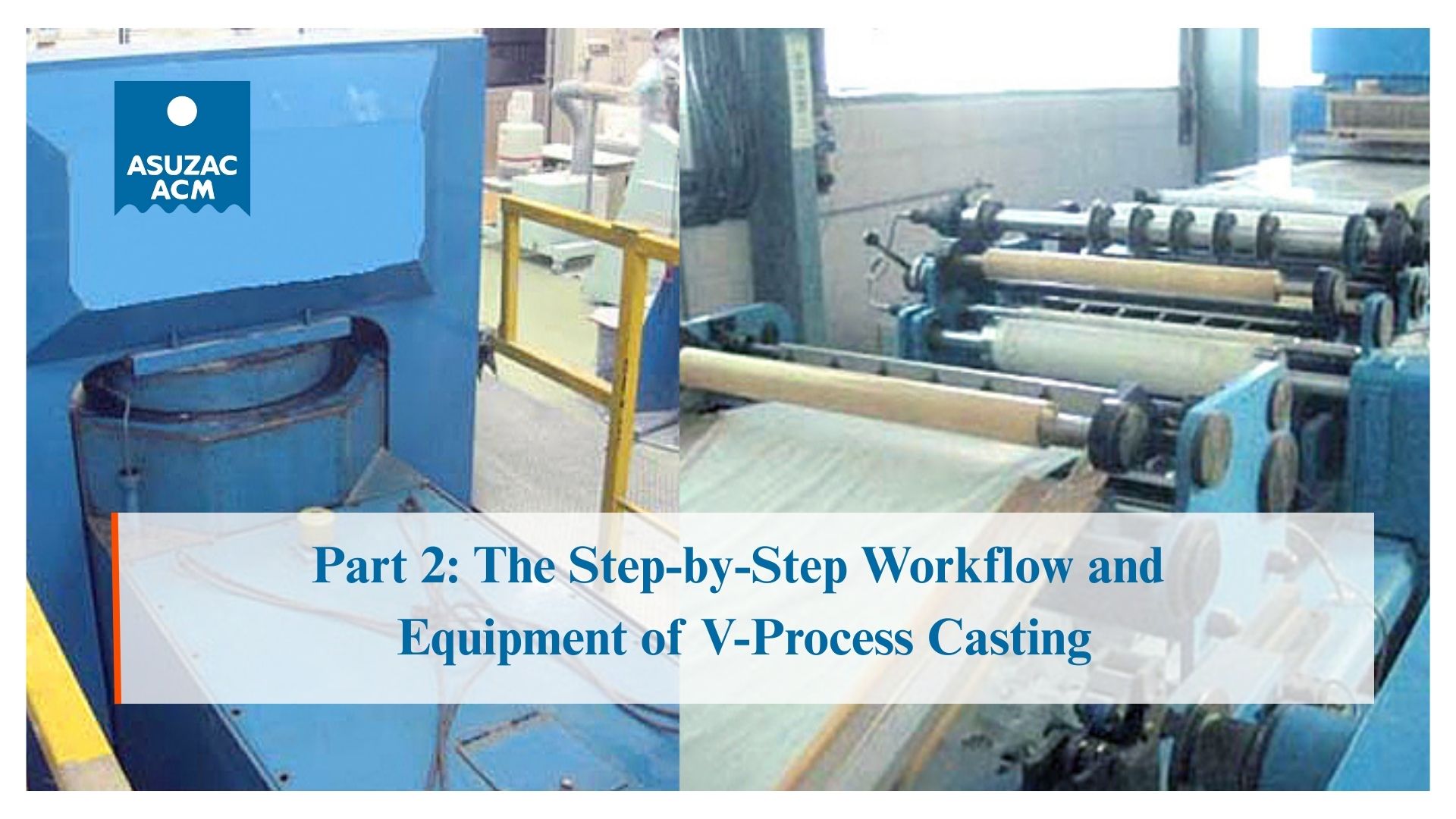

Part 2: The Step-by-Step Workflow and Equipment of V-Process Casting

Behind every successful casting lies a carefully engineered process supported by modern equipment. The V-process (Vacuum Process Casting) is unique not only because it eliminates chemical binders, but also because it requires a highly coordinated system of machinery and controls.

As a leading aluminum casting manufacturer, ASUZAC ACM integrates state-of-the-art V-process lines in its facilities. This allows the company to produce high-precision aluminum castings efficiently, consistently, and sustainably.

In this article, we explore the complete V-process casting workflow step by step, examine the equipment behind each stage, and show how ASUZAC ACM ensures accuracy, efficiency, and quality at every level.

Table of Contents

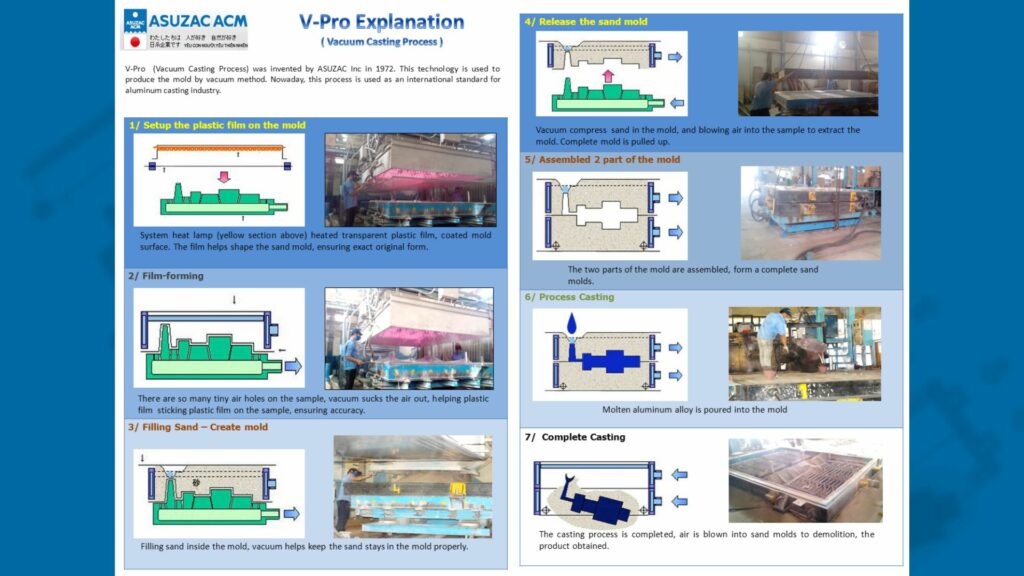

Step 1: Film Heating and Covering

- Equipment: Film heater, vacuum suction table.

The V-process begins with heating a special EVA plastic film until it becomes soft and pliable. The film is then placed over the pattern and vacuum suction pulls it tightly across the surface, capturing every detail of the design.

Why it matters:

- Ensures precise replication of the pattern.

- Provides smooth mold surfaces that translate into superior casting finishes.

Step 2: Coating Application and Drying

- Equipment: Spray booth, drying oven.

A refractory coating is applied over the film to strengthen the mold and protect it from molten aluminum during pouring. After coating, the mold is thoroughly dried to prevent surface defects.

Why it matters:

- Reduces reaction between molten metal and mold surface.

- Improves surface roughness and prevents penetration defects.

Step 3: Flask Setting and Sand Filling

- Equipment: Vibrating table, sand filling system.

An empty flask is positioned over the pattern, and dry, unbonded sand is poured in. The vibrating table compacts the sand to achieve high density and stability.

Why it matters:

- Produces rigid, uniform molds.

- Eliminates weak zones that could cause casting defects.

Step 4: Film Sealing and Vacuum Hardening

- Equipment: Vacuum pump, film applicator.

A second film is placed on the back surface of the mold, and vacuum suction is applied. The negative pressure binds the sand grains together, turning the loose sand into a rigid, stable mold.

Why it matters:

- Creates molds strong enough to withstand pouring without chemicals.

- Ensures dimensional stability throughout the casting cycle.

Step 5: Mold Stripping and Assembly

- Equipment: Manipulators, lifting systems.

The hardened mold is stripped from the pattern using mechanical arms or lifting machines. It is then assembled with its counterpart to form the complete mold cavity.

Why it matters:

- Prevents damage during handling.

- Reduces setup time in large-scale production.

Step 6: Pouring Under Vacuum

- Equipment: Pouring furnace, vacuum system.

Molten aluminum is poured into the mold while the vacuum is maintained. The negative pressure ensures smooth metal flow, filling even thin and complex sections.

Why it matters:

- Reduces porosity and shrinkage defects.

- Improves dimensional accuracy of final castings.

Step 7: Cooling, Shakeout, and Sand Recovery

- Equipment: Shakeout station, sand reclamation system.

Once solidification is complete, the vacuum is released. The mold collapses, and sand flows freely back to the hopper for reuse. This process is nearly 100% recyclable.

Why it matters:

- Reduces material costs.

- Achieves eco-friendly, sustainable production.

ASUZAC ACM’s Equipment Advantage

Unlike smaller foundries, ASUZAC ACM operates fully integrated V-process lines that include:

- Automated sand filling and recycling systems.

- Multi-stage vacuum systems for precise mold control.

- Advanced manipulators for safe and efficient mold handling.

- CAE simulation tools to optimize gating systems and casting design.

This integration allows ASUZAC ACM to produce complex aluminum castings at scale, while maintaining high accuracy and consistency.

Conclusion

The V-process workflow is a balance of precision engineering and advanced equipment. Every stage, from film heating to sand reclamation, contributes to the quality of the final product.

At ASUZAC ACM, these principles are elevated with state-of-the-art equipment and decades of expertise. The result: aluminum castings that