Supply Aluminum Facade Panels in Vietnam: High-Quality Solutions from Japan’s Leading Manufacturer ASUZAC ACM

In the rapidly evolving construction industry, the demand to supply aluminum facade panels in Vietnam has surged, driven by the country’s booming urban development and architectural innovation. As a key component in modern building design, aluminum facades offer a blend of aesthetics, durability, and functionality that appeals to architects, builders, and developers worldwide. For customers seeking high-quality suppliers, Vietnam emerges as a strategic hub due to its cost-effective manufacturing, skilled workforce, and proximity to major Asian markets. This article delves into the essentials of aluminum facade panels, their benefits, and why partnering with a reputable manufacturer like ASUZAC ACM can elevate your projects to new heights.

Table of Contents

What Are Aluminum Facade Panels?

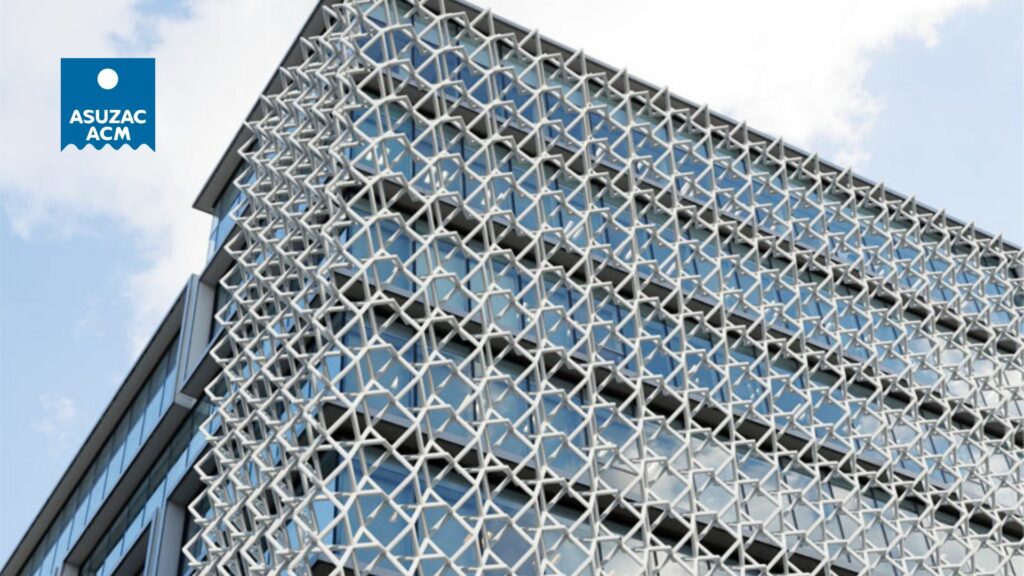

Aluminum facade panels are lightweight, versatile cladding materials used to cover the exterior of buildings, providing both protective and decorative functions. These panels are typically made from aluminum alloys or composite materials, engineered to withstand environmental challenges while enhancing the visual appeal of structures. In the context of supplying aluminum facade panels in Vietnam, these products often incorporate advanced casting techniques to achieve precise shapes, textures, and finishes.

The parent term “aluminum facade” encompasses a broader range of systems, including curtain walls, ventilated facades, and rainscreen cladding. Aluminum facade panels fit into this category as modular elements that can be customized for various applications, from high-rise skyscrapers to commercial complexes. They are prized for their ability to integrate seamlessly with other building materials, offering options like perforated designs for ventilation or solid sheets for insulation. When sourcing aluminum facade panels in Vietnam, it’s crucial to consider factors such as material thickness, coating types (e.g., powder-coated or anodized), and compliance with international standards like ASTM or EN norms.

Benefits of Using Aluminum Facade Panels in Construction

The popularity of aluminum facades stems from their numerous advantages, making them an ideal choice for projects requiring longevity and style. First and foremost, aluminum is exceptionally durable, resistant to corrosion, UV radiation, and extreme weather conditions—perfect for tropical climate with its heavy rains and high humidity. This resilience translates to lower maintenance costs over time, as panels retain their appearance without frequent repainting or repairs.

Energy efficiency is another key benefit. Aluminum facade panels can be designed with thermal breaks or insulating cores, contributing to better building insulation and reduced energy consumption for heating or cooling. In sustainable architecture, these panels support green building certifications like LEED by incorporating recyclable materials and promoting natural ventilation through ventilated facade systems.

Aesthetically, aluminum facades allow for endless creativity. Panels can be shaped, colored, and textured to mimic natural materials like wood or stone, or to create bold, modern looks with metallic finishes. For customers (architectures, engineers,…) looking for supplier of aluminum facade panels in Vietnam, this flexibility means tailored solutions that align with global design trends while adhering to local building codes.

Moreover, aluminum’s lightweight nature simplifies installation, reducing labor costs and project timelines. Compared to heavier materials like steel or concrete, aluminum panels are easier to transport and mount, which is particularly advantageous in Vietnam’s fast-paced construction sector. Safety features, such as fire-resistant coatings, further enhance their appeal for high-traffic buildings like airports, hospitals, and educational institutions.

Introducing ASUZAC ACM: Japan’s Leading Aluminum Casting Manufacturer in Vietnam

For those seeking supplier of aluminum facade panels in Vietnam, ASUZAC ACM, the leading aluminum casting manufacturer from Japan in Vietnam, represents the pinnacle of expertise and reliability. With roots tracing back to 1972, ASUZAC ACM has pioneered aluminum casting technologies, starting with the development of the V-Process in collaboration with the Industrial Research Institute of Nagano Prefecture. Over five decades, the company has built a legacy of innovation, producing high-quality aluminum components for construction, infrastructure, and architectural applications.

Operating from its state-of-the-art facility in Ho Chi Minh City, Vietnam, ASUZAC ACM combines Japanese engineering standards with local manufacturing prowess. This strategic location in the Vietnam-Singapore Industrial Park allows for efficient production and distribution, catering to foreign customers who value precision and sustainability. The company’s integrated in-house processes—from design to final manufacturing—ensure consistent quality, reduced lead times, and customized solutions. ASUZAC ACM’s commitment to excellence is evident in its adoption by over 150 enterprises worldwide, making it a trusted partner for global projects requiring durable aluminum facades.

What sets ASUZAC ACM apart is its focus on environmentally conscious practices. By minimizing waste and energy use, the company aligns with international demands for sustainable building materials. Foreign clients benefit from ASUZAC’s global footprint, including partnerships that emphasize innovation and problem-solving in real-world scenarios. Whether you’re an architect in Europe or a developer in the US, ASUZAC ACM provides the assurance of top-tier products that meet or exceed international standards.

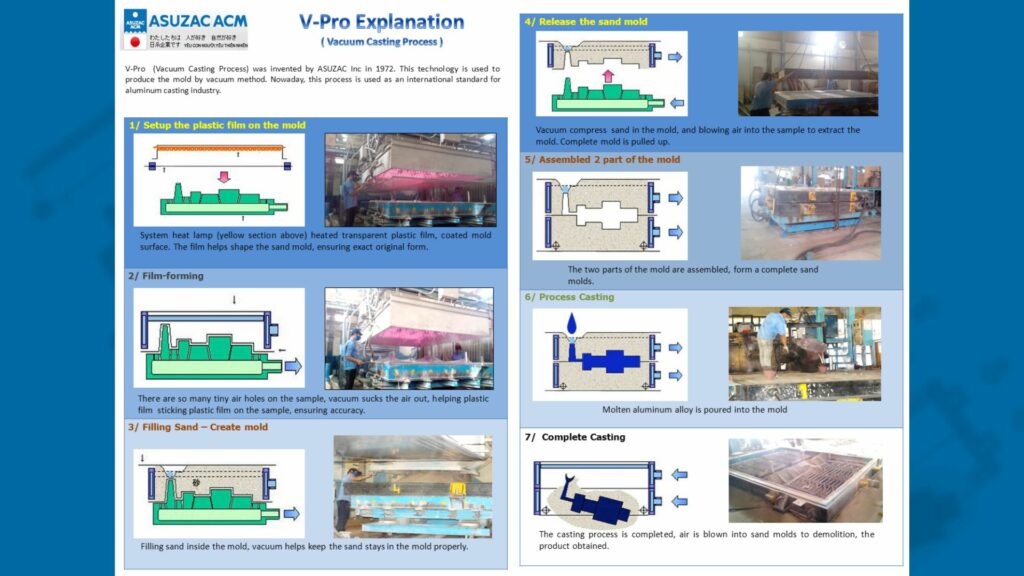

Advanced Technology: The V-Process Advantage

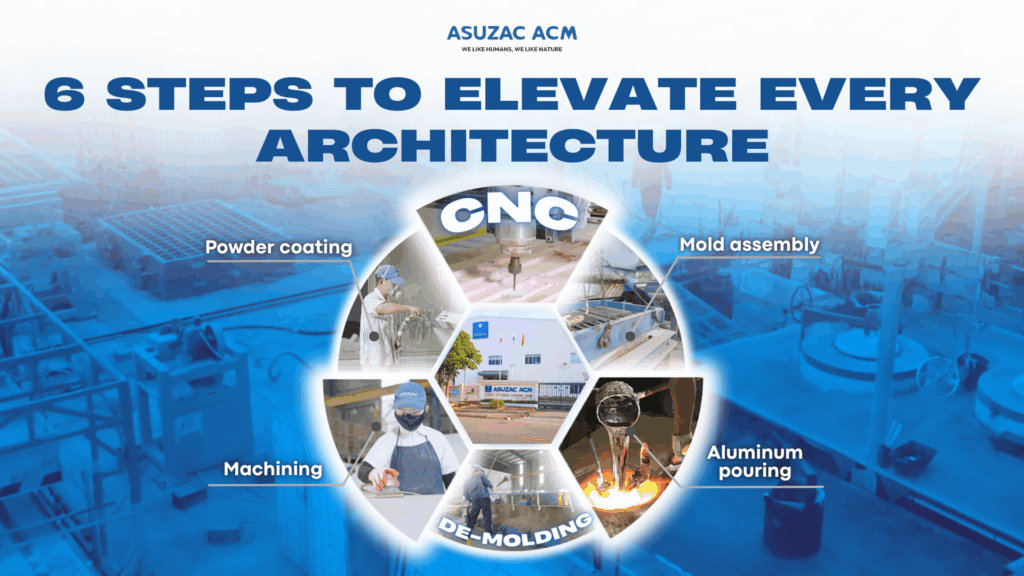

At the heart of ASUZAC ACM‘s success is its patented V-Process casting technology, a vacuum-based method that revolutionizes aluminum production. Unlike traditional sand casting, which relies on binders that generate waste, the V-Process uses a thin plastic film heated and vacuum-sealed over a wooden mold. Fine sand is then added and evacuated to form a precise mold without solidifying agents. Molten aluminum is poured in, and once cooled, the sand naturally collapses, allowing easy removal and reuse.

This technology offers significant advantages for producing aluminum facade panels. It ensures smooth surfaces, precise dimensions, and minimal defects like air pockets, resulting in panels with superior texture and durability. The reusability of sand reduces industrial waste, promoting low pollution, resource conservation, and energy efficiency—key for eco-friendly projects. In applications like facade cladding, the V-Process enables complex designs with high repeatability, ideal for large-scale supplies where consistency is paramount.

By leveraging this innovative approach, ASUZAC ACM delivers aluminum facade panels that are not only high-performing but also cost-effective over their lifecycle. This makes it an excellent choice for foreign customers aiming to supply aluminum facade panels in Vietnam while prioritizing sustainability and quality.

Notable Projects Featuring ASUZAC ACM Facades

ASUZAC ACM’s expertise is best illustrated through its successful projects, showcasing the real-world application of their aluminum facade solutions.

One standout example is the Ho Chi Minh Metro Line 1, a major infrastructure initiative in Vietnam. ASUZAC ACM supplied high-precision cast aluminum panels for the Ben Thanh Market Station, contributing to the station’s modern aesthetic and functional design. These panels provided durable cladding that withstands urban environmental stresses, enhancing the metro’s overall appeal and longevity. This project demonstrates ASUZAC’s capability to handle large-scale, public infrastructure demands, making them a go-to supplier for similar ventures in Vietnam.

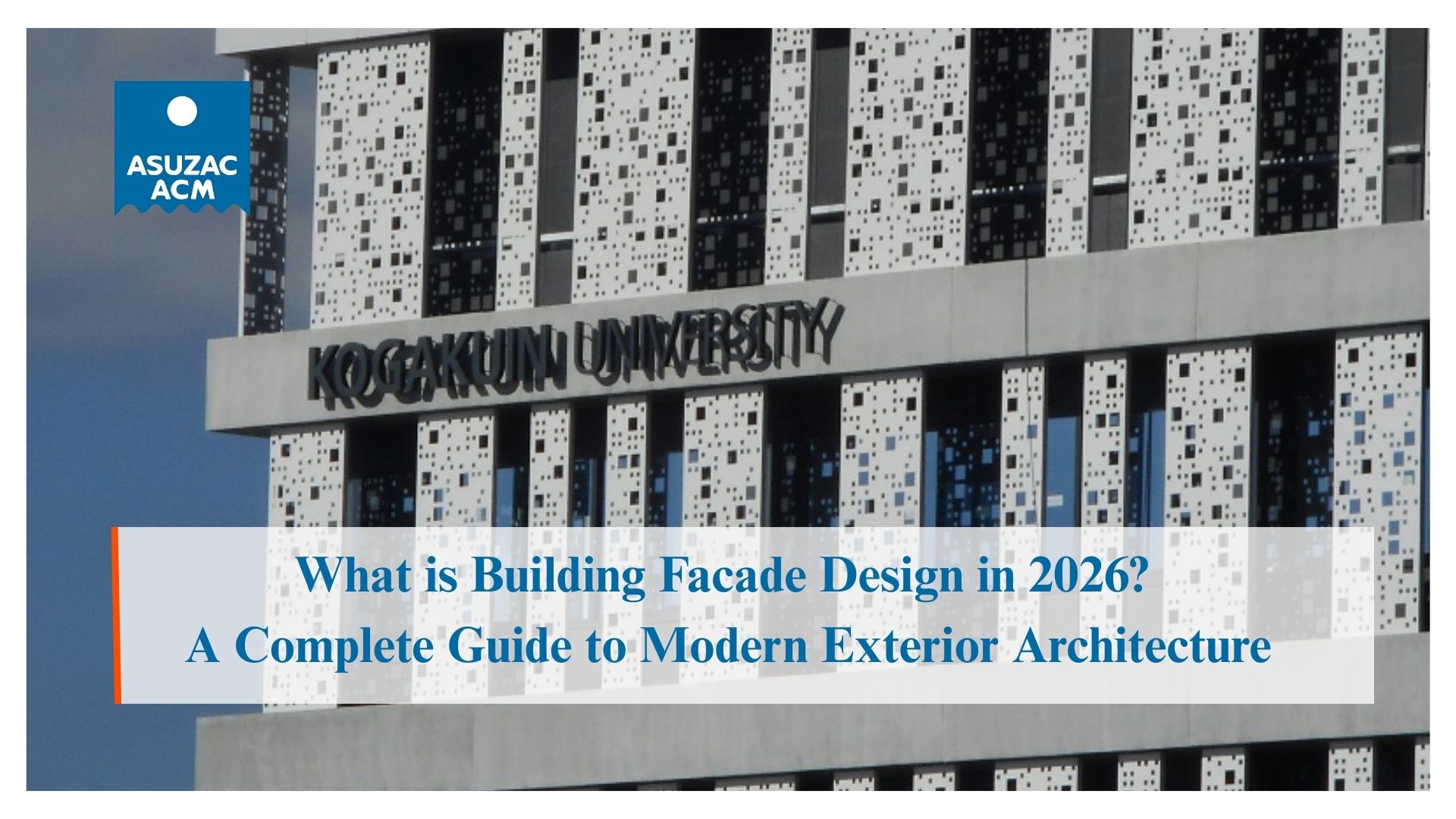

Internationally, ASUZAC ACM contributed to the Kogakuin University of Technology & Engineering (Hachioji Campus), where painted aluminum panels were used for the exterior walls across the entire campus. Incorporating innovative student-inspired designs, these panels created an inspiring environment for learning and interaction. The project’s focus on aesthetics and durability highlights how ASUZAC’s aluminum facades can transform educational spaces, offering ventilated and weather-resistant solutions that promote comfort and creativity.

These projects underscore ASUZAC ACM’s versatility, from urban transport in Vietnam to academic facilities in Japan, proving their aluminum facade panels’ reliability for diverse global applications.

Choosing the Right Supplier for Aluminum Facade Panels in Vietnam

Selecting a supplier involves evaluating factors like production capacity, quality control, and after-sales support. In Vietnam, where the market is competitive, opt for manufacturers with proven technologies and international experience. ASUZAC ACM excels here, offering end-to-end services from consultation to delivery. Their focus on customization ensures panels match your project’s specifications, whether for residential towers or commercial hubs.

Additionally, consider logistics: Vietnam’s ports and airports facilitate efficient shipping, but a reliable supplier like ASUZAC minimizes delays through streamlined processes. Pricing is competitive, but prioritize value—high-quality panels reduce long-term costs through durability and low maintenance.

Conclusion: Partner with ASUZAC ACM for Your Aluminum Facade Needs

In summary, the opportunity to supply aluminum facade panels in Vietnam is ripe for foreign customers seeking quality, innovation, and affordability. ASUZAC ACM stands as a premier choice, blending Japanese heritage with Vietnamese manufacturing to deliver exceptional aluminum facade solutions. From their groundbreaking V-Process technology to landmark projects like Ho Chi Minh Metro Line 1 and Kogakuin University, ASUZAC ACM proves its commitment to excellence.

If you’re ready to elevate your construction projects with top-tier aluminum facades, contact us today to discuss your requirements. Let’s build the future together.