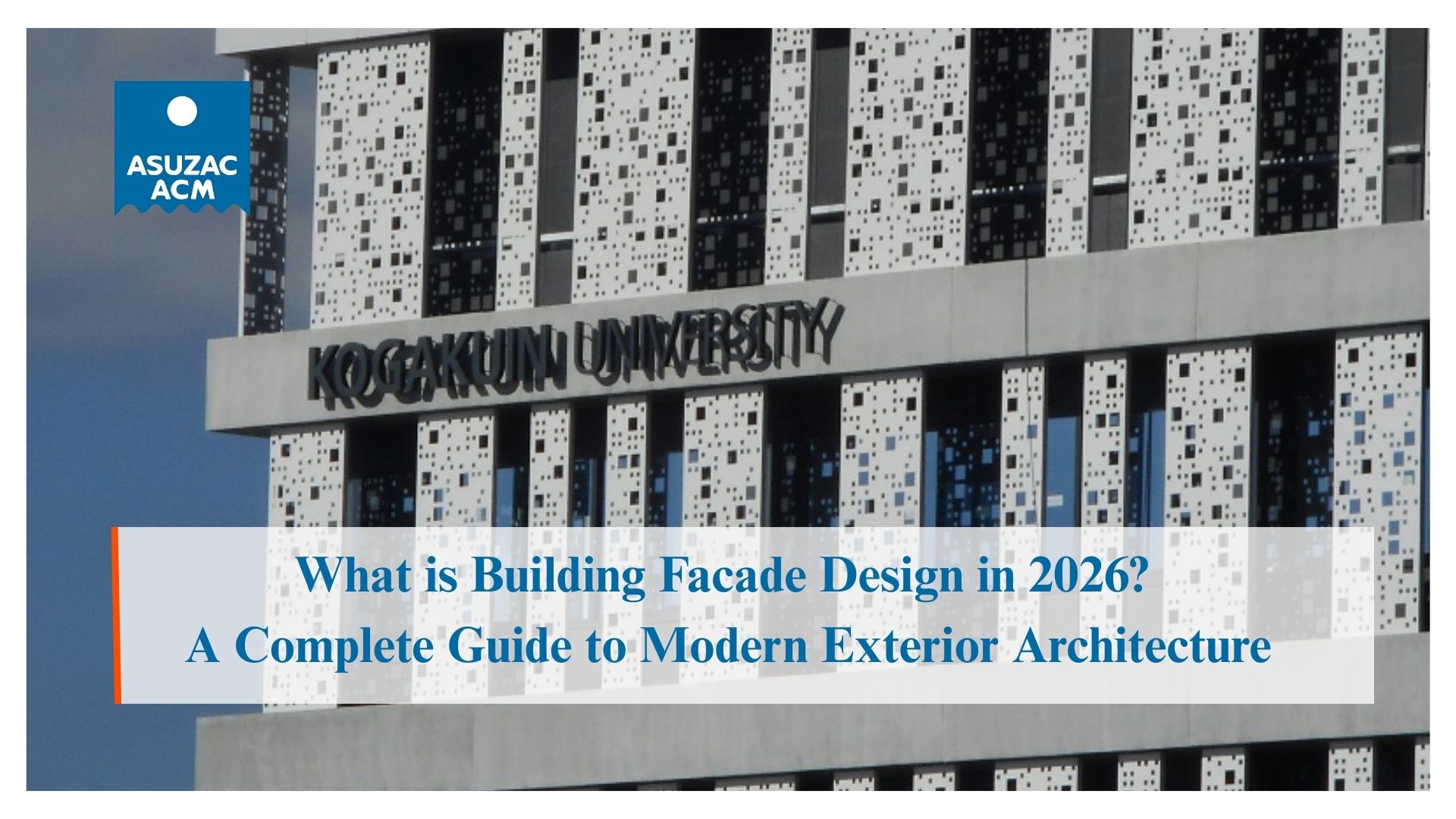

What is Building Facade Design in 2026? A Complete Guide to Modern Exterior Architecture

In 2026, building facade design is no longer just the “outer skin” of a structure — it has become one of the most critical disciplines in architecture, urban planning, and real-estate development.

Today’s facades must simultaneously deliver:

- strong brand identity

- class-A energy performance

- occupant comfort & wellbeing

- resilience against extreme weather

- circular-economy credentials

- photogenic social-media appeal

- long-term economic value (low maintenance + high resale/rental premium)

With global ESG regulations tightening, carbon taxes expanding, and tenants demanding healthier, greener buildings, understanding what is building facade design in 2026 is essential for developers, architects, investors, and facility managers.

This updated 2026 guide explains:

- the modern definition and core purposes of facade design

- the 7 key performance requirements expected today

- why aluminum (especially cast aluminum facade systems) continues to dominate premium projects

- major facade trends shaping 2026–2030

- real-world examples of high-performance aluminum facade projects delivered by ASUZAC ACM, Japan’s leading specialist in precision-cast aluminum architectural components

Table of Contents

What Exactly is Building Facade Design in 2026?

Building facade design is the integrated engineering, material selection, detailing, and artistic treatment of a structure’s vertical (and sometimes roof-edge) exterior surfaces to achieve 6–8 simultaneous objectives:

- Architectural & brand expression — the facade is often the most visible marketing asset

- Climate-adaptive environmental control — solar heat gain, daylight, glare, ventilation, rain & wind protection

- Energy & carbon performance — critical for meeting 2026+ net-zero, LEED v4.1/v5, LOTUS, EDGE, BREEAM, etc. requirements

- Occupant health & wellbeing — views, natural light, acoustic comfort, biophilic connection

- Safety & resilience — wind/seismic/fire performance, blast & impact resistance (where required)

- Lifecycle economics — balancing CAPEX, OPEX, maintenance, and residual value

- Circularity & embodied carbon — low-carbon materials, design for disassembly, high recyclability

- Digital & smart readiness — integration of IoT sensors, dynamic shading, media displays, PV

In short: the facade in 2026 is an active, intelligent system — not a passive wall.

The 7 Core Functions Every 2026 Facade Must Deliver

# | Function | 2026 Typical Target / Standard | Typical Impact on Building Value |

1 | Weather & water tightness | Watertightness > 600 Pa, wind load > 5.0–6.0 kPa | Prevents leaks, mold, structural damage |

2 | Thermal & solar performance | SHGC ≤ 0.25–0.35, U-value ≤ 1.0–1.8 W/m²K | 20–50% reduction in cooling energy |

3 | Daylight & glare management | Daylight Autonomy 50–70%, DGP < 35–40% | Higher productivity, lower electric lighting use |

4 | Natural ventilation & fresh air | Hybrid or operable elements | Better IAQ, reduced mechanical ventilation costs |

5 | Acoustic insulation | Rw ≥ 38–48 dB (traffic / aircraft noise) | Critical for urban high-rises |

6 | Fire & life safety | A1/A2-s1,d0 non-combustible or limited combustibility | Regulatory compliance, lower insurance premiums |

7 | Aesthetic & market appeal | Custom textures, lighting, biophilic elements | 5–15% higher rental/sale price in premium segments |

Aluminum systems — especially cast aluminum facade panels and integrated aluminum louvers — consistently rank among the best-performing solutions across most categories.

Why Aluminum (Especially Cast Aluminum) Remains #1 in Facade Design in 2026

Aluminum continues to dominate high-end facade projects globally because it offers:

- Best-in-class strength-to-weight ratio

- Outstanding corrosion resistance (especially 5xxx & 6xxx marine-grade alloys)

- Closed-loop recyclability (>95% recovery rate)

- Compatibility with advanced finishes (2- & 3-coat 70% PVDF, FEVE powder, anodizing)

- Multiple fabrication routes: extrusion, sheet fabrication, precision casting

Among aluminum facade technologies, cast aluminum facade panels (produced via vacuum precision casting) deliver:

- largest seamless panel sizes

- deepest 3D relief & parametric textures

- monolithic structural behavior (no weak joints)

- perfect surface quality for coating adhesion

ASUZAC ACM – Japan’s Leading Cast Aluminum Facade Specialist

ASUZAC ACM is widely regarded as Japan’s foremost expert in precision-cast aluminum architectural components and facade systems.

A 100% Japanese-owned company under the ASUZAC Group (founded 1946), ASUZAC ACM has operated its advanced Vietnam factory since 2005. The company’s signature V-Process Technology — a vacuum-assisted casting method — produces panels with:

- mirror-smooth surfaces

- zero internal porosity

- exceptional dimensional accuracy (±0.2 mm tolerance achievable)

- ability to cast large monolithic panels and complex 3D reliefs

All facade products are finished exclusively with AAMA 2605-compliant premium PPG coatings — the global gold standard for architectural aluminum — ensuring color fade ≤5 ΔE, chalk rating ≤8, and film integrity after 10 years of intense South Florida-equivalent exposure.

PPG Premium Coating Systems Used by ASUZAC ACM

ASUZAC ACM partners only with PPG Industries — the inventor of 70% PVDF architectural coatings — and applies three flagship systems across all facade projects:

- PPG DURANAR® Liquid 70% PVDF Coatings

- 2-coat or 3/4-coat (XL version for aggressive environments)

- Proven since 1965 — real-world exposure data >50 years

- Color change ≤5 ΔE, chalk ≤8 after 10 years South Florida

- Ideal for deep tones, exact color matching, and high-gloss/metallic finishes

- Read more: PPG Liquid Coatings for Architectural Aluminum

- PPG Coraflon® Platinum FEVE Powder Coatings

- Single-coat FEVE system — no primer/topcoat needed

- Broader gloss range (5–85), true anodized-look finishes, 20% higher transfer efficiency

- 100% reclaimable, zero VOCs/HAPS/BPA/TGIC/PFOA

- Outstanding single-coat corrosion resistance

- Read more: PPG Coraflon Platinum FEVE Powder Coatings

- Liquid vs Powder Comparison

- Liquid (DURANAR®) excels in color-critical matching and deep tones

- Powder (Coraflon® Platinum) excels in sustainability, matte/anodized looks, and production efficiency

- Both achieve full AAMA 2605 performance when applied correctly

- Read more: PPG Liquid vs Powder Coatings Comparison

By combining V-Process casting (perfect substrate) with PPG AAMA 2605 coatings (ultimate protection), ASUZAC ACM guarantees facades that remain vibrant and maintenance-free for 30+ years — even in Vietnam’s aggressive tropical climate.

Major Facade Design Trends in 2026–2030

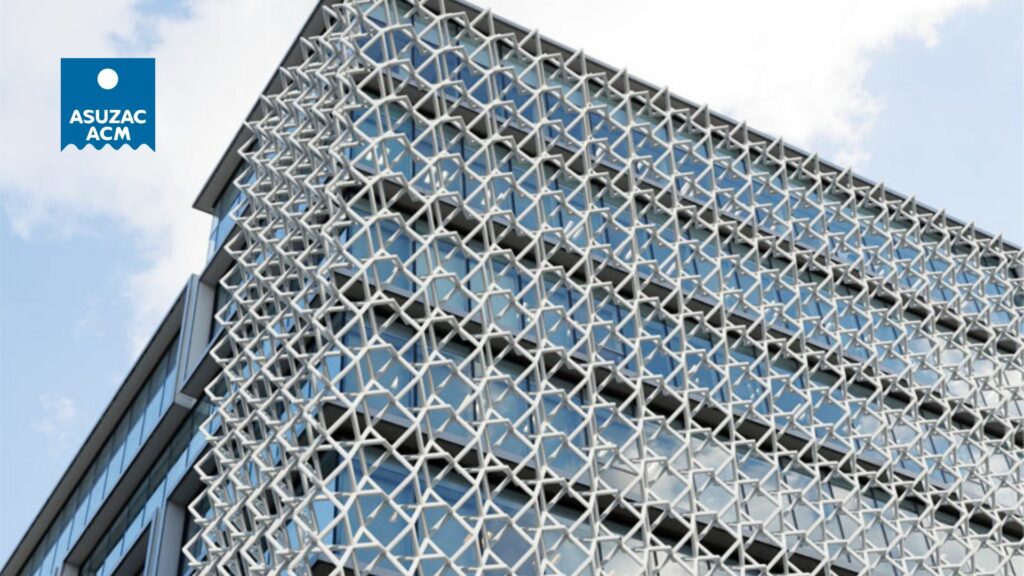

- Adaptive & Bioclimatic Facades — Louvers, perforated cast panels, and kinetic elements that respond to sun path and wind

- Ultra-Large Monolithic Panels — Fewer joints, cleaner lines, faster installation

- Parametric & Data-Driven Textures — 3D reliefs generated by algorithms for light-shadow dynamics

- Circular & Low-Carbon Focus — 100% recyclable aluminum + low-embodied-carbon coatings

- Hybrid Systems — Aluminum cast elements combined with PV glass, vertical gardens, media displays

- Cultural & Identity Expression — Local motifs cast directly into metal surfaces (e.g., lotus, bamboo, geometric patterns inspired by regional heritage)

ASUZAC ACM’s cast aluminum systems excel particularly in trends #2, #3, and #6.

Contact ASUZAC ACM – Your Trusted Partner for Next-Generation Aluminum Facades

Ready to create a facade that defines the future?

- Phone: +84-937-076-608

- Email: [email protected]

- Website: Contact Us

- Address: No. 1A, Road No. 8, Vietnam – Singapore Industrial Park, Binh Hoa Ward, Ho Chi Minh City

Facade Design is the New Frontier

What is building facade design in 2026? It is performance art, environmental engineering, brand identity, and legacy creation — all in one intelligent system.

Companies like ASUZAC ACM — proven on projects such as Ho Chi Minh City Metro Line 1 and Kogakuin University — are helping architects worldwide turn ambitious visions into built reality with cast aluminum facade systems that are beautiful, intelligent, and built to last.