PPG Liquid Coatings for Architectural Aluminum: Why ASUZAC ACM Chooses DURANAR®, DURANAR SUNSTORM®, and DURANAR XL® Systems

When it comes to protecting high-value architectural cast aluminum products that are exposed to the harshest tropical sun, acid rain, salt spray, and urban pollution for decades, only the most advanced coating technology will do.

That is why ASUZAC ACM – Japan’s leading precision aluminum casting manufacturer – partners with PPG Industries, the inventor of 70% PVDF (polyvinylidene fluoride) liquid coatings, and applies the legendary DURANAR® family of liquid extrusion coatings on every exterior architectural product: facades, gates, balconies,….

Using our proprietary V-Process casting technology combined with PPG’s 70% Kynar 500®/Hylar 5000® resin-based liquid coatings, ASUZAC ACM delivers architectural aluminum that remains color-true and gloss-retentive for over 40 years – as proven on iconic projects across Japan and Southeast Asia.

This comprehensive guide dives deep into the three premium liquid coating systems ASUZAC ACM specifies:

- DURANAR® Coatings – The original two-coat benchmark

- DURANAR SUNSTORM® Coatings – Two-coat pearlescent/metalescent brilliance

- DURANAR XL® Coatings – Three- and four-coat ultimate protection for aggressive environments

All three systems meet or exceed AAMA 2605 – the most stringent voluntary specification for architectural coatings in the world.

Table of Contents

Why ASUZAC ACM Trusts Only PPG 70% PVDF Liquid Coatings

- Over 50 years of real-world performance – First commercialized in 1965, DURANAR is the longest-standing, most field-proven architectural coating system globally.

- 70% PVDF resin content – The highest fluoropolymer loading in the industry, delivering unmatched resistance to UV degradation, chalking, and fade.

- Wet-on-wet application – Coater-friendly process allows perfect inter-coat adhesion and uniform film build.

- Field repairable – Unlike anodizing or powder, damaged areas can be touched up on-site without visible difference.

- AAMA 2605 compliance – 10-year Florida exposure: ≤5 ΔE color change, ≤8 chalk rating, ≤10% film loss.

- Full PPG warranty backing – Up to 20–30 years depending on system and geographic zone.

1. DURANAR® Two-Coat Liquid Coatings – The Gold Standard for 40+ Years

System Composition

- Patented inhibitive primer: 0.25 ± 0.05 mil

- 70% PVDF color coat containing ceramic & select organic pigments: ≥1.0 mil dry film

- Total nominal DFT: ≥1.25 mil

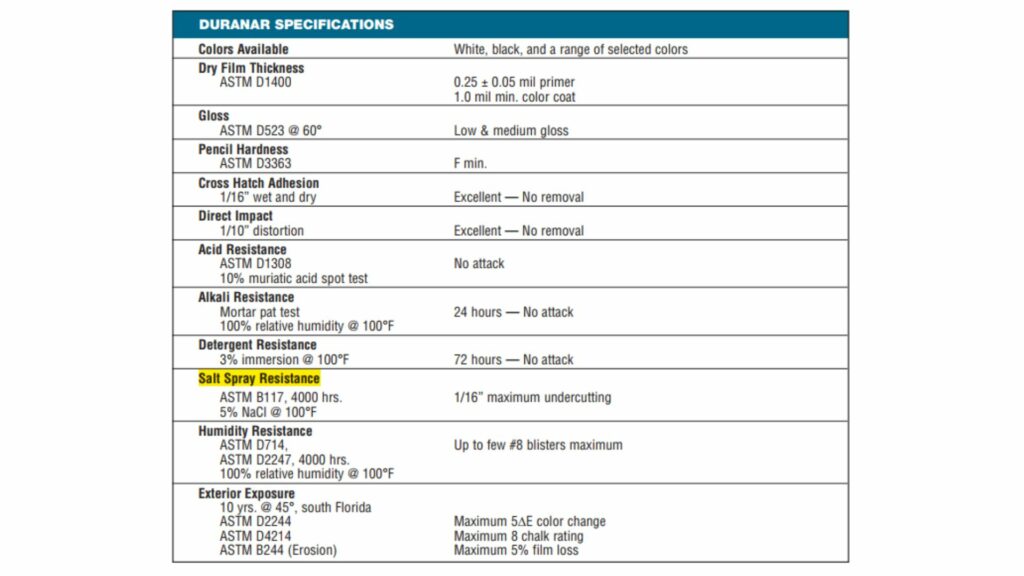

Performance Highlights (AAMA 2605 Tested)

Test | Method | Result |

Salt Spray Resistance | ASTM B117, 4,000 hrs | Max 1/16″ creep from scribe |

Humidity Resistance | ASTM D2247, 4,000 hrs | Few #8 blisters maximum |

Acid Resistance | 10% HCl spot, 24 hrs | No attack |

Alkali Resistance | Mortar pat, 24 hrs | No attack |

Detergent Resistance | 3% @ 100°F, 72 hrs | No attack |

South Florida Exposure 10 yrs | 45° facing south | ≤5 ΔE Hunter units, ≤8 chalk, ≤5% film loss |

Pencil Hardness | ASTM D3363 | Minimum F |

Cross-Hatch Adhesion (wet/dry) | ASTM D3359 | 5B – no removal |

Ideal Applications at ASUZAC ACM

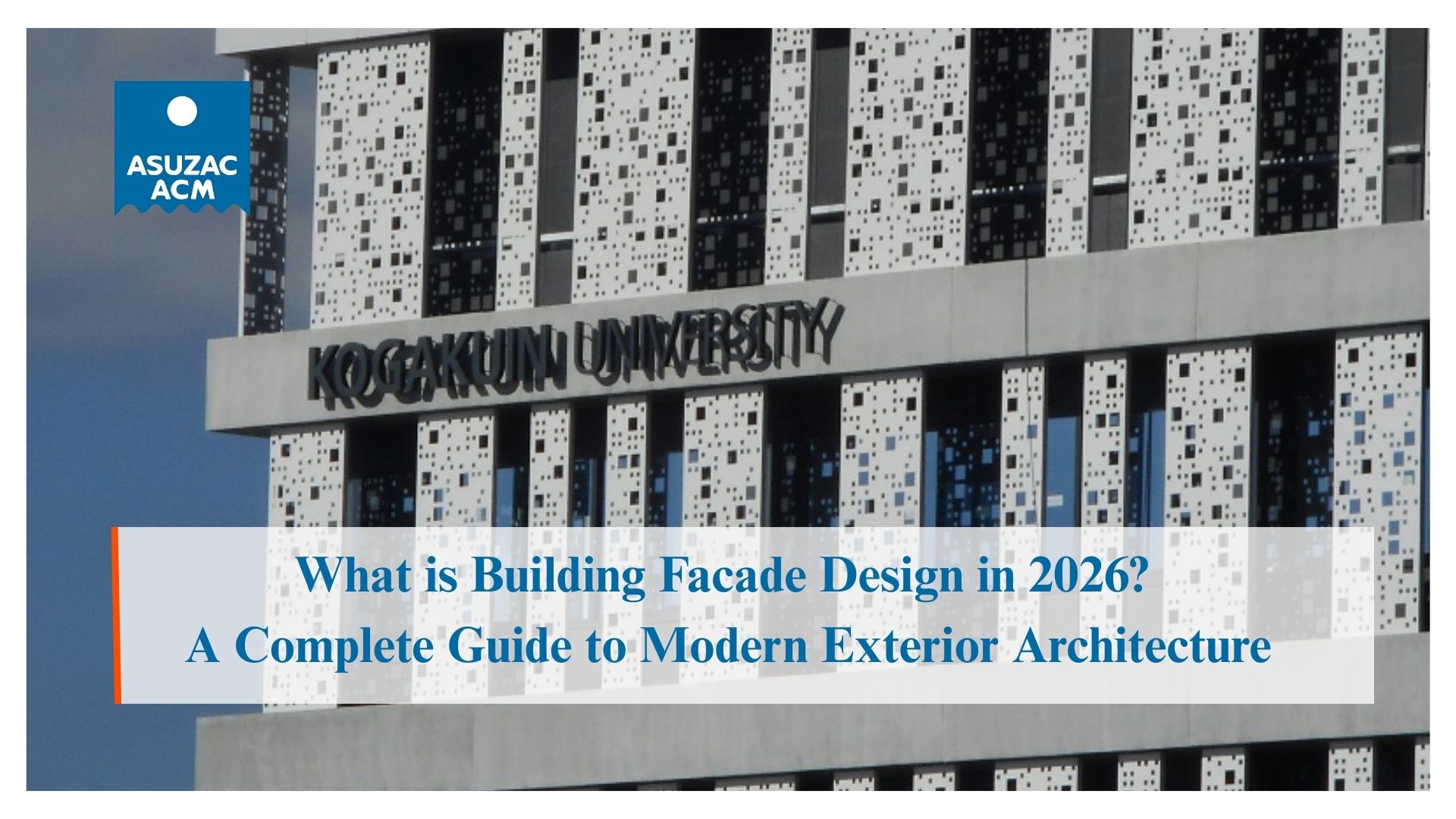

- University & commercial building facades (e.g., Kogakuin University Hachioji Campus)

- Large-scale curtain wall panels

- Storefronts, windows, louvers

- Any project requiring outstanding color consistency and long-term dirt resistance

DURANAR® is the default specification when exceptional aesthetics and proven longevity are required without the need for pearlescent effects or extreme coastal/industrial exposure.

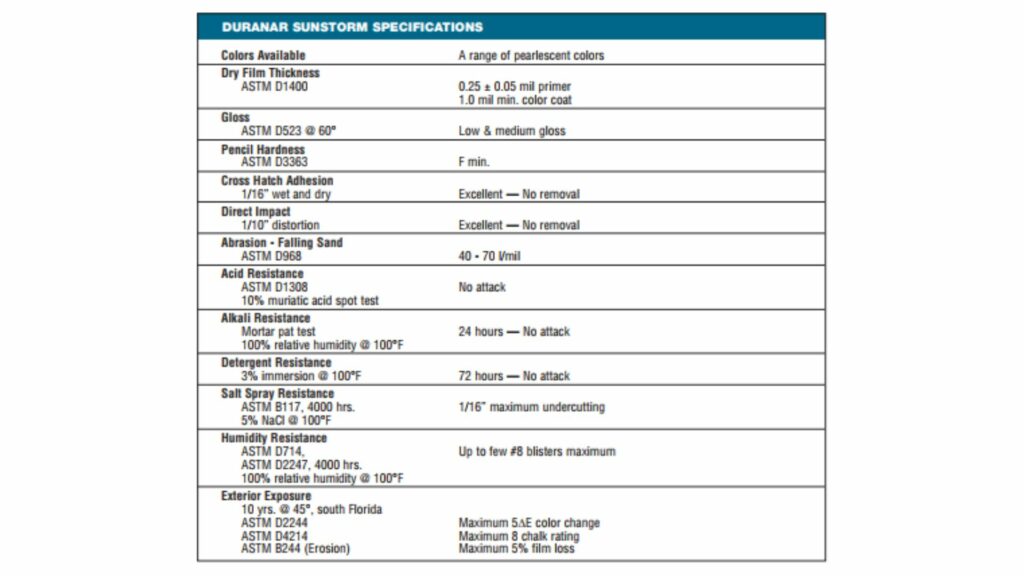

2. DURANAR SUNSTORM® – Two-Coat Pearlescent & Metalescent Brilliance

For architects seeking a shimmering, metallic-like appearance without a clear topcoat (which can sometimes dull mica flakes), ASUZAC ACM specifies DURANAR SUNSTORM®.

Key Features

- Same 70% PVDF resin backbone as standard DURANAR

- Incorporates high-loading mica pearlescent and metallic flakes directly in the color coat

- No clear coat required → brighter, more vivid sparkle

- Available in silvers, champagnes, coppers, golds, and custom pearlescent whites

Performance

Identical AAMA 2605 passing results as standard DURANAR, with the added visual drama of pearlescent flip-flop effects that change appearance with viewing angle and light.

Popular ASUZAC ACM Applications

- Luxury hotel and resort decorative gates and railings

- High-end retail facades

- Signature architectural accents where designers want “liquid metal” look with 30+ year durability

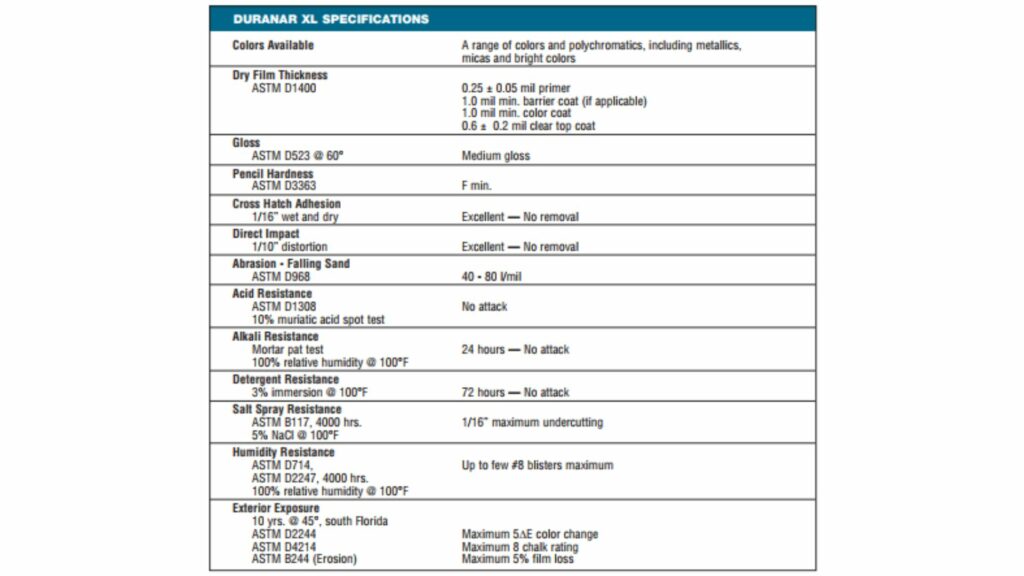

3. DURANAR XL® – Three- & Four-Coat Systems for the Most Aggressive Environments

When projects are located within 1–3 km of the sea or in heavy industrial zones (SO₂, NOx, chemical plants), ASUZAC ACM upgrades to DURANAR XL® – the ultimate protection system.

System Options

Three-coat XL

Primer (0.25 mil) → Color coat (1.0 mil) → Clear 70% PVDF topcoat (0.6–0.8 mil)

Four-coat XL (for metallic, mica, or deep-tone colors)

Primer → Barrier coat → Color/metallic coat → Clear XL topcoat

Why the Clear Topcoat Makes the Difference

- Adds 40–100% more abrasion resistance

- Dramatically improves resistance to acid rain, bird droppings, and industrial fallout

- Extends gloss retention in coastal areas by 50%+ versus two-coat systems

- Required over all metallic and mica flake colors to prevent flake oxidation

Real-World Evidence

PPG maintains exposure sites in Singapore, Dubai, Miami, and industrial Pittsburgh. DURANAR XL panels exposed since 1988 still show:

- <3 ΔE color change after 30+ years

- Gloss retention >70%

- Zero chalking or film erosion

Comparison Table: DURANAR® Family Liquid Coating Systems

Feature | DURANAR® (2-coat) | DURANAR SUNSTORM® (2-coat) | DURANAR XL® (3-/4-coat) |

PVDF Resin Content | 70% | 70% | 70% |

Appearance | Solid & metallic | Pearlescent/metalescent | Solid, metallic, pearlescent |

Clear Topcoat | No | No | Yes (mandatory for metallics) |

Salt Spray (4,000 hrs) | Pass | Pass | Superior performance |

Recommended Environment | General exterior | General exterior | Coastal / Industrial / Aggressive |

Abrasion Resistance | Excellent | Excellent | Outstanding |

Typical Warranty (vertical) | 20–25 years | 20–25 years | 25–30 years |

AAMA Specification | 2605 | 2605 | 2605 |

The ASUZAC ACM + PPG Partnership Advantage

- V-Process Casting + PPG Liquid Coating = Perfection

Our vacuum-sealed V-Process produces zero-porosity, mirror-smooth castings – the ideal substrate for liquid spray coatings that demand perfect surface preparation. - In-House PPG Certified Applicator

ASUZAC ACM operates a state-of-the-art liquid coating line meeting PPG’s strict Certified Applicator Program standards – ensuring every micron of film build and cure is exactly to specification. - Full Traceability & Warranty

Every coated component receives a unique batch number, allowing full traceability to the exact PPG resin lot and cure schedule.

Notable ASUZAC ACM Projects Protected by PPG DURANAR Liquid Coatings

- Kogakuin University Hachioji Campus, Tokyo – Large-format cast aluminum facade panels in DURANAR earth tones

- Showa Women’s University 100th Anniversary Gate – Intricate cast gate in DURANAR XL metallic bronze

- Tam Chuc Pagoda, Vietnam – Lotus-motif cast aluminum balconies in custom DURANAR gold

- Multiple 5-star coastal resorts – Gates, railings, and furniture in DURANAR XL for maximum salt-spray resistance

Ready to Specify the World’s Best Architectural Coating?

Contact ASUZAC ACM today to discuss which DURANAR liquid coating system is perfect for your next project:

- Phone: +84-937-076-608

- Email: [email protected]

- Get a Quote: Contact Us

- Learn about our casting process: V-Process Technology

When you demand architectural aluminum that looks freshly installed after 30–40 years in the harshest climates on earth – there is only one combination trusted by Japan’s most demanding architects:

ASUZAC ACM precision cast aluminum + PPG DURANAR 70% PVDF liquid coatings.