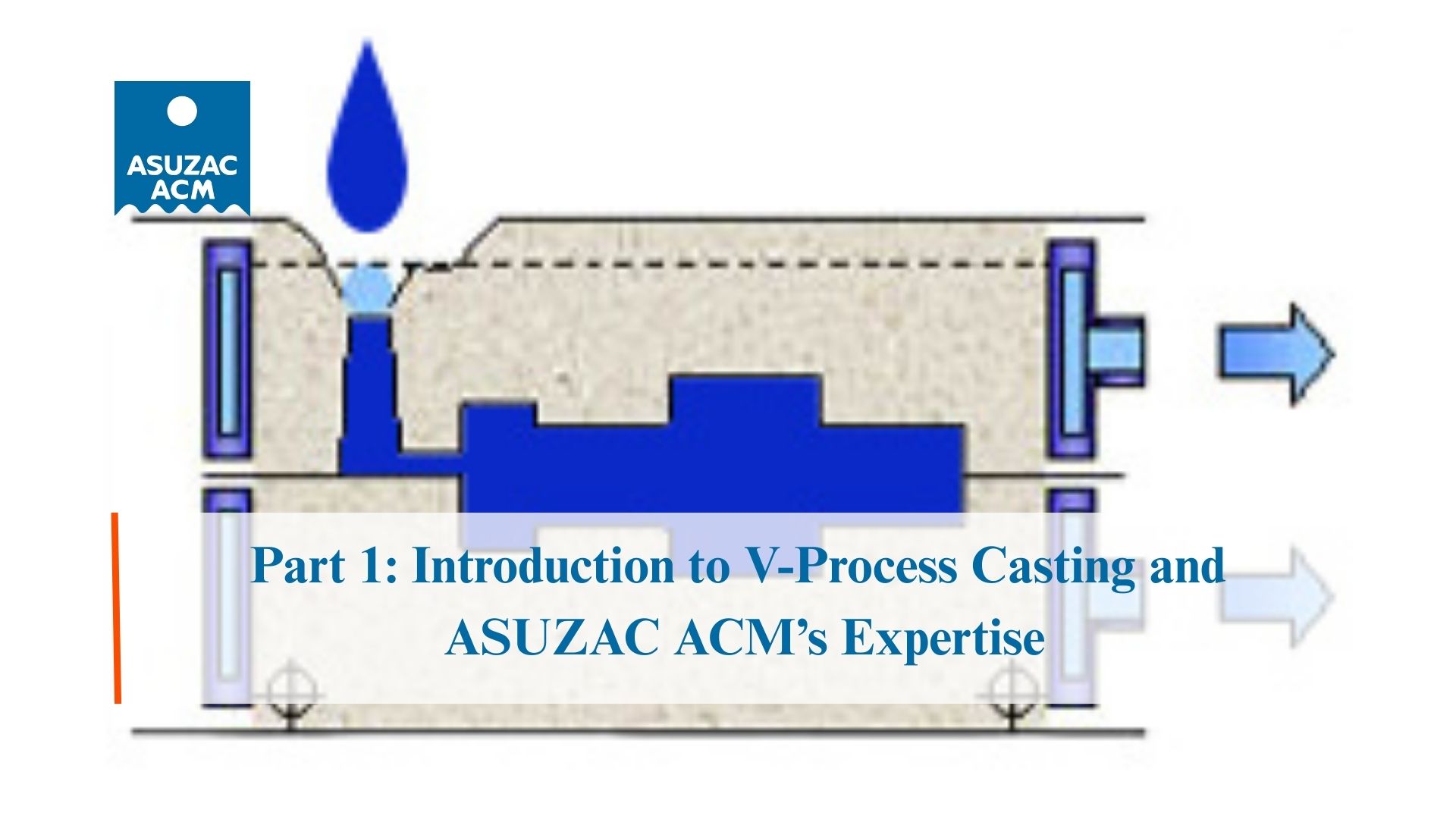

Part 1: Introduction to V-Process Casting and ASUZAC ACM’s Expertise

In modern foundry technology, achieving precision, surface quality, and environmental responsibility has become a global challenge. Traditional casting methods—such as green sand or chemically bonded sand—have limitations when it comes to dimensional accuracy, surface finish, and environmental impact. To overcome these constraints, the V-process (Vacuum Process Casting) was developed.

Today, the V-process is recognized worldwide as a reliable and sustainable solution. At the forefront of this innovation is ASUZAC ACM, a global leader in aluminum casting manufacturing. With advanced facilities in Vietnam and strong Japanese engineering roots, ASUZAC ACM has become a pioneer in applying V-process technology to deliver precision aluminum castings for industries across Asia, Europe, and beyond.

This article provides an in-depth introduction to V-process casting, its fundamental principles, advantages over traditional methods, and the reasons why ASUZAC ACM has emerged as a trusted partner for high-quality aluminum castings.

Table of Contents

What is V-Process Casting?

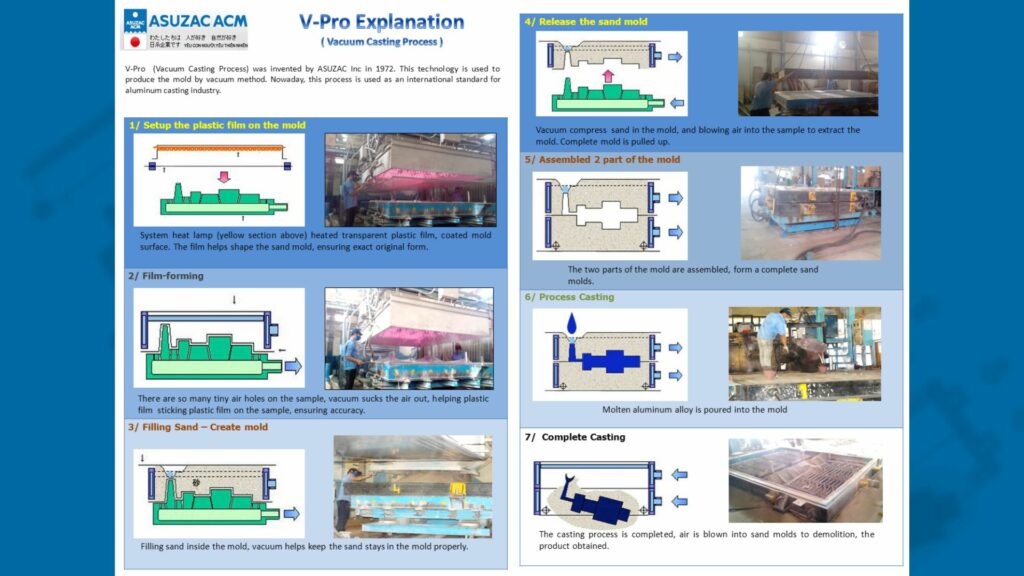

V-process casting is a molding method that uses vacuum pressure to form sand molds without chemical binders. Instead of relying on water or resins to bind the sand, the V-process employs:

- Dry, unbonded silica sand.

- Thin EVA plastic films, heated and vacuum-sealed over patterns.

- Vacuum pressure to harden the sand mold.

This process eliminates the need for chemical binders and produces molds with exceptional stability. The result: castings with excellent surface quality (Ra 12.5) and high dimensional accuracy.

Historical Context and Evolution

The V-process originated in Japan in the 1970s and was quickly adopted in industries that required large, precise, and environmentally friendly castings. Its binder-free nature made it especially attractive in markets facing stricter environmental regulations.

ASUZAC ACM, leveraging its Japanese technology background, introduced and refined the V-process in Vietnam to serve a rapidly industrializing Asian market. Today, ASUZAC ACM is one of the few foundries in Southeast Asia capable of high-volume aluminum V-process casting, positioning itself as an industry leader.

What is V-Process Casting?

V-process casting is a molding method that uses vacuum pressure to form sand molds without chemical binders. Instead of relying on water or resins to bind the sand, the V-process employs:

- Dry, unbonded silica sand.

- Thin EVA plastic films, heated and vacuum-sealed over patterns.

- Vacuum pressure to harden the sand mold.

This process eliminates the need for chemical binders and produces molds with exceptional stability. The result: castings with excellent surface quality (Ra 12.5) and high dimensional accuracy.

Historical Context and Evolution

The V-process originated in Japan in the 1970s and was quickly adopted in industries that required large, precise, and environmentally friendly castings. Its binder-free nature made it especially attractive in markets facing stricter environmental regulations.

ASUZAC ACM, leveraging its Japanese technology background, introduced and refined the V-process in Vietnam to serve a rapidly industrializing Asian market. Today, ASUZAC ACM is one of the few foundries in Southeast Asia capable of high-volume aluminum V-process casting, positioning itself as an industry leader.

Advantages of V-Process Casting

1.Superior Surface Finish and Dimensional Accuracy

The tight adhesion of film to the pattern creates molds with excellent surface smoothness and sharp edges. Typical surface roughness achieved is Ra 12.5, significantly better than green sand molds.

Dimensional tolerances are also more consistent, reducing the need for secondary machining. This translates into lower costs and shorter lead times for customers.

2. Environmentally Friendly Process

Unlike resin-bonded or chemically hardened sand systems, V-process uses no chemical binders. The sand remains clean and can be recycled almost indefinitely. This drastically reduces waste and eliminates harmful emissions, aligning with modern environmental regulations.

For ASUZAC ACM’s clients, this ensures compliance with international sustainability standards and contributes to green manufacturing goals.

3. Flexibility in Design and Materials

V-process is suitable for all metal types—including steel, iron, and non-ferrous alloys. However, ASUZAC ACM focuses on aluminum alloys, due to their lightweight strength and corrosion resistance.

This allows ASUZAC ACM to support industries where reducing weight is critical, such as:

- Automotive manufacturing.

- Railway components.

- Industrial machinery.

- Consumer products.

4. Economic Benefits

- Reduced binder and material costs: no need for resins or chemicals.

- High yield rates: reduced scrap and rework.

- Sand reusability: significant savings in raw material consumption.

In addition, ASUZAC ACM provides pattern design optimization and CAE simulation analysis to improve gating systems, shrinkage compensation, and yield efficiency—ensuring customers receive cost-effective yet precise castings.

Why Choose ASUZAC ACM for V-Process Casting?

Proven Expertise

ASUZAC ACM has decades of expertise in casting technology, backed by Japanese engineering standards. Its facilities in Vietnam integrate state-of-the-art equipment, including:

- Film heating and vacuum systems.

- Automated sand filling and reclamation stations.

- Advanced CAE simulation software for mold design.

- Rigorous inspection and quality control protocols.

End-to-End Solutions

The company offers a full-cycle service, from CAD data analysis and prototype development to large-scale production and final inspection. The pattern developing flow involves close collaboration with customers to ensure that designs are optimized for V-process production.

This structured approach guarantees that every project meets technical, economic, and logistical requirements.

Commitment to Quality and Sustainability

ASUZAC ACM integrates V-process technology into a production philosophy that emphasizes:

- Precision: Dimensional inspections at multiple stages.

- Sustainability: Nearly 100% sand reclamation and binder-free processing.

- Innovation: Continuous equipment upgrades to improve automation and efficiency.

This makes ASUZAC ACM not only a manufacturer but also a strategic partner for industries seeking competitive advantages in quality and sustainability.

Conclusion

V-process casting has redefined the standards of modern foundry technology. Its unique combination of precision, eco-friendliness, and economic efficiency makes it the preferred choice for demanding industries.

By mastering this technology, ASUZAC ACM has become the leading aluminum casting manufacturer in Southeast Asia. With advanced equipment, expert engineering teams, and a customer-first approach, ASUZAC ACM provides castings that are both technically superior and environmentally sustainable.

For businesses seeking reliable, high-quality aluminum castings, ASUZAC ACM stands as a trusted partner and industry leader.