Facade Design Pattern: Modern Aluminum Facade Ideas & Trends in 2026

Facade design pattern is one of the most powerful tools architects and developers use in 2026 to define a building’s personality, control its environmental performance, and create long-term visual and economic value.

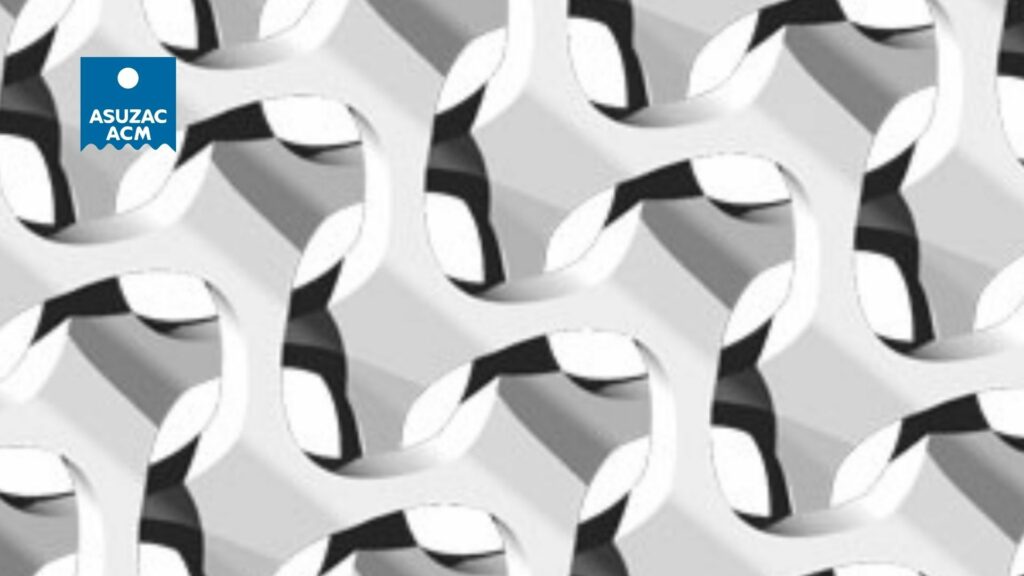

Gone are the days when a facade was merely “cladding.” Today, the right facade pattern is a deliberate combination of geometry, texture, rhythm, light-shadow play, cultural symbolism, and climate-responsive functionality — often executed in aluminum facade systems for their unmatched versatility, durability, and recyclability.

This 2026 guide explains:

- what facade design pattern really means in contemporary architecture

- the main categories of patterns used today

- how aluminum (especially cast aluminum) enables the most sophisticated and durable patterns

- major facade pattern trends in 2026–2030

- real-world examples of iconic aluminum facade patterns delivered by ASUZAC ACM, Japan’s leading precision-cast aluminum specialist

Table of Contents

What is a Facade Design Pattern?

A facade design pattern refers to the intentional repetition, variation, scale, rhythm, texture, and depth applied to a building’s exterior surface to achieve aesthetic, functional, and performance goals.

Common objectives include:

- creating visual rhythm and hierarchy

- controlling solar heat gain, daylight, and glare

- enabling natural ventilation and rain-screen performance

- expressing cultural identity or brand language

- reducing perceived scale of large buildings

- generating dynamic light-shadow effects throughout the day

In 2026, facade patterns are no longer static — many are adaptive (responsive louvers, kinetic elements) or data-driven (parametric algorithms that optimize for sun path, wind, views, and local climate).

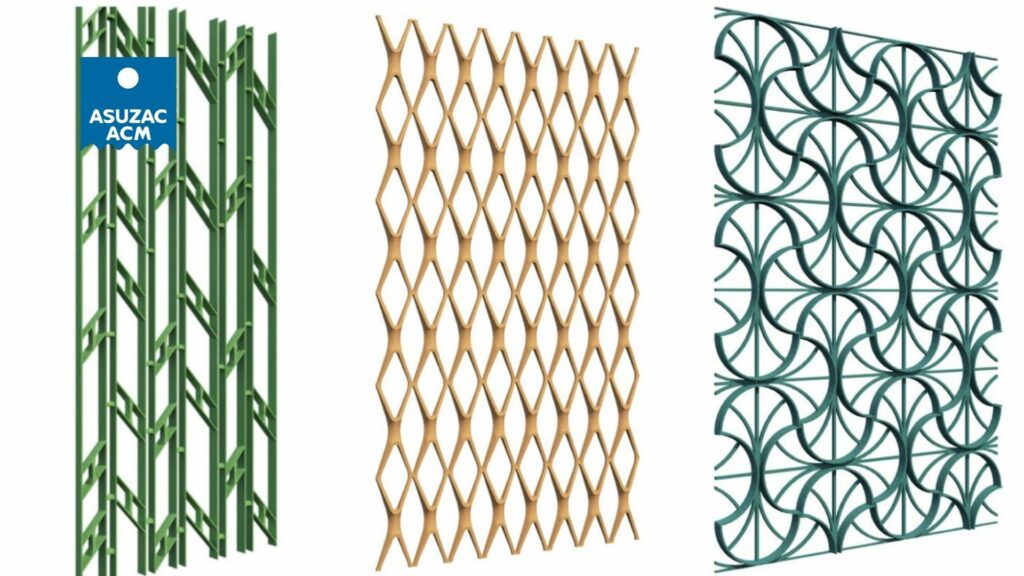

Main Categories of Facade Design Patterns in 2026

- Geometric / Grid-Based

- Regular repetition (square, hexagonal, triangular grids)

- Often used in office towers for clean, modern identity

- Parametric / Algorithmic

- Non-uniform variation in size, angle, depth or perforation

- Creates organic, flowing effects — very popular in 2026

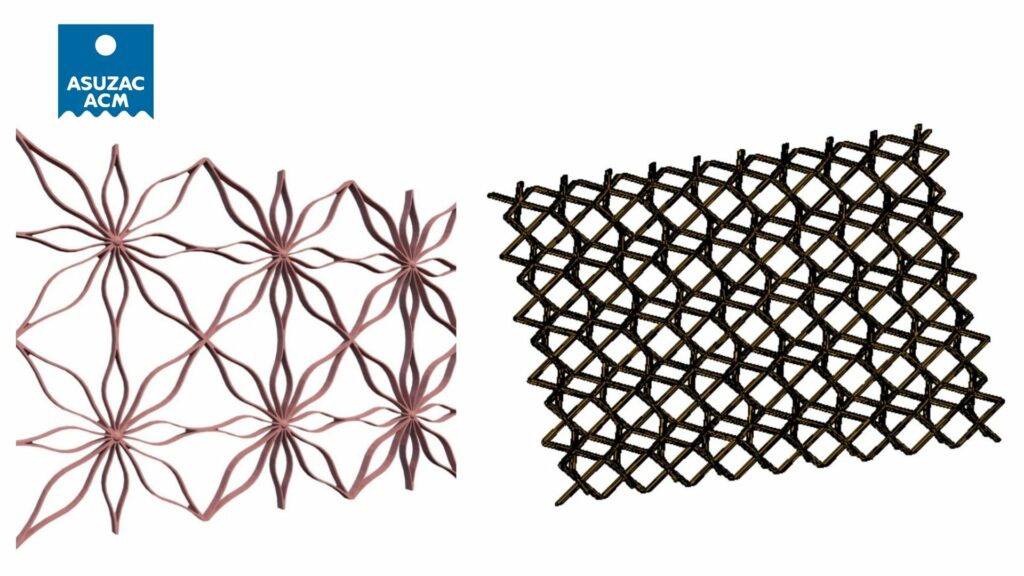

- Perforated / Screen Patterns

- Holes, slots, or cut-outs for light filtration, ventilation, privacy

- Mashrabiya-inspired or fully digital gradients

- Textured / Relief Patterns

- 3D depth (waves, ripples, folds, embossed motifs)

- Cast aluminum excels here — deepest relief possible

- Cultural / Symbolic Patterns

- Local heritage motifs (lotus, bamboo, arabesque, Vietnamese bronze drum patterns) cast directly into metal

- Bioclimatic / Responsive Patterns

- Fixed or movable louvers, fins, or shutters that optimize shading and airflow

Aluminum — especially cast aluminum facade systems — is the material of choice when architects want deep relief, large seamless panels, and complex patterns that extruded or composite systems simply cannot achieve.

ASUZAC ACM – Japan’s Leading Cast Aluminum Facade Specialist

ASUZAC ACM is widely regarded as Japan’s foremost expert in precision-cast aluminum architectural components and facade systems.

A 100% Japanese-owned company under the ASUZAC Group (founded 1946), ASUZAC ACM has operated its advanced Vietnam factory since 2005. The company’s signature V-Process Technology — a vacuum-assisted casting method — produces panels with:

- mirror-smooth surfaces

- zero internal porosity

- exceptional dimensional accuracy (±0.2 mm tolerance achievable)

- ability to create large monolithic panels and complex 3D reliefs in single pieces

All facade products are finished exclusively with AAMA 2605-compliant premium PPG coatings — the global gold standard for architectural aluminum longevity — ensuring color fade ≤5 ΔE, chalk rating ≤8, and film integrity after 10 years of intense South Florida-equivalent exposure.

PPG Premium Coating Systems Used by ASUZAC ACM

ASUZAC ACM applies only PPG’s top-tier systems:

- PPG DURANAR® Liquid 70% PVDF — unmatched color accuracy, deep tones, and proven >50-year real-world data → PPG Liquid Coatings for Architectural Aluminum

- PPG Coraflon® Platinum FEVE Powder — single-coat efficiency, true anodized looks, 100% reclaimable, zero VOCs/HAPS/BPA/TGIC/PFOA → PPG Coraflon Platinum FEVE Powder Coatings

- Liquid vs Powder Comparison — helps architects choose the optimal system → PPG Liquid vs Powder Coatings Comparison

By pairing V-Process casting (perfect substrate) with PPG AAMA 2605 coatings (ultimate protection), ASUZAC ACM guarantees facades that remain vibrant and maintenance-free for 30+ years — even in Vietnam’s aggressive tropical climate.

Major Facade Design Pattern Trends in 2026–2030

- Bioclimatic & Adaptive Patterns — fixed or movable louvers/perforations responding to sun path

- Ultra-Large Monolithic Panels — fewer joints, cleaner rhythm

- Parametric & Generative Patterns — algorithm-driven 3D reliefs for light-shadow dynamics

- Cultural & Identity Patterns — local motifs (lotus, bamboo, dragon-scale) cast directly into metal

- Hybrid Metal + Green — aluminum cast elements combined with vertical gardens, PV glass

- Circular & Low-Carbon Patterns — 100% recyclable aluminum + low-embodied-carbon finishes

ASUZAC ACM’s cast aluminum systems excel particularly in trends #2, #3, and #4.

Contact ASUZAC ACM – Your Trusted Partner for Advanced Facade Design Patterns

Ready to bring your next facade pattern vision to life with Japan’s most advanced cast aluminum technology?

- Phone: +84-937-076-608

- Email: [email protected]

- Website: Contact Us

- Address: No. 1A, Road No. 8, Vietnam – Singapore Industrial Park, Binh Hoa Ward, Ho Chi Minh City

Facade Patterns Define the Future

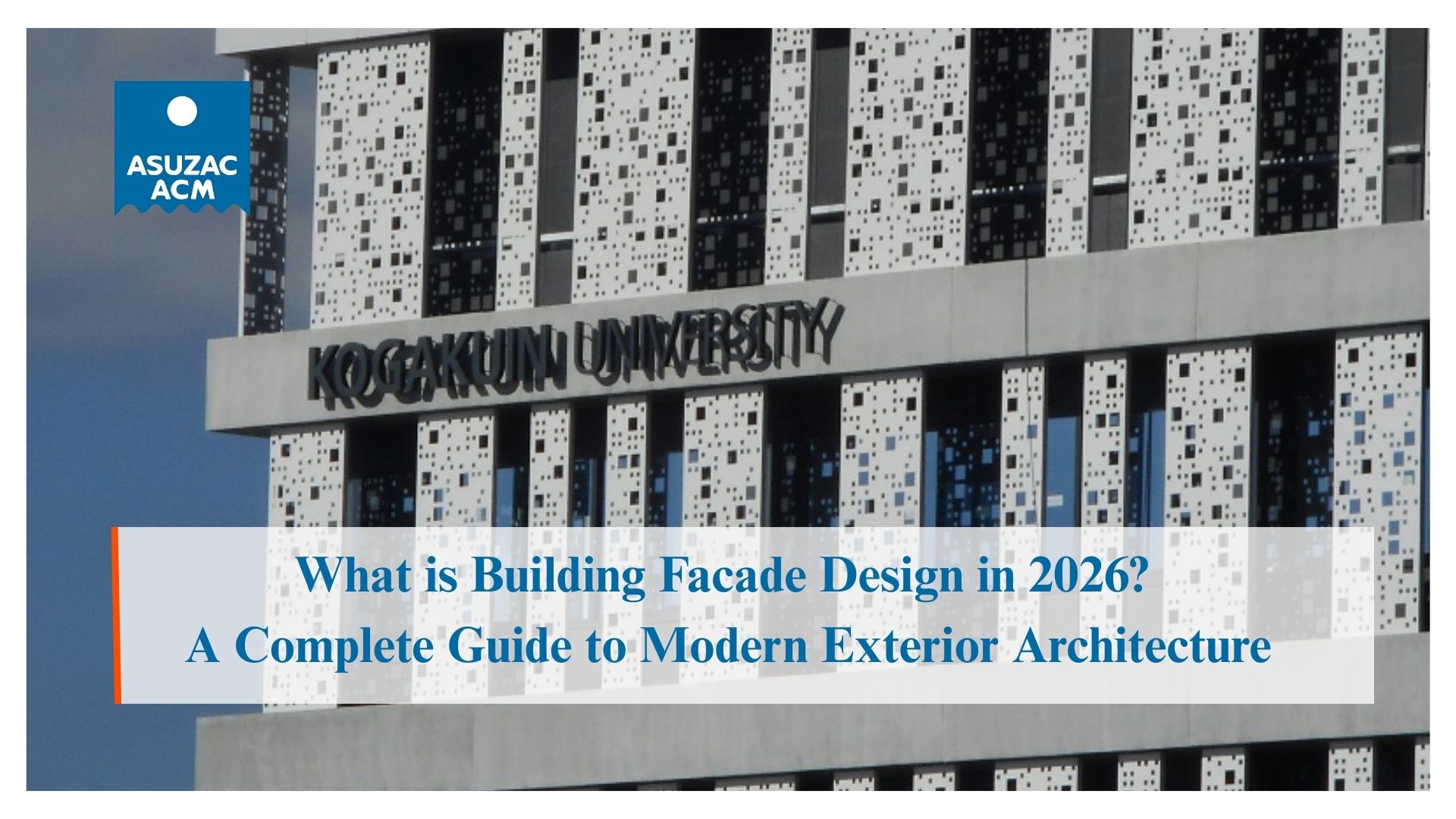

What is building facade design in 2026? It is performance art, environmental intelligence, cultural expression, and legacy creation — all engineered into one beautiful, functional system.

Companies like ASUZAC ACM — proven on landmark projects such as Ho Chi Minh City Metro Line 1 and Kogakuin University — are helping architects worldwide turn bold facade design patterns into built reality with cast aluminum systems that are stunning, sustainable, and built to last.