer, or simply curious about how aluminum products are made, understanding the fundamentals of aluminum casting is essential. In this article, we’ll explore the process, applications, benefits, and types of aluminum casting.

Table of Contents

What is Aluminum Casting?

Aluminum casting is the process of creating solid aluminum products by pouring molten aluminum into a mold. After cooling and solidifying, the aluminum takes the shape of the mold, resulting in intricate, durable parts used across various industries.

This method is ideal for mass production and creating complex designs with high precision.

Types of Aluminum Casting

There are several methods of aluminum casting, each suited to specific needs and applications:

Die Casting

- Process: Molten aluminum is injected into a steel mold under high pressure.

- Applications: Automotive components, aerospace parts, and electronics.

- Advantages: High accuracy, smooth surface finish, and consistent quality.

Sand Casting

- Process: Molten aluminum is poured into a sand mold.

- Applications: Large or intricate designs like machinery parts.

- Advantages: Cost-effective for low-volume production and flexible design options.

Permanent Mold Casting

- Process: Aluminum is poured into reusable molds made of metal.

- Applications: Industrial parts, marine hardware, and pipe fittings.

- Advantages: Better mechanical properties and reduced porosity.

Investment Casting

- Process: A wax pattern is coated with a ceramic shell to form a mold, which is filled with molten aluminum.

- Applications: Precision parts for medical, aerospace, and jewelry industries.

- Advantages: Superior detail and accuracy for complex designs.

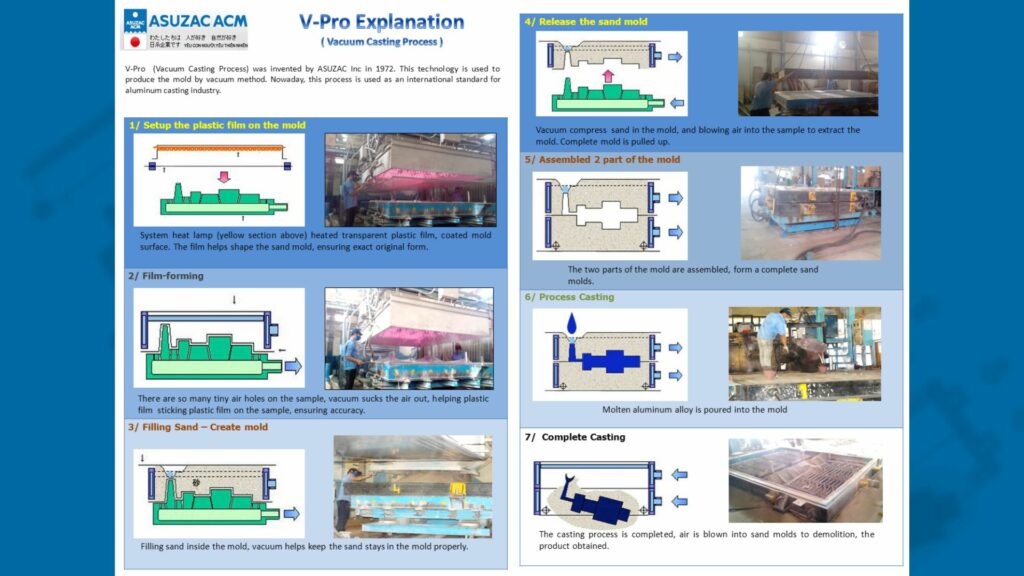

Introducing ASUZAC-ACM:

A Pioneer in V-Process Casting

ASUZAC-ACM stands out as a unique aluminum casting manufacturer specializing in the revolutionary V-process casting. The Vacuum Casting Process (V-process) is an innovative technique that doesn’t require a solidifying agent to stabilize the casting sand, allowing the sand to be reused.

Advantages of V-Process Casting:

- Eco-Friendly: Produces less industrial waste, contributing to low pollution and resource conservation.

- Energy Efficient: Reduces energy consumption compared to traditional methods.

- High Precision: Enables detailed and intricate casting with minimal defects.

ASUZAC-ACM’s V-process technology is used to produce a wide range of high-quality aluminum components, including industrial machinery parts, automotive components, and custom-designed products. With a commitment to sustainability and innovation, ASUZAC-ACM ensures exceptional performance and environmental responsibility in every product they deliver.

Benefits of Aluminum Casting

- Lightweight yet Strong: Aluminum’s lightweight nature makes it ideal for industries like automotive and aerospace without compromising on strength.

- Corrosion Resistance: Aluminum casting offers excellent resistance to rust and environmental wear.

- High Thermal and Electrical Conductivity: Suitable for electrical components and heat exchangers.

- Cost-Effective: Efficient production methods and recyclability make aluminum casting economically viable.

- Design Flexibility: Intricate shapes and complex geometries can be achieved with ease.

Applications of Aluminum Casting

Aluminum casting is prevalent in many industries due to its versatility:

- Automotive: Engine blocks, transmission cases, and wheels.

- Aerospace: Aircraft components and structural parts.

- Construction: Window frames, lighting fixtures, and hardware.

- Consumer Goods: Cookware, appliances, and sports equipment.

- Electronics: Housings, heat sinks, and connectors.

The Aluminum Casting Process: Step by Step

- Mold Preparation: The mold is prepared according to the desired shape.

- Melting Aluminum: Aluminum is heated to its melting point in a furnace.

- Pouring Molten Aluminum: The molten metal is poured into the mold.

- Cooling: The aluminum is left to cool and solidify.

- Finishing: Excess material is removed, and the casting is polished or treated as needed.

Why Choose Aluminum Casting?

Aluminum casting’s combination of strength, light weight, and adaptability makes it an indispensable part of modern manufacturing. Companies benefit from reduced production costs, enhanced product durability, and improved environmental sustainability through aluminum’s recyclability.

Aluminum casting is a cornerstone of industrial manufacturing, contributing to innovations across multiple fields. By understanding its processes, applications, and benefits, businesses can harness its full potential to create high-quality, reliable products. Whether you’re designing automotive parts or crafting detailed electronics, aluminum casting offers unmatched versatility and efficiency.

ASUZAC-ACM provides innovative solutions through its eco-friendly V-process casting technology, setting the standard for high-quality and sustainable aluminum products.

For a wide range of manufacturing capabilities, including casting and other value-added services, ASUZA-ACM is here to support all your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Contact us now!