Part 3: Industrial Applications of V-Process Casting and ASUZAC ACM’s Expertise

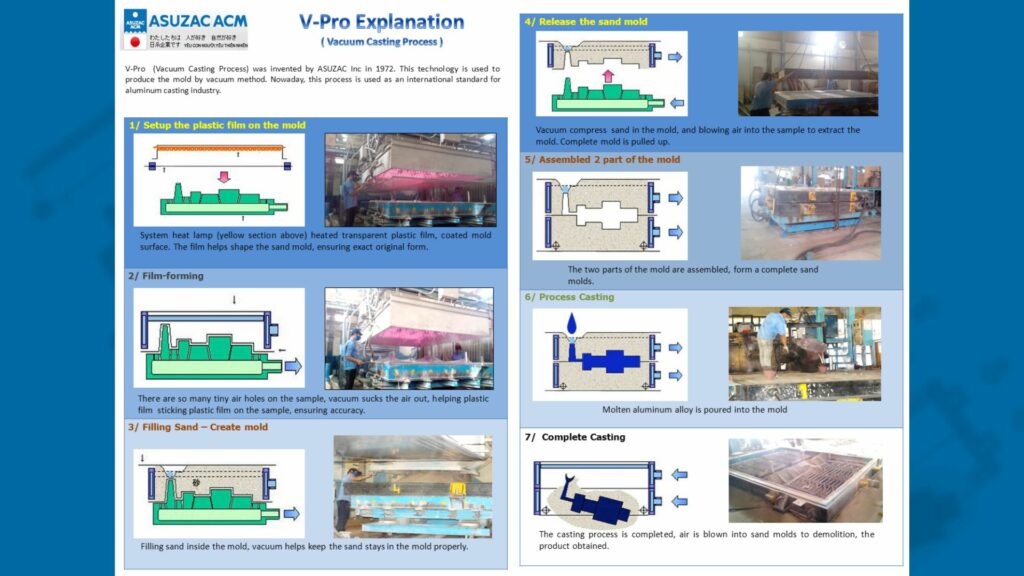

V-process casting is more than a production method—it is a strategic technology for industries requiring precision, durability, and eco-friendly manufacturing. From counterweights to railway parts, V-process has proven its versatility across a wide range of applications.

As a specialist in aluminum casting, ASUZAC ACM combines this technology with expertise to deliver lightweight, high-performance solutions to global clients.

This article explores the industrial applications of V-process casting, why aluminum is an ideal choice, and how ASUZAC ACM sets the benchmark in this field.

Table of Contents

Key Industrial Applications

1. Counterweights

V-process is widely used to produce counterweights for:

- Forklifts.

- Elevators.

- Construction machinery.

With weight ranges from 50 kg to over 5,000 kg, V-process counterweights offer precise dimensions, excellent surface finish, and durability.

2. Wear-Resistant Products

Mining and cement industries require parts that withstand abrasion and impact. V-process enables the production of:

- Liners.

- Crusher parts.

- Impact plates.

The absence of binders reduces defects such as inclusions, extending the service life of these components.

3. Heat-Resistant Components

For industries such as steelmaking and power generation, V-process produces:

- Furnace fittings.

- Exhaust systems.

- Engine parts.

These castings maintain integrity under high temperatures, making them reliable in demanding environments.

4. Railway and Heavy Machinery Parts

V-process is used for large, complex parts such as:

- Swing bolsters and side frames (300–600 kg range).

- Structural parts for locomotives and rolling stock.

Precision molds ensure that these safety-critical components meet international railway standards.

Why Aluminum + V-Process = The Future

While V-process supports multiple metals, aluminum is increasingly preferred due to its:

- Lightweight strength: ideal for automotive and transportation industries.

- Corrosion resistance: extends lifespan in harsh conditions.

- Recyclability: aligns with circular economy goals.

ASUZAC ACM specializes in aluminum alloy castings, providing customers with the advantages of both V-process precision and aluminum’s material performance.

ASUZAC ACM’s Competitive Edge

Engineering Expertise

ASUZAC ACM applies CAE simulation analysis to optimize gating systems, shrinkage allowances, and venting designs. This ensures defect-free castings even in complex geometries.

Customization and Flexibility

From CAD file analysis to pattern development and prototyping, ASUZAC ACM collaborates closely with clients to tailor solutions for specific requirements.

Sustainability Commitment

- Binder-free sand process.

- 100% sand recycling loops.

- Energy-efficient vacuum systems.

This makes ASUZAC ACM a partner of choice for companies pursuing sustainability goals.

Global Standards

Products are manufactured to international quality certifications, serving customers in Asia, Europe, and global markets.

Conclusion

V-process casting has applications across industries where precision, durability, and sustainability are non-negotiable. From counterweights to railway parts, and from wear-resistant to heat-resistant components, V-process delivers proven results.

By specializing in aluminum alloys, ASUZAC ACM takes these benefits further—offering lightweight, durable, and eco-friendly solutions to global industries.

ASUZAC ACM is not only a casting manufacturer but a strategic partner for industries seeking to innovate with reliable and sustainable aluminum castings.