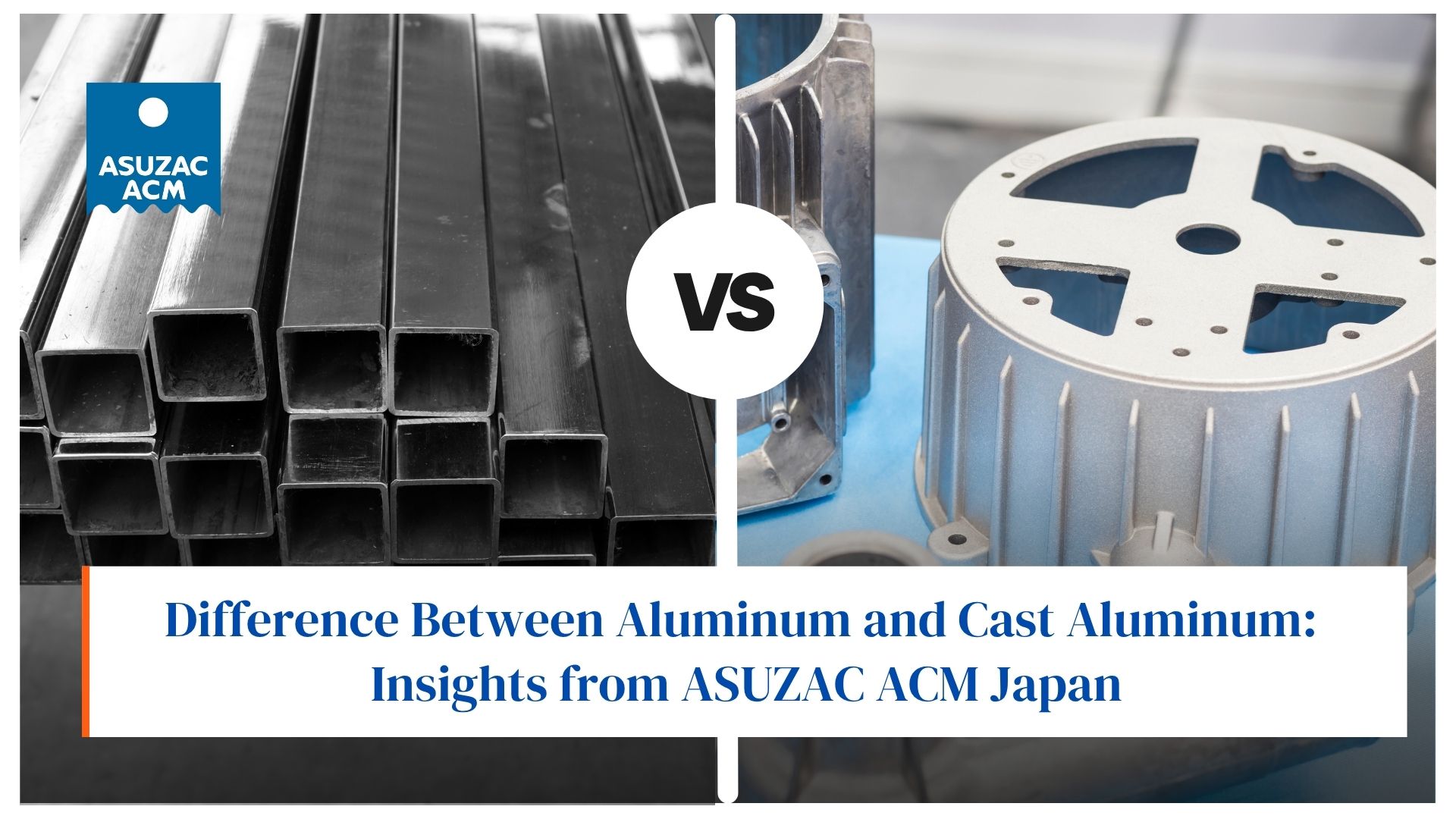

Difference Between Aluminum and Cast Aluminum: Insights from ASUZAC ACM Japan

Understanding the difference between aluminum and cast aluminum is essential for selecting the right material for your project, whether you’re designing garden furniture, architectural elements, or industrial components. While both materials share aluminum’s core benefits—lightweight strength, corrosion resistance, and versatility—they differ significantly in their manufacturing processes, properties, and applications. These distinctions impact their suitability for specific uses, such as creating durable, stylish outdoor furniture.

At ASUZAC ACM, a leading aluminum casting manufacturer from Japan, we specialize in crafting cast aluminum garden furniture within our premium table and chair product line. Using our patented V-Process Technology, we produce furniture that combines durability, aesthetic excellence, and eco-friendly design. In this article, we’ll explore the key differences between aluminum and cast aluminum, their properties, and why ASUZAC ACM’s cast aluminum furniture is ideal for garden settings.

Table of Contents

What is Aluminum?

Aluminum is a lightweight, non-ferrous metal known for its excellent corrosion resistance, high thermal and electrical conductivity, and versatility. It is typically processed through methods like rolling, extrusion, or forging to create wrought aluminum products, such as sheets, tubes, or structural components. These processes result in a uniform microstructure, enhancing strength and ductility, making wrought aluminum ideal for high-performance applications like aerospace, automotive frames, and building structures.

What is Cast Aluminum?

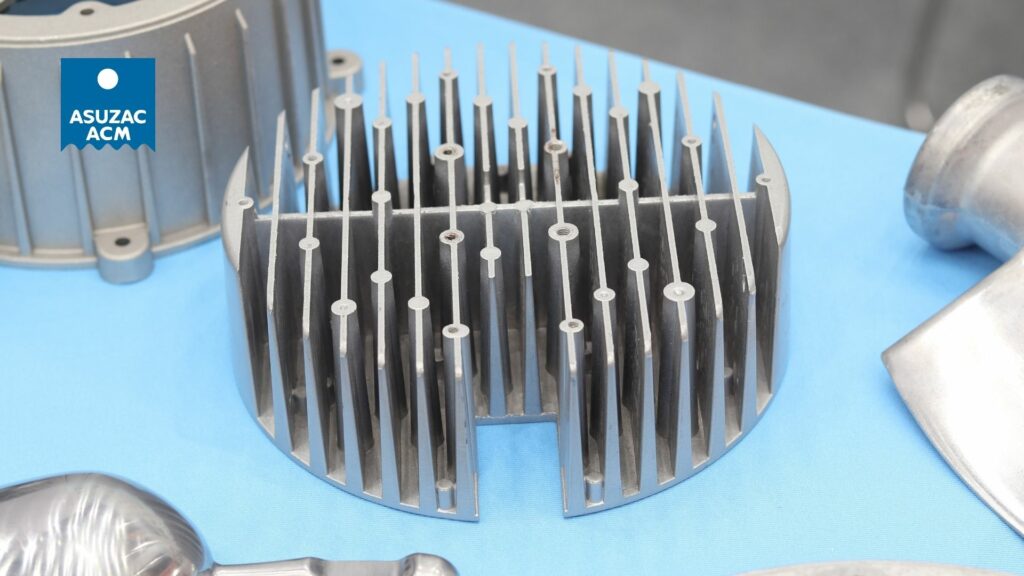

Cast aluminum refers to aluminum alloys melted and poured into molds to form specific shapes, such as intricate furniture pieces or complex components. The casting process allows for detailed designs that are challenging to achieve through other methods, making it cost-effective for producing garden furniture like tables and chairs. ASUZAC ACM’s cast aluminum garden furniture leverages this process to create durable, stylish pieces with smooth surfaces and intricate patterns, perfect for outdoor settings.

Key Differences Between Aluminum and Cast Aluminum

Manufacturing Process

- Aluminum (Wrought): Wrought aluminum is mechanically worked through rolling, extrusion, or forging, resulting in a uniform grain structure. These processes allow precise control over shape and thickness, producing strong, ductile products like sheets or beams for structural applications.

- Cast Aluminum: Cast aluminum is created by melting aluminum alloys and pouring them into molds made of sand, metal, or ceramic. The molten metal cools and solidifies into the mold’s shape, enabling complex geometries. ASUZAC ACM’s V-Process Technology enhances this process, producing furniture with minimal defects and superior finishes.

Strength and Durability

- Aluminum (Wrought): Wrought aluminum offers higher tensile strength and resistance to deformation due to its uniform microstructure. It’s ideal for high-stress applications, such as structural beams or aircraft components, where durability is critical.

- Cast Aluminum: Cast aluminum is durable but generally less strong and more brittle due to potential micro-porosity or inclusions from the casting process. For furniture, like ASUZAC ACM’s garden tables, this is less of a concern, as the focus is on design flexibility and weather resistance rather than heavy load-bearing.

Corrosion Resistance

- Aluminum (Wrought): Wrought aluminum forms a natural oxide layer that protects against corrosion, making it suitable for outdoor and marine environments. Anodizing or coatings further enhance this resistance, ensuring longevity.

- Cast Aluminum: Cast aluminum also resists corrosion but may be more susceptible to pitting due to casting imperfections. ASUZAC ACM mitigates this with powder coatings, making our cast aluminum garden furniture ideal for humid or coastal gardens.

Machinability

- Aluminum (Wrought): Wrought aluminum’s uniform grain structure makes it easier to machine, allowing precise milling, turning, or drilling for high-tolerance components. This is ideal for precision engineering.

- Cast Aluminum: Cast aluminum’s non-uniform structure can complicate machining due to varying hardness or impurities. However, ASUZAC ACM’s V-Process minimizes defects, improving machinability for furniture components when needed.

Weight Considerations

- Aluminum (Wrought): Wrought aluminum is lightweight and strong, making it ideal for weight-sensitive applications like aerospace or automotive parts. Its uniform structure optimizes weight-to-strength ratios.

- Cast Aluminum: Cast aluminum is also lightweight but may include slight variations in density due to casting. For garden furniture, this allows ASUZAC ACM to create intricate designs without excessive weight, ensuring easy rearrangement.

Cost Implications

- Aluminum (Wrought): Wrought aluminum is often more expensive due to energy-intensive processes like rolling or extrusion. Its enhanced properties justify the cost for high-performance applications.

- Cast Aluminum: Cast aluminum is more cost-effective for complex shapes, as the casting process reduces machining needs. ASUZAC ACM’s V-Process enhances efficiency, lowering costs for high-quality furniture production.

ASUZAC ACM: Leading Aluminum Casting Manufacturer from Japan

ASUZAC ACM, a Vietnam-based subsidiary of the ASUZAC Group, established in 1946, is a global leader in aluminum casting. Our V-Process Technology, developed in 1972 with the Industrial Research Institute of Nagano Prefecture, uses plastic film and vacuum pressure to create precise sand molds, producing furniture with smooth surfaces, intricate details, and minimal defects. Our expertise spans architectural and furniture products, including gates, fences, pergolas, mailboxes, and our table and chair product line.

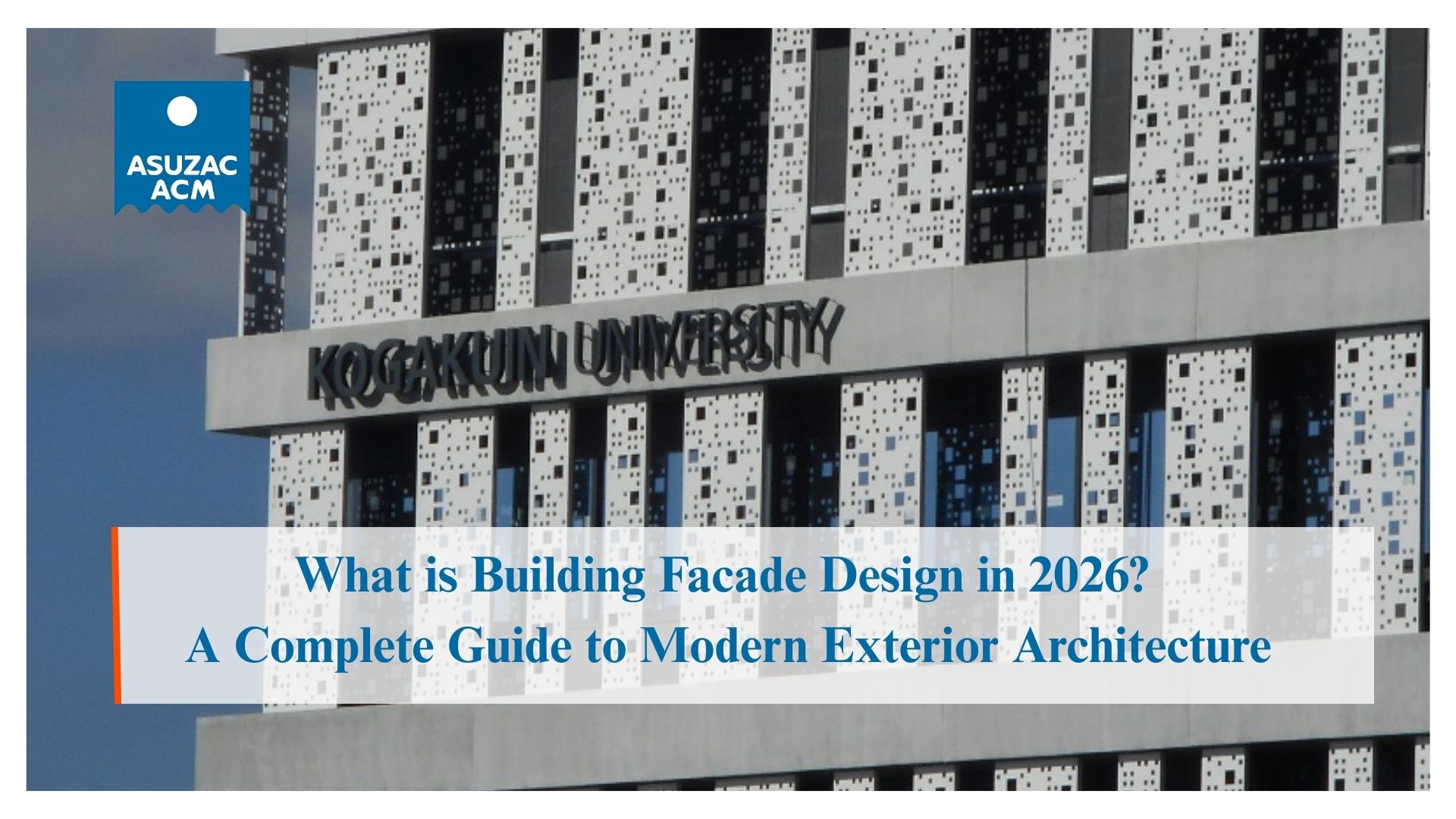

Our notable projects include supplying aluminum facades for skyscrapers like the Kogakuin Building in Japan, garden lighting bollards for the Rihga Royal Hotel in Kyoto, custom mailboxes for international apartment complexes, and pergolas for luxury resorts. Our cast aluminum garden furniture has enhanced tropical resort landscapes, urban commercial terraces, and private backyard retreats, showcasing its durability and elegance. For inquiries, visit our contact page.

Common Cast Aluminum Alloys for Furniture

ASUZAC ACM uses specific cast aluminum alloys to optimize furniture performance:

- A356 Alloy: High tensile strength and excellent casting properties, ideal for garden tables and chairs with intricate designs.

- A380 Alloy: Offers good machinability and pressure tightness, perfect for complex furniture components.

- 6061 Alloy: Provides corrosion resistance and heat treatability, suitable for durable outdoor furniture.

These alloys ensure ASUZAC ACM’s cast aluminum garden furniture balances strength, aesthetics, and weather resistance.

Comparing Aluminum and Cast Aluminum

Here’s a table summarizing the key differences between aluminum and cast aluminum for furniture applications:

Criteria | Aluminum (Wrought) | Cast Aluminum | Best For |

Manufacturing | Rolled, extruded, forged | Melted, cast in molds | Complex shapes, furniture |

Strength | Higher tensile strength | Lower, more brittle | Non-load-bearing designs |

Corrosion Resistance | Excellent, enhanced by anodizing | Good, needs coatings | Outdoor, coastal settings |

Machinability | High, uniform structure | Moderate, non-uniform | Precision vs. intricate parts |

Cost | More expensive | Cost-effective for complex shapes | Mass production, furniture |

Applications | Aerospace, structural | Furniture, decorative items | Garden furniture, decor |

ASUZAC ACM’s cast aluminum furniture, crafted with V-Process Technology, excels in design flexibility and cost-effectiveness for garden applications.

Applications of ASUZAC ACM’s Cast Aluminum Garden Furniture

Our cast aluminum garden furniture enhances various settings:

- Private Gardens: Creates stylish seating and dining areas for relaxation or entertaining in backyards or terraces.

- Commercial Spaces: Ideal for cafes, restaurants, or office courtyards, offering low-maintenance elegance.

- Hospitality Venues: Elevates luxury resorts or hotels with weather-resistant, sophisticated furniture.

- Public Areas: Enhances parks, botanical gardens, or community spaces with durable, attractive pieces.

Our furniture has been featured in tropical resort landscapes, urban rooftop gardens, and private outdoor sanctuaries, showcasing its versatility and premium quality.

Why Choose ASUZAC ACM’s Cast Aluminum Furniture?

ASUZAC ACM’s cast aluminum furniture offers distinct advantages:

- Precision Craftsmanship: V-Process Technology ensures flawless surfaces and intricate designs.

- Rust-Free Durability: Powder-coated finishes enhance corrosion resistance for outdoor longevity.

- Customization Options: Offers diverse styles, colors, and cushion choices for personalized garden aesthetics.

- Eco-Friendly Materials: Uses 100% recyclable aluminum, supporting sustainable design.

- Global Expertise: Trusted for projects like the Kogakuin Building, Rihga Royal Hotel, and Thien Tue Pagoda.

FAQ: Difference Between Aluminum and Cast Aluminum

Q: What is the main difference between aluminum and cast aluminum?

A: Wrought aluminum is mechanically worked (rolled, extruded) for high strength, while cast aluminum is molded for complex shapes, ideal for ASUZAC ACM’s cast aluminum garden furniture.

Q: Is cast aluminum better for garden furniture than wrought aluminum?

A: Cast aluminum is more cost-effective and versatile for intricate furniture designs, while wrought aluminum is stronger but less flexible for complex shapes.

Q: How durable is ASUZAC ACM’s cast aluminum furniture?

A: Our furniture is rust-free, powder-coated, and built for outdoor durability, perfect for gardens. Contact us via our contact page for details.

Q: Can cast aluminum furniture be customized?

A: Yes, ASUZAC ACM offers customizable designs, colors, and finishes for our table and chair product line.

Q: Is ASUZAC ACM’s furniture eco-friendly?

A: Yes, our furniture uses 100% recyclable aluminum, and our V-Process minimizes waste, supporting sustainability.

Contact ASUZAC ACM for Your Cast Aluminum Furniture Needs

Ready to enhance your garden with our cast aluminum garden furniture? Our team at ASUZAC ACM is here to assist:

- Phone: +84 274 376 7136 | +84 093 707 6608

- Email: [email protected]

- Website: Contact Us

Conclusion: Choose ASUZAC ACM for Premium Cast Aluminum Furniture

Understanding the difference between aluminum and cast aluminum helps you select the right material for your project. Cast aluminum, with its design flexibility and cost-effectiveness, is ideal for garden furniture, as showcased in ASUZAC ACM’s table and chair product line. Crafted with V-Process Technology, our furniture offers rust-free durability, elegant designs, and eco-friendly performance. As a leading aluminum casting manufacturer from Japan, our global projects, from the Rihga Royal Hotel to Thien Tue Pagoda, demonstrate our expertise in creating high-quality, long-lasting products.

Visit top casting aluminum manufacturer to explore our capabilities or reach out via our contact page to bring our cast aluminum furniture to your next project today.