How to Paint Aluminum Furniture: A Comprehensive Guide by ASUZAC ACM

Aluminum furniture has emerged as a popular choice in modern design due to its lightweight durability, sleek aesthetics, and resistance to weather. Whether you’re refreshing your patio set or upgrading your indoor décor, aluminum furniture offers a versatile and sustainable option that lasts. However, over time, even the most robust aluminum furniture may need a touch-up or complete repaint to restore its beauty.

In this comprehensive guide, we will explore everything you need to know about painting aluminum furniture—from understanding its benefits to step-by-step instructions on how to prepare and finish your piece for a professional look. We’ll also highlight ASUZAC ACM’s role as a leader in the aluminum casting industry and explain how our cutting-edge V-Process technology delivers superior aluminum components that are easier to maintain and repaint. This article provides all the necessary information to help you achieve a vibrant, durable finish on your aluminum furniture.

Table of Contents

What is Aluminum Furniture?

Aluminum furniture is crafted from aluminum or its alloys and is renowned for its lightweight nature, durability, and resistance to corrosion. Unlike traditional materials such as wood or wrought iron, aluminum offers several distinct advantages:

- Lightweight & Portable: Easy to move and rearrange, ideal for both indoor and outdoor spaces.

- Corrosion Resistance: Naturally resistant to rust and weathering, ensuring long-term durability.

- Low Maintenance: Requires minimal upkeep compared to wood, which may need frequent sealing or painting.

- Modern Aesthetic: Features sleek, minimalist designs that suit contemporary décor.

- Eco-Friendly: Aluminum is fully recyclable, making it a sustainable choice for environmentally conscious consumers.

Benefits of Cast Aluminum Parts

Cast aluminum parts are a critical element in the manufacturing of high-quality furniture. Here are some of the main benefits:

- Superior Strength-to-Weight Ratio: Aluminum cast parts provide robust performance without the bulk, which is essential for both functional and decorative applications.

- Complex and Intricate Designs: The casting process allows for detailed designs that can be customized to meet specific aesthetic and performance requirements.

- Cost-Effectiveness: Aluminum casting is an efficient manufacturing process that minimizes waste and reduces the need for extensive machining.

- Enhanced Durability: Cast aluminum resists corrosion and weathering, ensuring that furniture maintains its appearance and structural integrity over time.

- Sustainability: With aluminum being 100% recyclable, the environmental impact of production and end-of-life disposal is significantly reduced.

How to Paint Aluminum Furniture: Step-by-Step Guide

Achieving a professional-looking finish on aluminum furniture requires proper preparation, the right materials, and careful application. Here’s how to do it:

1. Gather Your Materials

Before you start, make sure you have the following:

- Mild detergent or dish soap

- Warm water

- A bucket

- A soft-bristled brush or sponge

- Fine-grit sandpaper (220-grit)

- A tack cloth or microfiber cloth

- A high-quality primer formulated for aluminum

- Acrylic or enamel paint suitable for metal surfaces

- A clear protective topcoat (optional)

- Painter’s tape and drop cloths

2. Clean the Surface Thoroughly

Start by cleaning your aluminum furniture to remove dirt, dust, and any oily residues:

- Mix warm water with a few drops of mild detergent in a bucket.

- Use a soft-bristled brush or sponge to scrub the entire surface.

- Rinse the furniture with clean water to remove any soap residue.

- Allow it to dry completely; this step is crucial for ensuring proper paint adhesion.

3. Lightly Sand the Surface

Sanding creates a slightly roughened surface that allows the primer and paint to adhere better:

- Use fine-grit sandpaper (220-grit) to lightly sand the entire surface of the aluminum.

- Focus on areas with existing scratches or peeling paint.

- After sanding, wipe down the surface with a tack cloth or microfiber cloth to remove any sanding dust.

4. Apply a Suitable Primer

Priming is a vital step in painting aluminum furniture:

- Choose a primer that is specifically designed for metal surfaces and is compatible with aluminum.

- Apply the primer evenly using a brush or spray method.

- Follow the manufacturer’s instructions regarding drying times. A well-primed surface ensures that the paint bonds properly and lasts longer.

5. Paint the Aluminum Furniture

Once the primer is fully dry, you can start painting:

- Select a high-quality acrylic or enamel paint suitable for metal surfaces.

- Apply the paint in thin, even coats, using a brush or spray gun for best results.

- Allow each coat to dry thoroughly before applying the next. Multiple thin coats are preferable to one thick coat, as this reduces the risk of drips and uneven coverage.

- For a uniform finish, consider using a paint sprayer if available.

6. Apply a Protective Topcoat (Optional)

To enhance durability and resistance to weather:

- Once the paint is completely dry, apply a clear protective topcoat.

- This step is particularly recommended for outdoor furniture to protect the finish from UV rays, moisture, and abrasion.

7. Allow the Finished Piece to Cure

Proper curing is essential for achieving a long-lasting finish:

- Follow the paint manufacturer’s recommendations regarding curing times.

- Avoid heavy use or exposure to harsh weather conditions until the paint has fully cured.

Tips for Best Results

- Test in a Small Area: Before painting the entire piece, test your primer and paint on a small, inconspicuous area to ensure compatibility and desired results.

- Work in a Dust-Free Environment: Ensure that the area is free of dust and debris during the painting process to prevent imperfections.

- Monitor Weather Conditions: For outdoor projects, choose a day with mild, dry weather to avoid issues with moisture and temperature fluctuations.

- Maintain Your Painted Furniture: Regular cleaning and occasional touch-ups will keep your painted aluminum furniture looking its best.

ASUZAC ACM: Your Trusted Partner in Aluminum Casting

ASUZAC ACM is a global leader in aluminum casting, known for delivering high-quality cast aluminum parts that set industry benchmarks. With our advanced V-Process technology, we produce aluminum components that are not only strong and durable but also exceptionally smooth and ready for finishing.

Our Advanced V-Process Technology

Our patented V-Process technology revolutionizes the aluminum casting process by using a vacuum-assisted method. This approach offers several key benefits:

- Enhanced Precision: Achieves intricate details and tight tolerances that are critical for high-quality finishes.

- Superior Surface Quality: The V-Process minimizes defects like porosity and shrinkage, resulting in a smooth surface that requires minimal post-processing.

- Improved Strength and Durability: Components cast using the V-Process exhibit a superior strength-to-weight ratio, making them ideal for demanding applications.

- Sustainable Manufacturing: Our process reduces waste and energy consumption, aligning with our commitment to eco-friendly production practices.

Integrated In-House Production

At ASUZAC ACM, we oversee every stage of production—from design and mold fabrication to casting and finishing—ensuring rigorous quality control and the ability to customize products to meet specific client needs. This integrated approach guarantees consistency, reliability, and exceptional quality across all our cast aluminum parts.

Global Expertise with Local Support

With headquarters in Japan and a state-of-the-art manufacturing facility in Vietnam, ASUZAC ACM combines the precision of Japanese craftsmanship with the efficiency of modern production techniques. This dual-location strategy enables us to serve global markets effectively while providing competitive pricing and responsive local support.

Commitment to Sustainability

Sustainability is at the core of our operations. We utilize recyclable materials and energy-efficient production methods, reducing our environmental impact and supporting eco-friendly practices. This commitment to sustainability is a key reason why clients choose ASUZAC ACM for their aluminum casting needs.

Exceptional Customer Service

Our customer-centric approach ensures that we provide personalized support from initial consultation to final delivery. Our experienced team is dedicated to understanding your project requirements and offering tailored solutions that deliver outstanding performance and aesthetic appeal.

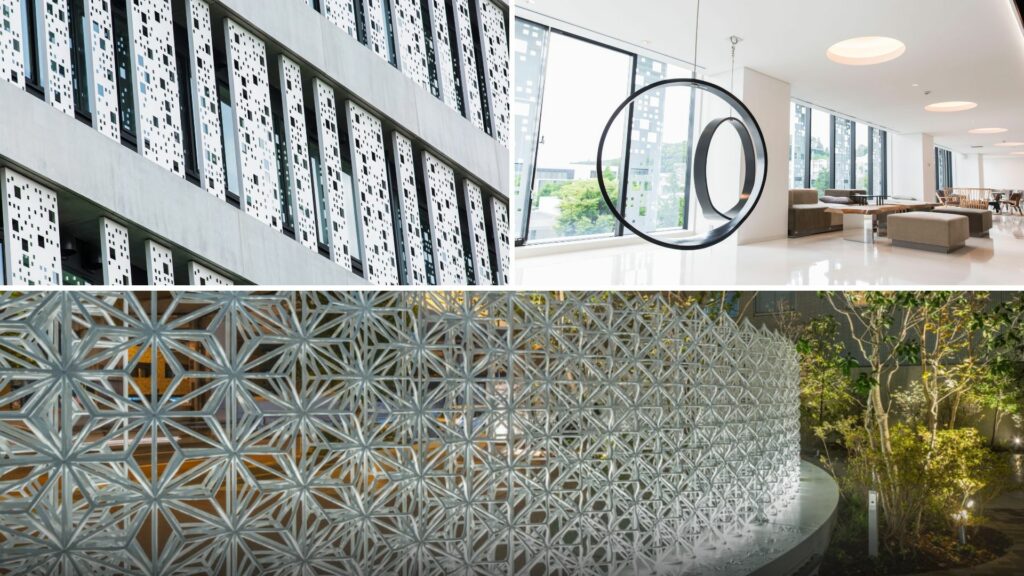

ASUZAC ACM Product Range

Our diverse product range includes high-quality cast aluminum parts designed for various applications:

- Construction: Structural panels, architectural elements, railings, and custom components for modern buildings.

- Furniture: Outdoor and indoor aluminum furniture, including benches, tables, chairs, and decorative accessories.

- Industrial Applications: Precision components for automotive, aerospace, and machinery, engineered for durability and performance.

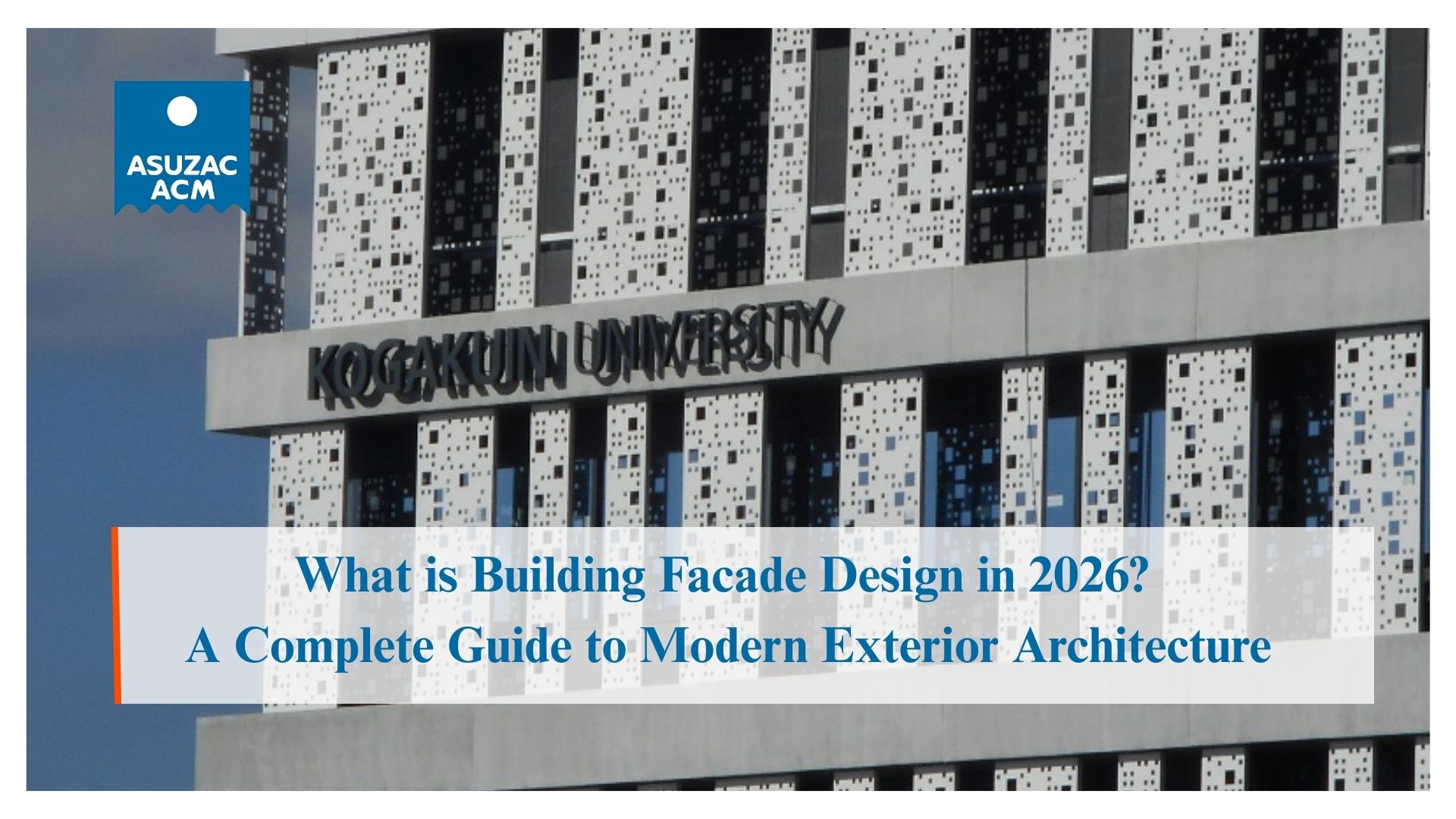

Notable projects showcasing our cast aluminum parts include:

- Showa Women University, Japan: Custom architectural elements that enhance both form and function.

- Ryukoku University Omiya Campus, Japan: Precision components that contribute to a modern, sustainable campus environment.

Frequently Asked Questions (FAQs)

Q: What are the benefits of aluminum casting?

A: Aluminum casting offers benefits such as durability, corrosion resistance, lightweight construction, cost-effectiveness, design flexibility, and sustainability. These attributes make it suitable for various industries, including construction, automotive, aerospace, and furniture.

Q: How do I paint aluminum furniture?

A: To paint aluminum furniture, start by cleaning the surface thoroughly, lightly sanding to create a bonding surface, applying a suitable primer designed for metal, and then painting with high-quality acrylic or enamel paints. A clear protective topcoat can be applied for extra durability.

Q: What makes ASUZAC ACM’s V-Process technology unique?

A: Our V-Process is a vacuum-assisted casting method that minimizes common defects like porosity and shrinkage, resulting in components with exceptional precision, smooth finishes, and enhanced mechanical properties. This innovative process significantly improves the quality and durability of our cast aluminum parts.

Q: What types of products does ASUZAC ACM offer?

A: We offer a wide range of products including structural panels, architectural elements, outdoor furniture (benches, tables, chairs), and industrial components. Our products are used in prestigious projects like Showa Women University and Ryukoku University Omiya Campus in Japan.

Q: How can I contact ASUZAC ACM?

A: You can reach us at:

- Phone: +84 274 376 7136 | +84 093 707 6608

- Email: [email protected]

The process of painting aluminum furniture is an essential part of maintaining its appearance and prolonging its life. With the right preparation, materials, and techniques, you can achieve a flawless finish that enhances both the aesthetic and functional qualities of your aluminum pieces.

Cast aluminum parts offer remarkable strength, durability, and versatility, making them an ideal choice for a wide range of applications. ASUZAC ACM stands at the forefront of the aluminum casting industry, leveraging our innovative V-Process technology to produce high-quality components that excel in performance and aesthetics. Our integrated in-house production, global expertise, and commitment to sustainability ensure that we deliver superior products that meet the highest standards.

Whether you’re looking to repaint your existing aluminum furniture or invest in new, premium cast aluminum components, ASUZAC ACM is your trusted partner for cutting-edge aluminum casting solutions. Our expertise in advanced manufacturing techniques not only guarantees exceptional strength and durability but also makes maintenance—including painting—more efficient and effective.

Contact ASUZAC ACM today to learn more about our products and services, and discover how our innovative solutions can elevate your projects with high-quality, resilient cast aluminum parts.