Is Cast Aluminum Strong? Unveiling the Strength and Benefits of Aluminum Casting with ASUZAC ACM

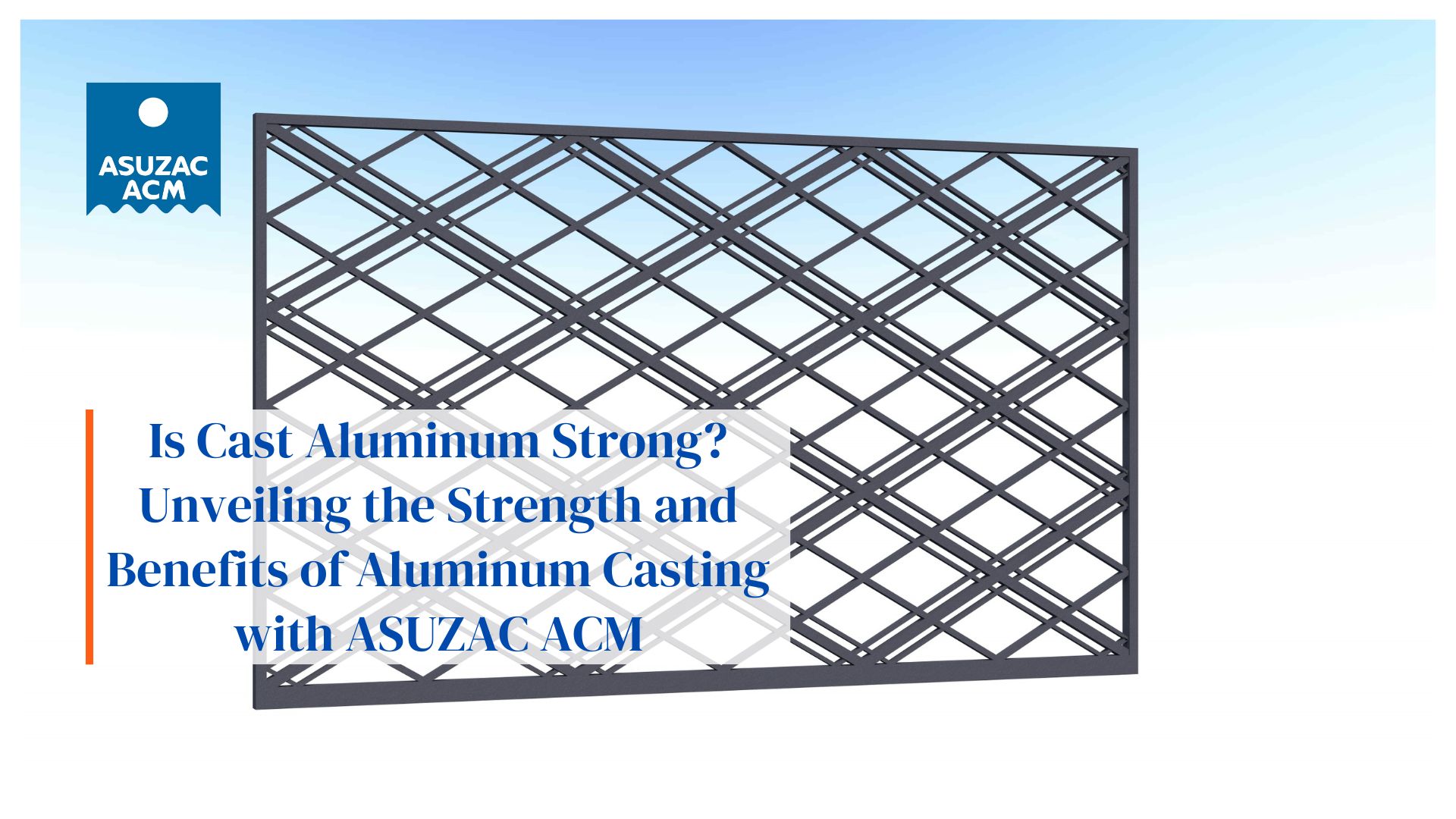

In modern manufacturing, aluminum casting has become a cornerstone process for producing components that combine light weight with exceptional strength and durability. One question that frequently arises is, “Is cast aluminum strong?” The answer lies in understanding the unique properties of aluminum and the advanced techniques used in its casting. Cast aluminum is renowned for its excellent strength-to-weight ratio, making it ideal for a variety of applications—from automotive and aerospace components to high-end furniture and construction elements.

ASUZAC ACM, a leader in aluminum casting and fabrication based in Japan, has perfected the art of aluminum casting through our revolutionary V-Process technology. With state-of-the-art production facilities and a strong commitment to quality and sustainability, we deliver superior cast aluminum components that excel in strength and durability. In this article, we will delve into the properties of cast aluminum, discuss the benefits of aluminum casting, and highlight why ASUZAC ACM stands out as a top manufacturer. We will also

Table of Contents

What is Aluminum Casting?

Aluminum casting is a manufacturing process in which molten aluminum is poured into a mold to create components with precise shapes and intricate details. This process allows for the production of complex designs that would be difficult or impossible to achieve using traditional fabrication methods. Aluminum casting is widely used across industries due to several key advantages:

- Precision: Modern casting techniques allow for tight tolerances and detailed finishes.

- Versatility: Cast aluminum can be molded into a wide range of shapes, from delicate decorative elements to robust structural parts.

- Efficiency: The casting process can produce components quickly and with minimal material waste.

- Eco-Friendliness: Aluminum is fully recyclable, making it a sustainable choice for manufacturers and consumers alike.

Read more about ” What is Aluminum Casting“

Is Cast Aluminum Strong?

The question of strength is vital in determining the suitability of materials for various applications. Cast aluminum is notably strong despite its lightweight nature. Here’s why:

Superior Strength-to-Weight Ratio

One of the standout properties of aluminum is its impressive strength-to-weight ratio. Compared to other metals like steel, aluminum is much lighter while still providing significant structural strength. This means that cast aluminum components can offer robust performance without adding unnecessary weight—a critical factor in industries such as automotive, aerospace, and construction.

Structural Integrity

The casting process allows for the development of components with uniform density and minimal internal defects. Advanced methods like ASUZAC ACM’s patented V-Process technology reduce common casting issues such as porosity and shrinkage. As a result, the final product exhibits enhanced mechanical properties, including improved tensile strength and impact resistance.

Design Optimization

Engineers can design cast aluminum components to maximize strength while minimizing material usage. Through strategic design and the ability to cast complex geometries, parts can be optimized to distribute loads evenly. This design flexibility ensures that cast aluminum components meet rigorous performance standards even under heavy stress.

Applications Requiring Strength

Due to its strength and durability, cast aluminum is used in a multitude of high-stress applications:

- Automotive Components: Engine parts, transmission housings, and structural frames.

- Aerospace: Lightweight yet durable components for aircraft and spacecraft.

- Construction: Structural panels, decorative facades, and support elements.

- Furniture: Outdoor and indoor furniture that requires both elegance and longevity.

Benefits of Aluminum Casting

Beyond its strength, aluminum casting offers a host of additional benefits that make it a preferred manufacturing process:

Durability and Corrosion Resistance

Aluminum naturally forms a protective oxide layer, which significantly enhances its resistance to corrosion. This property ensures that cast aluminum components maintain their integrity and appearance over time, even when exposed to harsh environmental conditions. This is particularly important for outdoor applications and coastal regions.

Lightweight and Cost-Effective

The lightweight nature of aluminum not only contributes to its strength-to-weight advantage but also simplifies handling and transportation. This reduces overall costs in manufacturing, installation, and maintenance. The energy efficiency of the casting process further contributes to cost savings, making aluminum casting an economical choice for large-scale production.

Design Flexibility and Aesthetic Appeal

Aluminum casting supports the creation of complex, aesthetically pleasing designs that are both functional and modern. Whether for intricate architectural elements or streamlined automotive parts, the process allows for high customization. This versatility is particularly valuable in applications where design is as critical as performance.

Sustainability

Aluminum is one of the most sustainable materials available. Its recyclability means that old or unused parts can be reprocessed with minimal energy compared to producing new material. Manufacturers like ASUZAC ACM are committed to sustainable practices, ensuring that our production processes minimize waste and environmental impact.

ASUZAC ACM: Leading the Way in High-Quality Aluminum Casting

ASUZAC ACM is a trailblazer in the aluminum casting industry, known for its innovation, precision, and commitment to quality. With a heritage rooted in Japan and supported by state-of-the-art manufacturing facilities in Vietnam, ASUZAC ACM leverages advanced technologies to produce cast aluminum components that set industry benchmarks.

Our Revolutionary V-Process Technology

At the heart of our manufacturing prowess is the V-Process casting technology—a vacuum-assisted method that revolutionizes aluminum casting. This technology offers several critical advantages:

- Enhanced Precision: The V-Process allows us to achieve extremely tight tolerances and intricate details, ensuring every component meets exact specifications.

- Smooth Surface Finish: By minimizing common casting defects such as porosity and shrinkage, the V-Process produces components with a refined, smooth finish that often requires little to no post-processing.

- Superior Mechanical Properties: The components produced are not only lightweight but also exhibit outstanding strength, making them ideal for high-stress applications.

- Sustainable Production: The process is designed to reduce material waste and energy consumption, aligning with modern eco-friendly manufacturing standards.

Integrated In-House Production

ASUZAC ACM manages every stage of production internally—from design and mold fabrication to casting and final finishing. This integrated approach allows us to maintain strict quality control, ensuring that every product is of the highest standard. It also enables us to offer bespoke solutions tailored to the specific needs of our clients.

Global Expertise with Local Presence

With our headquarters in Japan and a modern manufacturing facility in Vietnam, ASUZAC ACM is uniquely positioned to serve global markets. Our dual-location strategy combines the meticulous craftsmanship of Japanese manufacturing with the efficiency and cost-effectiveness of our Vietnamese operations. This global presence enables us to deliver superior products at competitive prices, backed by responsive local support.

Commitment to Sustainability

Sustainability is at the core of our operations. We employ eco-friendly manufacturing practices that minimize our carbon footprint, reduce waste, and conserve energy. By using 100% recyclable aluminum and implementing efficient production methods, ASUZAC ACM is committed to contributing to a greener, more sustainable future.

Exceptional Customer Service

Our customer-centric approach ensures that we provide tailored support throughout your project, from initial consultation to final delivery. Our dedicated team of experts is always available to help you select the right solutions and ensure that your requirements are met with precision and efficiency.

ASUZAC ACM Product Range

ASUZAC ACM offers a broad range of aluminum cast components designed for diverse applications, including:

Construction

- Structural Panels: High-performance panels that provide both aesthetic appeal and robust support.

- Architectural Elements: Custom-designed decorative features and façade components that enhance modern buildings.

Furniture

- Outdoor Furniture: Durable and stylish benches, tables, and chairs designed for residential and commercial outdoor settings.

- Indoor Components: Sleek aluminum parts used in high-end furniture for a contemporary look and long-lasting performance.

Industrial Applications

- Precision Components: Custom-designed parts for machinery, automotive, and aerospace applications, where reliability and performance are critical.

Our products have been successfully implemented in landmark projects such as:

ASUZAC ACM’s expertise is showcased in several landmark projects that underscore the strength and reliability of our cast aluminum products. These projects serve as a testament to the superior performance of our components in demanding applications:

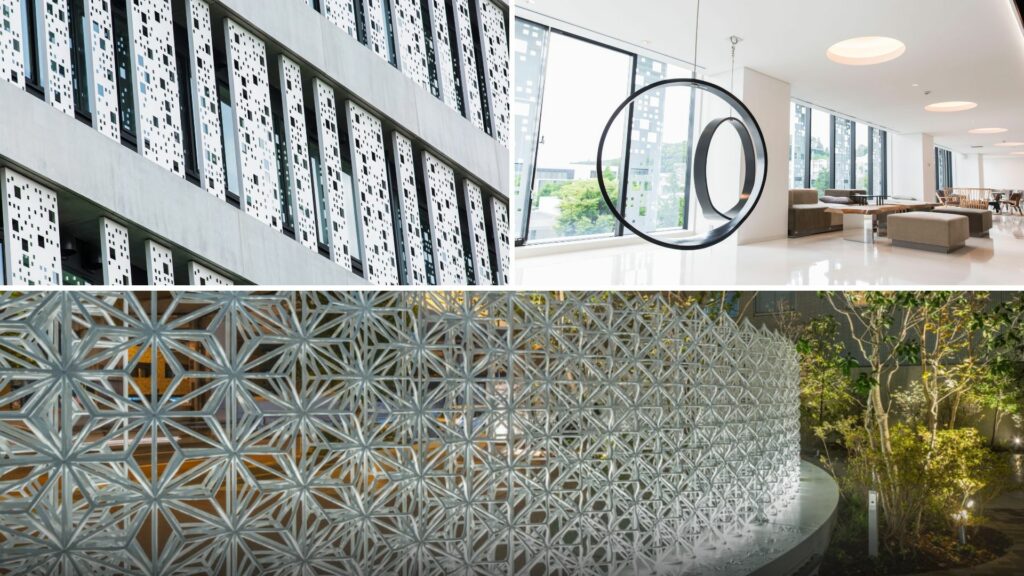

Showa Women University, Japan

At Showa Women University, our precision-cast aluminum components were used to create architectural elements and structural panels that enhance both the functionality and aesthetics of the campus. The durability of our products ensures that these installations continue to perform under heavy usage and varying weather conditions.

Ryukoku University Omiya Campus, Japan

At Ryukoku University Omiya Campus, our cast aluminum components have been integrated into various outdoor and structural applications. The robust design and lightweight nature of our products have contributed to creating a modern, sustainable campus environment that meets both aesthetic and functional requirements.

Takada Train Station, Japan

In the Takada Train Station project, our aluminum castings were employed in the construction of both structural supports and decorative elements. The combination of strength, precision, and a smooth finish made our products an ideal choice for this high-traffic public infrastructure, ensuring safety and durability while enhancing visual appeal.

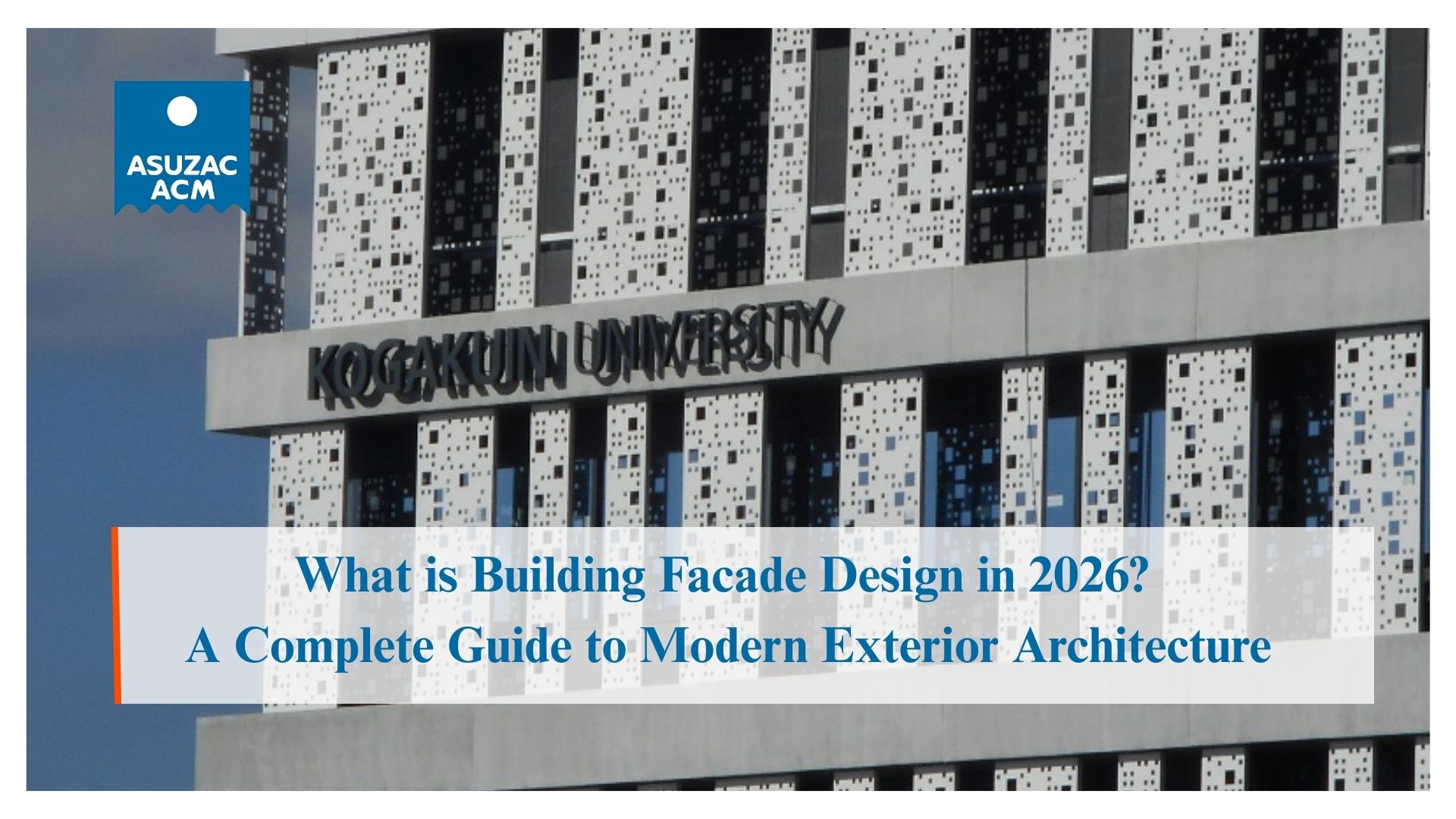

Kogakuin University, Japan

For Kogakuin University, our cast aluminum components were used to create custom-designed elements for both exterior facades and interior features. The ability to produce complex, high-precision parts allowed us to deliver solutions that not only contribute to the structural integrity of the buildings but also elevate the overall design.

These projects are a testament to our ability to deliver components that combine strength, precision, and aesthetic excellence.

Frequently Asked Questions (FAQs)

Q: How does aluminum casting benefit various industries?

A: Aluminum casting provides several benefits, including high precision, design flexibility, durability, lightweight construction, and eco-friendliness. These advantages make it suitable for automotive, aerospace, construction, and furniture applications, among others.

Q: What makes ASUZAC ACM’s V-Process technology unique?

A: Our V-Process is a vacuum-assisted casting method that produces aluminum components with exceptional precision, smooth surface finishes, and enhanced mechanical properties. It minimizes defects like porosity and shrinkage, resulting in superior, high-quality products that require minimal post-processing.

Q: What types of products does ASUZAC ACM offer?

A: We offer a wide range of products including structural panels, architectural elements, outdoor furniture (benches, tables, chairs), indoor furniture components, and custom-designed industrial parts. Our products are used in prestigious projects like Showa Women University and Ryukoku University Omiya Campus in Japan.

Q: How does ASUZAC ACM ensure the quality of its aluminum castings?

A: We manage every step of the production process in-house, ensuring rigorous quality control from design and mold fabrication to final finishing. Our advanced V-Process technology and integrated production methods guarantee consistent excellence and adherence to high industry standards.

Q: How can I contact ASUZAC ACM?

A: You can reach us at:

- Phone: +84 274 376 7136 | +84 093 707 6608

- Email: [email protected]

The question “is cast aluminum strong?” is not only about weight but also about performance. Cast aluminum offers an ideal combination of light weight and robust strength, making it a superior material for a variety of applications. Its durability, corrosion resistance, and design flexibility make it a preferred choice in sectors ranging from construction to high-end furniture manufacturing.

ASUZAC ACM leads the industry in aluminum casting by leveraging our advanced V-Process technology, which ensures that every component we produce is precise, durable, and aesthetically appealing. Our integrated in-house production, global expertise, and commitment to sustainability set us apart from the competition. Whether you’re looking to enhance your construction projects, upgrade your furniture, or develop custom industrial solutions, ASUZAC ACM is your trusted partner for high-quality cast aluminum components.

Contact ASUZAC ACM today to learn more about our innovative aluminum casting solutions and discover how our expertise can help your projects achieve new heights in strength and performance.