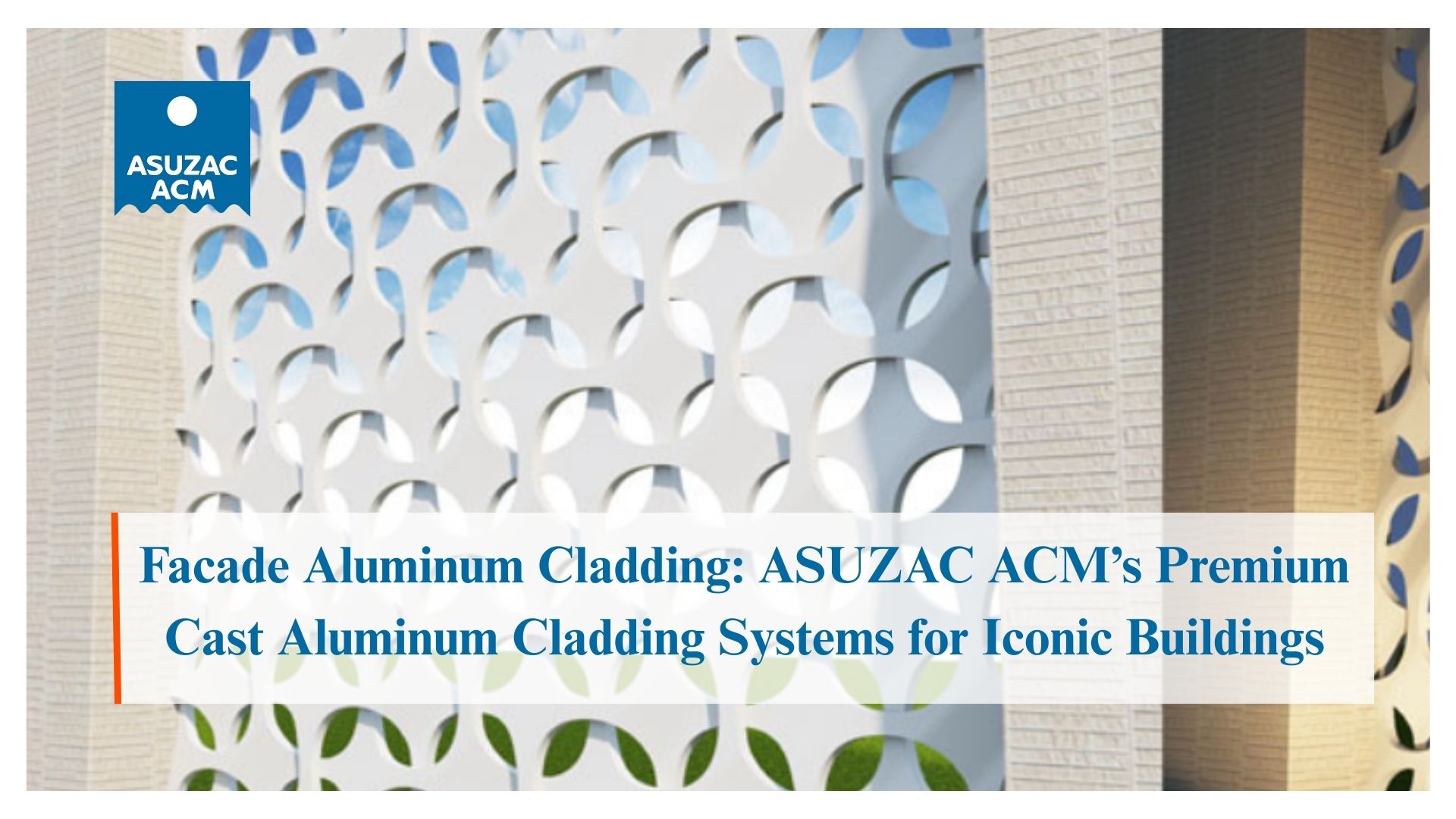

Facade Aluminum Cladding: ASUZAC ACM’s Premium Cast Aluminum Cladding Systems for Iconic Buildings

Facade aluminum cladding has become the material of choice for architects who demand permanence, beauty, and total design freedom. While extruded or rolled-sheet cladding dominates the market, true landmark buildings require something more: precision-cast aluminum cladding that allows complex 3D textures, large monolithic panels, and flawless finishes impossible with conventional methods.

As Japan’s leading aluminum casting manufacturer, ASUZAC ACM specializes in high-end aluminum facade cladding produced using our exclusive V-Process Technology. This vacuum-molding process delivers mirror-smooth, porosity-free surfaces and enables panel sizes up to 3000 × 1500 mm in a single casting—perfect for seamless, monumental facades.

This comprehensive guide explores why top architects specify ASUZAC ACM cast aluminum cladding for their most prestigious projects worldwide.

Table of Contents

ASUZAC ACM: Japan’s Premier Facade Aluminum Cladding Specialist

Since 2005, ASUZAC ACM – a 100% Japanese-invested company under the historic ASUZAC Group (est. 1946) – has been recognized as Japan’s top precision aluminum casting expert. Our patented V-Process Technology produces facade panels with surface quality and dimensional accuracy unmatched in the industry.

All cladding systems are coated with PPG DURANAR® liquid or Coraflon® Platinum powder (AAMA 2605 certified) and backed by 20–30-year warranties.

Signature projects featuring ASUZAC ACM facade aluminum cladding include:

- Kogakuin University Hachioji Campus (Tokyo) – 15,000 m² of textured cast aluminum cladding panels

- Showa Women’s University 100th Anniversary Project – Sculptural cast aluminum entrance cladding

- Rihga Royal Hotel Kyoto – Custom decorative facade cladding with traditional Japanese motifs

- Multiple 5-star coastal resorts (Vietnam, Thailand, Indonesia) – Salt-resistant cast cladding systems

- Tam Chuc Pagoda – Lotus-pattern cast aluminum cladding and balconies (largest Buddhist complex in Southeast Asia)

Ready to specify the finest Japanese cast aluminum cladding? Reach us through our contact page.

Why Architects Choose ASUZAC ACM Cast Aluminum Cladding Over Extruded/Rolled Systems

Advantage | ASUZAC ACM Cast Cladding | Extruded / Composite Panel Cladding |

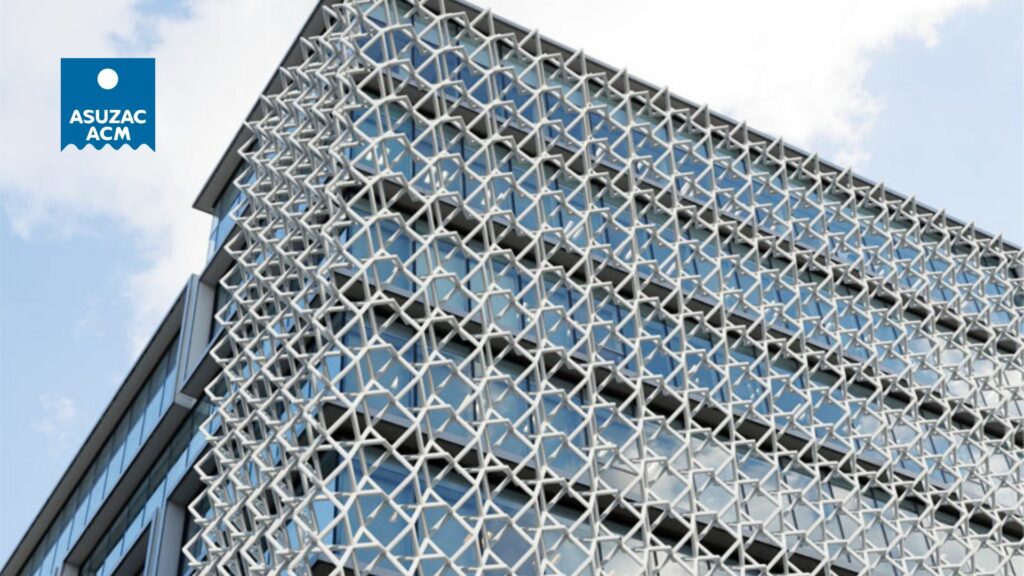

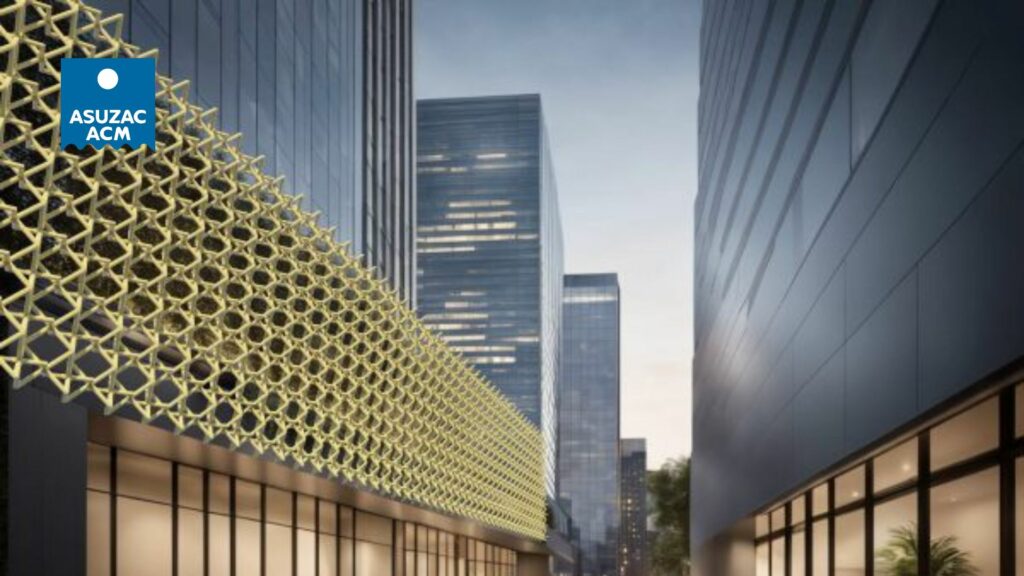

Design Freedom | Unlimited 3D textures, curves, undercuts | Flat or simple bends only |

Panel Size | Up to 3000 × 1500 mm monolithic | Limited by extrusion width |

Surface Finish | Mirror smooth, zero porosity | Visible grain or roller marks |

Joint Appearance | Minimal or seamless (large panels) | Visible joints every 1–1.5 m |

Structural Performance | One-piece = higher rigidity | Multi-layer = potential delamination |

Thermal Expansion Joints | Fewer required | More frequent |

Coating Durability | Perfect adhesion on V-Process surface | Standard |

Fire Rating | Class A non-combustible | Depends on core material |

ASUZAC ACM Facade Aluminum Cladding Collections

- Textured Wave Cladding – Organic flowing patterns for dynamic light reflection

- Geometric Relief Cladding – Hexagonal, triangular, or parametric 3D surfaces

- Cultural & Heritage Series – Cherry blossom, lotus, dragon-scale, or temple-inspired textures

- Perforated Cladding Panels – Integrated mesh patterns for ventilation and privacy

- Anodized-Look Cast Cladding – Coraflon® Platinum powder in true matte bronze, champagne, black

- Monolithic Large-Format Panels – Up to 4.5 m² per panel with hidden fixing systems

Benefits of Specifying ASUZAC ACM Facade Aluminum Cladding

- Seamless Aesthetics – Large panels = fewer joints = cleaner look

- Lifetime Durability – Zero porosity + AAMA 2605 coating = decades without chalking or fading

- Sustainability – 100% recyclable, low-VOC or zero-VOC powder options

- Fast Installation – Pre-engineered hidden fixing systems reduce on-site labor

- Design Support – Full BIM/Revit families and 3D modeling services included

FAQ: Facade Aluminum Cladding by ASUZAC ACM

Q: How does cast cladding compare in cost to ACM panels?

A: Higher initial material cost, but lower total installed cost on premium projects due to fewer panels and joints.

Q: Can you match existing extruded cladding colors?

A: Yes—PPG custom color matching ensures perfect harmony.

Q: What fixing systems do you recommend?

A: Concealed undercut anchors, cassette systems, or structural silicone bonding.

Q: Are mock-ups provided?

A: Full-size physical mock-ups available for all projects over 1,000 m².

Contact ASUZAC ACM for Your Next Facade Aluminum Cladding Project

Elevate your building with Japan’s finest cast aluminum cladding:

- Phone: +84-937-076-608

- Email: [email protected]

- Request quotation & samples: Contact Us

- Factory: Lot 1A, Street 8, VSIP II-A, Binh Duong, Vietnam

Conclusion: Define Your Legacy with ASUZAC ACM Facade Aluminum Cladding

When only the very best will do—when your building deserves to be remembered for generations—choose facade aluminum cladding from ASUZAC ACM.

Powered by revolutionary V-Process Technology and protected by PPG’s legendary coatings, our cast aluminum cladding systems have already transformed universities, hotels, and sacred sites across Asia.

Your iconic facade starts here. Contact ASUZAC ACM today.